Thermally-conductive polybutylene succinate ionomer and preparation method and application thereof

A polybutylene succinate and ionomer technology, which is applied in the field of thermally conductive polybutylene succinate ionomer and its preparation, can solve the problems of low viscosity and melt strength, reduced material mechanical properties, Limit application and other issues, to achieve the effect of high melt viscosity and strength, good processing performance, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

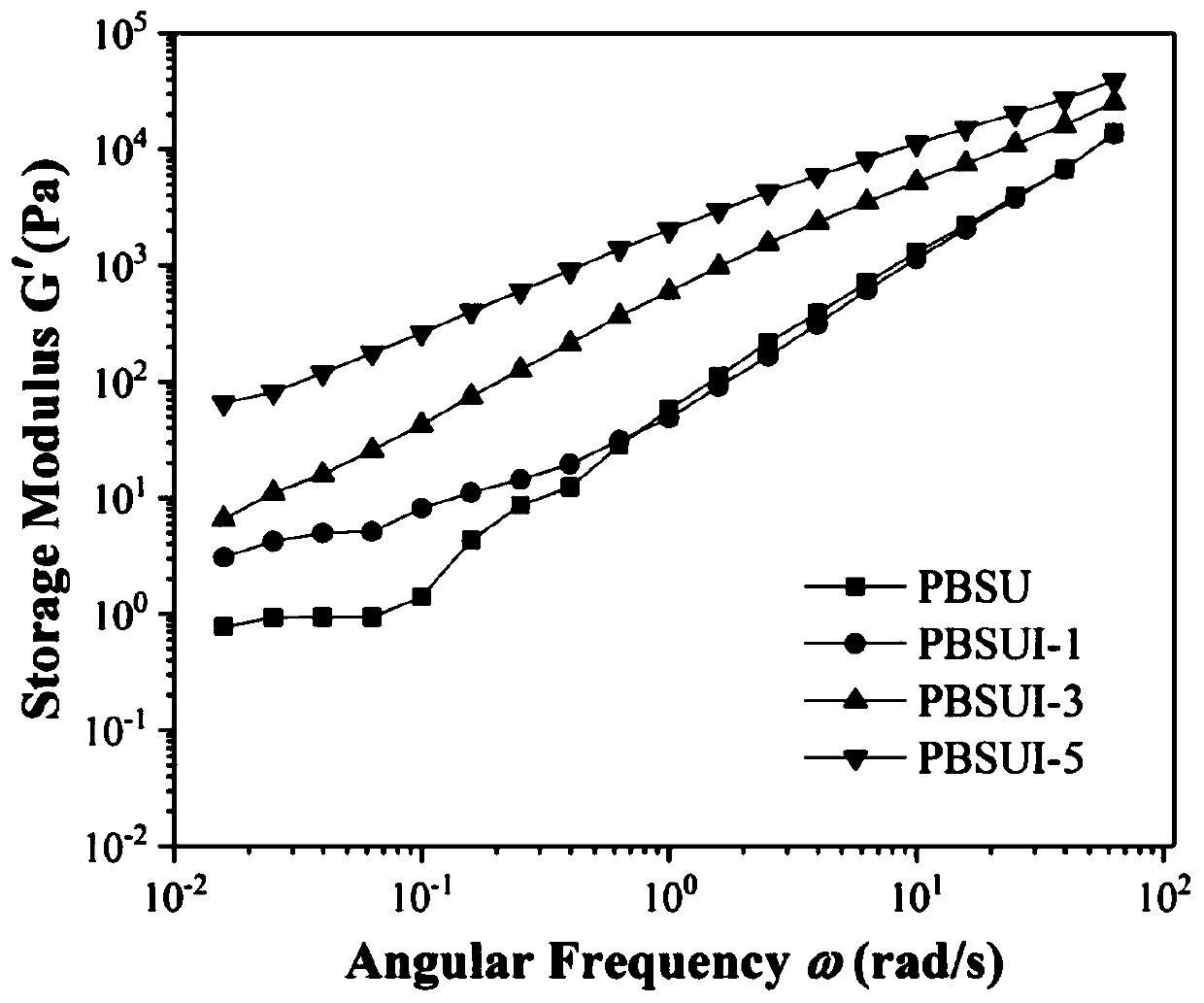

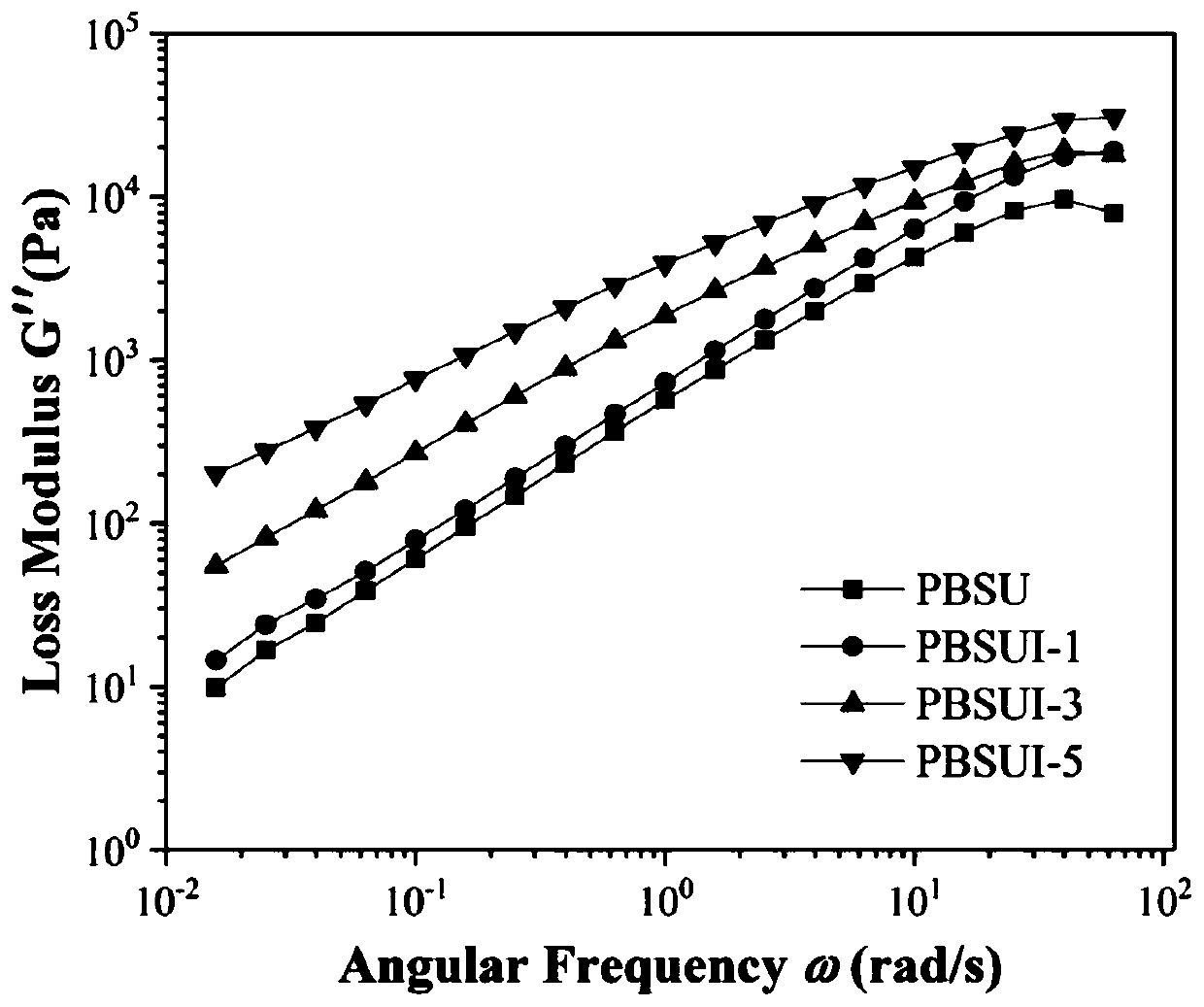

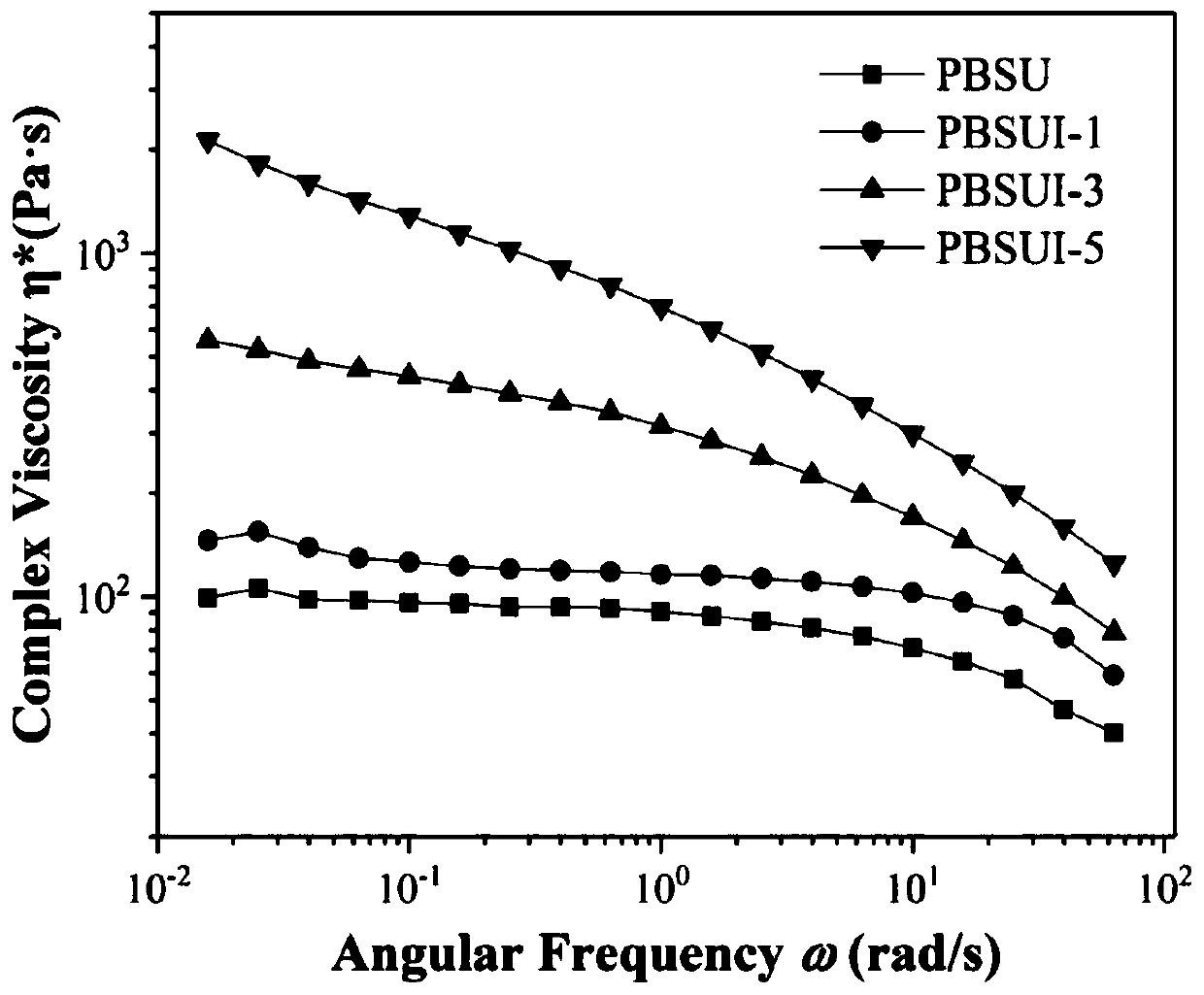

Embodiment 1

[0047] Before the esterification, feed dry nitrogen into the flask, replace the air in the bottle, and repeat 5 times to remove the air in the bottle, and the system is under the protection of nitrogen. Alcohol (BD, 1.2 mole parts) was mixed, and then the system was heated to 180°C under stirring, and the temperature was maintained until the collected by-product water was close to the theoretical value, and then 1000ppm of titanic acid relative to the total mass of succinic acid and butanediol was added Tetrabutyl ester is used as a catalyst, and the reaction temperature