Continuous fiber reinforced high-entropy ceramic matrix composite material and preparation method thereof

A composite material and continuous fiber technology, which is applied in the field of continuous fiber reinforced high-entropy ceramic matrix composite materials and their preparation, can solve problems such as defect sensitivity, high brittleness, and limited engineering applications, and achieves low preparation temperature, simple equipment and process, and wide The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing continuous fiber reinforced high-entropy ceramic matrix composites:

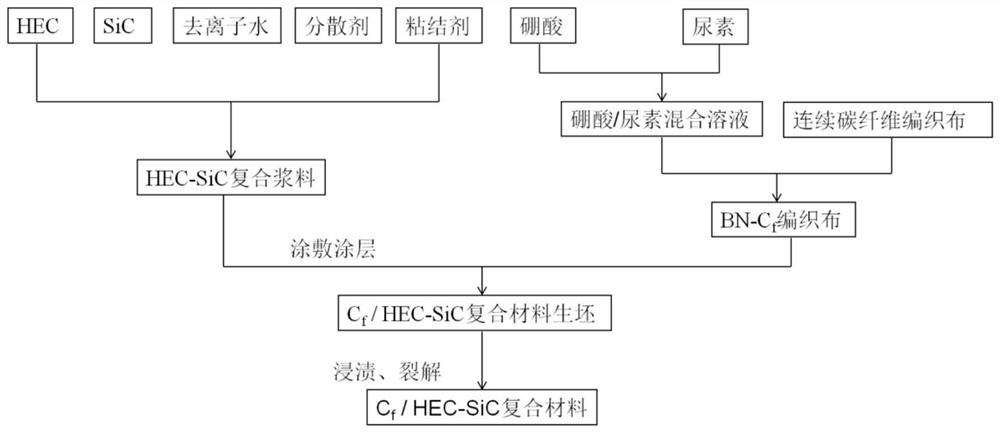

[0037] For the preparation flow chart, see figure 1 ;

[0038] (1) Mix TiC, ZrC, HfC, NbC, and TaC in equal molar proportions by ball milling, and heat at 2000°C for 1 hour to obtain high-entropy ceramic powder (HEC); 258.6g high-entropy ceramic powder (HEC), 78.4g silicon carbide Ceramic powder (SiC), 50g deionized water, 2.5g polyethylene glycol (dispersant PEG), and 2g methylcellulose (binder MC) are mixed and put into a ball mill jar, and the speed is 400r on a planetary ball mill / min ball milling for 3 hours to obtain a uniformly dispersed HEC-SiC composite slurry.

[0039] (2) Put 120g of boric acid, 40g of urea, 40g of deionized water, and 40g of absolute ethanol into a ball mill jar after mixing, and ball mill for 3 hours on a planetary ball mill at a speed of 400r / min to obtain a uniformly dispersed boric acid / urea mixed solution.

[0040] (3) The continuous carbon ...

Embodiment 2

[0044] Same as Example 1, the difference is that the amount of high-entropy ceramic powder is 187.2g, and the amount of silicon carbide ceramic powder is 133.8g;

[0045] The porosity of the prepared high-entropy ceramic matrix composite is 10%, and the bending strength is 200MPa.

Embodiment 3

[0047] With embodiment 1, difference is that the layer thickness in step (4) is 0.5mm;

[0048] The porosity of the prepared high-entropy ceramic matrix composite is 15%, and the bending strength is 150Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com