A kind of preparation method of thermoelectric power generation material

A thermoelectric power generation and weighing technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device junction lead-out materials, etc., can solve the problems of low electrical conductivity, low thermoelectric conversion efficiency, high thermal conductivity, etc., to reduce thermal conductivity efficiency, good electron mobility, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

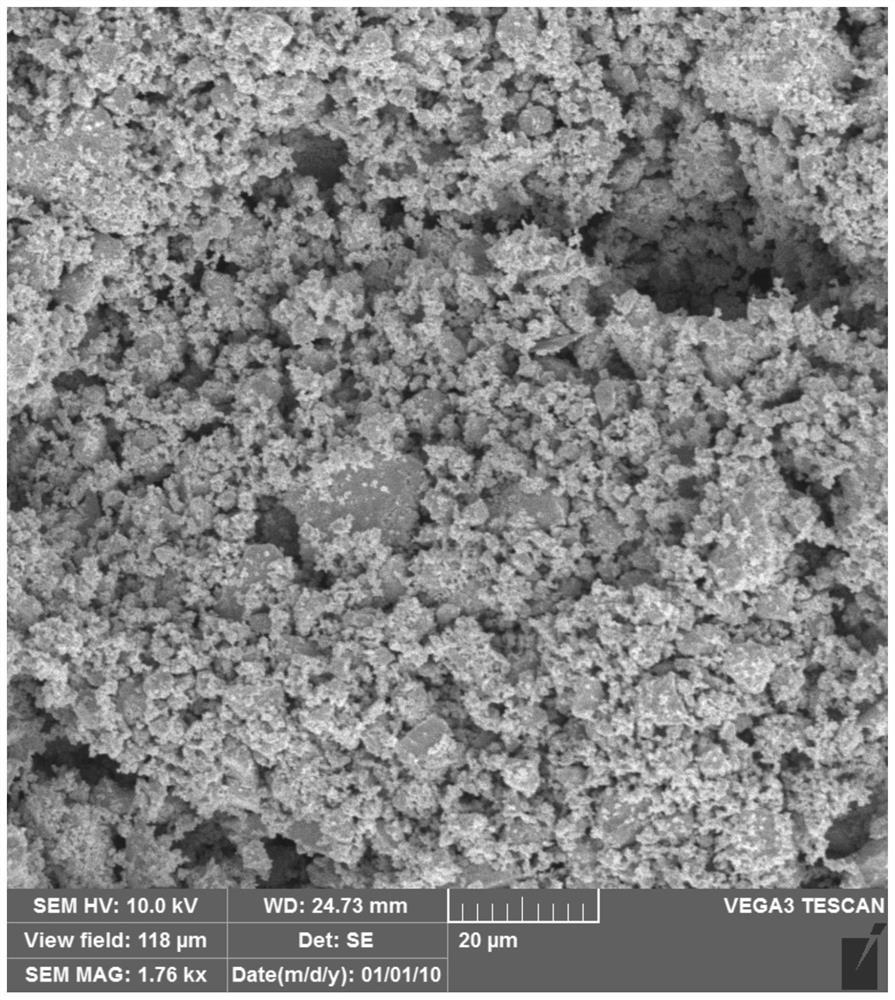

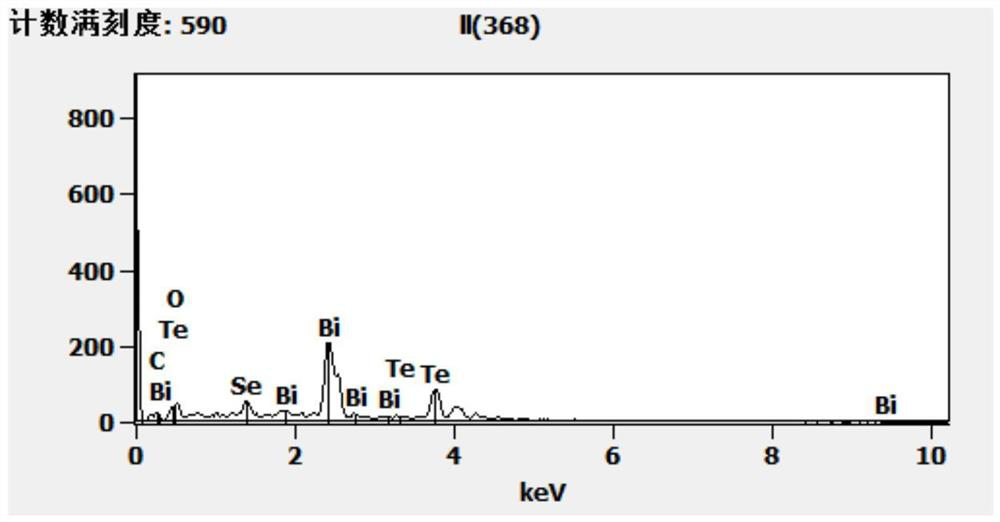

[0037] Specific embodiment 1: In this embodiment, a method for preparing a thermoelectric power generation material is carried out according to the following steps:

[0038] 1. Weighing:

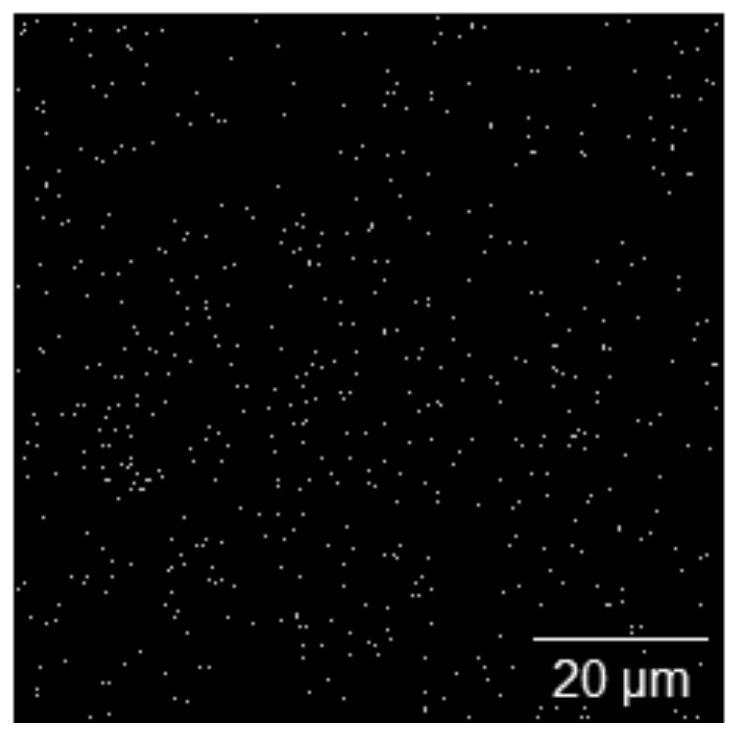

[0039] According to the general structural formula as Bi 2 Te 2.7 Se 0.3-xThe stoichiometric ratio of bismuth powder, tellurium powder and selenium powder is weighed; wherein 0.01≤x≤0.05; silicon carbide nanowires are weighed, and the quality of silicon carbide nanowires is 0% to 0% of the total mass of bismuth powder, tellurium powder and selenium powder 0.8%;

[0040] 2. Ball milling:

[0041] Place the bismuth powder, tellurium powder, selenium powder and silicon carbide nanowires weighed in step 1 in a ball milling jar, add grinding aids and grinding balls, seal the ball milling jar, inject nitrogen after vacuuming, and then vacuumize, and finally Under the condition of rotating speed of 300rpm-500rpm, grind for 8h-10h to obtain the product after ball milling;

[0042] 3. Heat trea...

specific Embodiment approach 2

[0058] Embodiment 2: This embodiment differs from Embodiment 1 in that the grinding aid described in step 2 is absolute ethanol. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0059] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, the ball-to-material ratio is (14-21):1 and the balls are put into the grinding ball. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com