Method for preparing silicon nitride/silicon oxide composite crucible

A composite crucible and silicon oxide technology, applied in chemical instruments and methods, crystal growth, single crystal growth and other directions, can solve the problems of high cost of crucibles and low production success rate, and achieve the effects of improving quality, improving quality and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

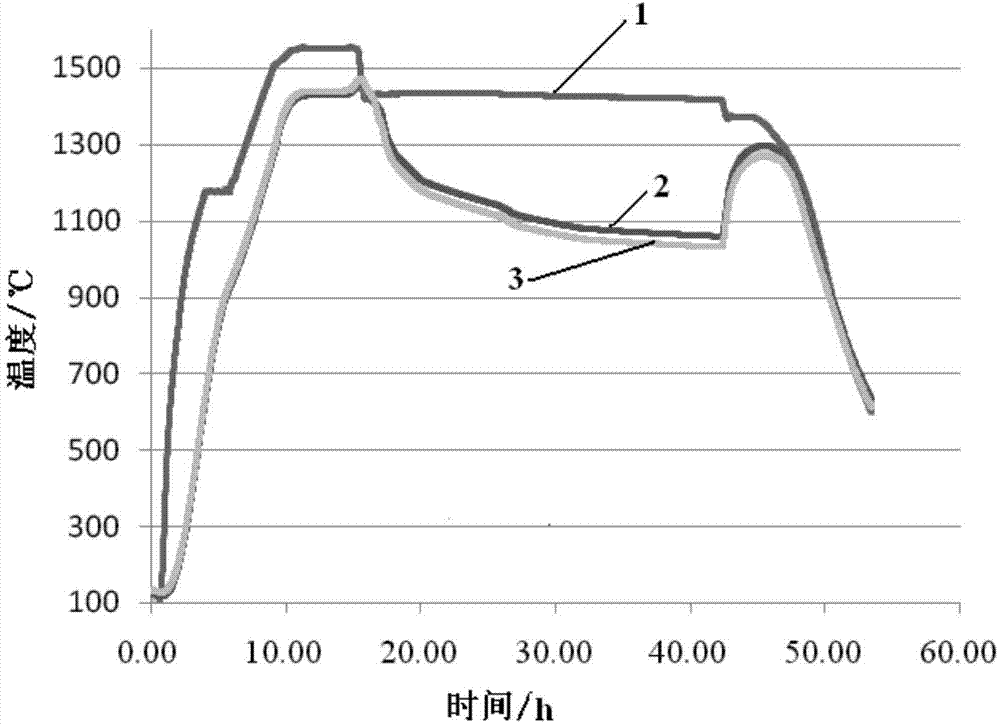

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: the preparation method of a silicon nitride / silicon oxide composite crucible in this embodiment is carried out according to the following steps:

[0020] 1. Preparation of bottom slurry: uniformly mix silicon nitride powder and quartz powder to obtain ceramic powder, and wet-mix ball mill the ceramic powder in a polyurethane ball mill tank for 12h to 16h to obtain uniform mixed ceramic powder. The mixed ceramic powder is uniformly stirred and mixed with water, crosslinking agent I and initiator I to obtain slurry I, and then the pH value of slurry I is adjusted to 3 to 4 with lactic acid or ammonia water to obtain slurry II; The mass ratio of the silicon nitride powder to the quartz powder is 1: (2.3-99); the mass ratio of the mixed ceramic powder to water in the step 1 is 1: (0.3-0.6), and the mass ratio in the step 1 The mass ratio of the crosslinking agent I to the mixed ceramic powder is 1: (60-70), and the mass ratio of the initiator I to t...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the crosslinking agent I in Step 1 is acrylamide. Others are the same as the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the initiator I in step 1 is ammonium persulfate. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com