Graphene foam and preparation method thereof, graphene carbon composite material and preparation method thereof

A graphene foam and composite material technology, applied in the direction of graphene, carbon compounds, heat exchange materials, etc., can solve the problems of lack of strong directional thermal conductivity and low thermal conductivity, and achieve improved thermal conductivity and high thermal conductivity. , the effect of improving the thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0071] As a third embodiment of the present invention, a graphene-carbon composite material is provided, including graphene and a carbon material filled between graphene layers. The density of graphene carbon composite material is 1.0-2.2g / cm 3 , for example: 1.0g / cm 3 , 1.1g / cm 3 , 1.2g / cm 3 , 1.3g / cm 3 , 1.4g / cm 3 , 1.5g / cm 3 , 1.6g / cm 3 , 1.7g / cm 3 , 1.8g / cm 3 , 1.9g / cm 3 , 2.0g / cm 3 , 2.1g / cm 3 , 2.2g / cm 3,Wait. The mass fraction of graphene in the graphene-carbon composite material is 5-80wt%, for example: 5wt%, 6wt%, 7wt%, 8wt%, 9wt%, 10wt%, 12wt%, 15wt%, 20wt%, 25wt%, 30wt% %, 35wt%, 40wt%, 45wt%, 50wt%, 55wt%, 60wt%, 65wt%, 70wt%, 72wt%, 75wt%, 78wt%, 79wt%, 80wt%, etc., the mass fraction of carbon material is 20 -95wt%, for example: 20wt%, 21wt%, 22wt%, 25wt%, 28wt%, 30wt%, 35wt%, 40wt%, 45wt%, 50wt%, 55wt%, 60wt%, 65wt%, 70wt%, 75wt% , 80wt%, 85wt%, 88wt%, 90wt%, 91wt%, 92wt%, 93wt%, 94wt%, 95wt%, etc. The thermal conductivity of graphene carbon compo...

Embodiment 1A

[0077] This example shows the preparation process of the plate-shaped graphene foam.

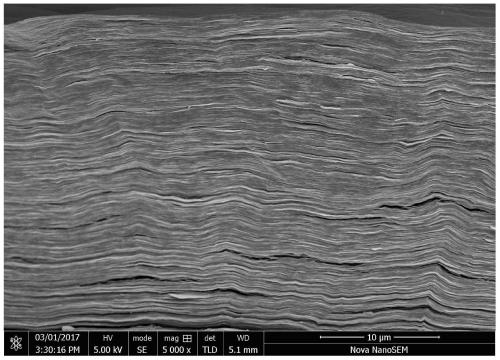

[0078] Step 1): Cut the in-plane oriented assembled graphene oxide film with a thickness of 200 μm into sheets, and the cross-sectional SEM image of the graphene oxide film is shown in figure 1 shown.

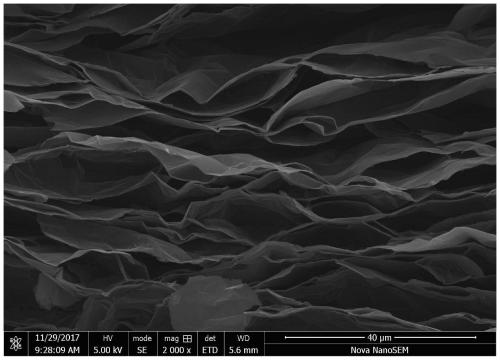

[0079] Step 2): sandwich the graphene oxide sheet between two graphite papers, put it into a high-temperature furnace, and raise the temperature to 400°C at a rate of 0.1°C / min in an air environment; replace the air with nitrogen, and heat up to 2°C Raise the temperature to 1000°C at a rate of / min to obtain a thickness of 0.5mm and a density of 0.15g / cm 3 , graphene foam with a thermal conductivity of 150W / m K, the SEM image of graphene foam figure 2 shown.

Embodiment 1B

[0081] This example shows the preparation process of using the graphene foam of Example 1A to prepare a plate-shaped graphene-carbon composite material.

[0082] Step 1): Put the graphene foam into a high-temperature and high-pressure impregnation carbonization furnace, add coal tar pitch, adjust the pressure in the furnace to 100MPa, raise the temperature to 450°C at a rate of 10°C / min, and keep it warm for 1h; The temperature was raised to 570°C at a rate of 1 min, and the temperature was kept for 2 hours to obtain a composite material of composite carbon material between the inner layers of the graphene foam.

[0083] Step 2): Put the composite material of the graphene foam inner interlayer composite carbon material in step 1) into a graphitization furnace, heat up to 1800°C at a rate of 10°C / min, and heat treatment time is 3h; at 5°C / min The temperature is raised to 2850°C at a high rate, and the heat treatment time is 3h, and the thickness is 0.5mm, the density is 1.6g / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com