is raised to 210°C while vacuuming, and reacted for 1.5h to obtain a polybutylene succinate prepolymer, then the reaction temperature is lowered to 140°C, and polybutylene succinate is added The diethanolamine hydrochloride of glycol ester prepolymer quality 0.01 is as ionic monomer, vacuumizes reaction 2h, logical nitrogen and adds the chain extender (chain extender) that accounts for polybutylene succinate pr...

Embodiment 2

[0049] Before the esterification, feed dry nitrogen into the flask, replace the air in the bottle, and repeat 5 times to remove the air in the bottle, and the system is under the protection of nitrogen. Alcohol (BD, 1.2 mole parts) was mixed, and then the system was heated to 180°C under stirring, and the temperature was maintained until the collected by-product water was close to the theoretical value, and then 1000ppm of titanic acid relative to the total mass of succinic acid and butanediol was added Tetrabutyl ester is used as a catalyst, and the reaction temperature is raised to 210°C while vacuuming, and reacted for 1.5h to obtain a polybutylene succinate prepolymer, then the reaction temperature is lowered to 140°C, and polybutylene succinate is added The diethanolamine hydrochloride of glycol ester prepolymer quality 0.03 is as ionic monomer, vacuumizes reaction 2h, logical nitrogen and adds the chain extender (chain extender) that accounts for polybutylene succinate pr...

Embodiment 3

[0051] Before the esterification, feed dry nitrogen into the flask, replace the air in the bottle, and repeat 5 times to remove the air in the bottle, and the system is under the protection of nitrogen. Alcohol (BD, 1.2 mole parts) was mixed, and then the system was heated to 180°C under stirring, and the temperature was maintained until the collected by-product water was close to the theoretical value, and then 1000ppm of titanic acid relative to the total mass of succinic acid and butanediol was added Tetrabutyl ester is used as a catalyst, and the reaction temperature is raised to 210°C while vacuuming, and reacted for 1.5h to obtain a polybutylene succinate prepolymer, then the reaction temperature is lowered to 140°C, and polybutylene succinate is added The diethanolamine hydrochloride of glycol ester prepolymer quality 0.05 is as ionic monomer, vacuumizes reaction 2h, logical nitrogen and adds the chain extender (chain extender) that accounts for polybutylene succinate pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com