Continuous production system for laminated biomass composite material and application method thereof

A composite material and production system technology, applied in the field of composite materials, to achieve the effects of stable product production, high efficiency and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

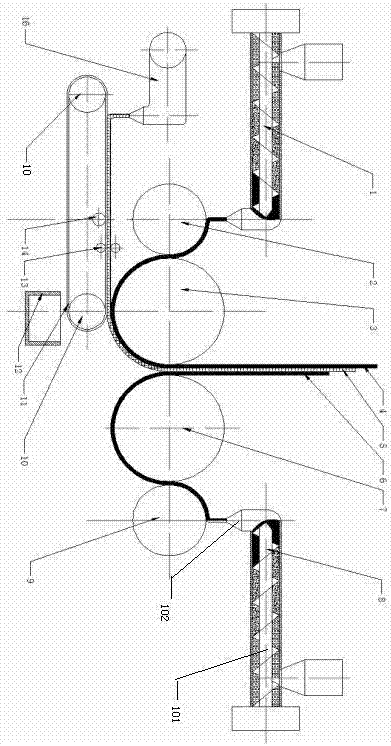

[0042] Such as figure 1 As shown, the continuous production system of laminated biomass composite materials provided in this embodiment includes melt film forming device 1, fiber material conveying device and melt film conveying device 2;

[0043] Melt film molding device one comprises screw extruder 1, forming roll one 2 and cylinder one 3 pressed with forming roll one 2; The conveying device, the three-dimensional vibrator 14 is arranged below the conveying device; the conveying device includes a conveyor belt 11 and a pair of dispersing rollers 13 arranged on the upper and lower sides of the conveyor belt 11 .

[0044] The roller body 10 rotates in cooperation with the roller one 3, and it is set to press the fiber material and the polymer melt film into one.

[0045] The melt film conveying device two includes a screw extruder 8, a forming roller two 9 and a roller two 7 pressed together with the forming roller two 9, and the roller two 7 rotates in cooperation with the rol...

Embodiment 2

[0051] The method for using the continuous production system of the laminated biomass composite material of the present embodiment comprises the following steps:

[0052] S1. Put the polymer material A in the screw extruder 1, extrude the polymer material A on the forming roller 1 through melting and plasticizing, press the forming roller 2 and the roller 3, and form the forming roller 2 Heating to 30~300°C with roller one 3, pressing the polymer material A to form a polymer melt film A4 in a molten state;

[0053] S2. At the same time, add the biomass fiber material to the biomass fiber material conveying device, drive the conveying device through the roller body 10, open the three-dimensional vibrator 14 and the dispersion roller 13 below the conveying device, and convey the biomass fiber material to the roller body 10 Between the roller 10 and the roller 3, there is a certain pressure and action angle between the roller body 10 and the roller 3, so that the biomass fiber ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com