Sintering method of aluminum nitride ceramic substrate

A technology of aluminum nitride ceramics and sintering method, applied in the field of aluminum nitride preparation, can solve the problems of affecting materials, difficult to control the stability of thermal conductivity of substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

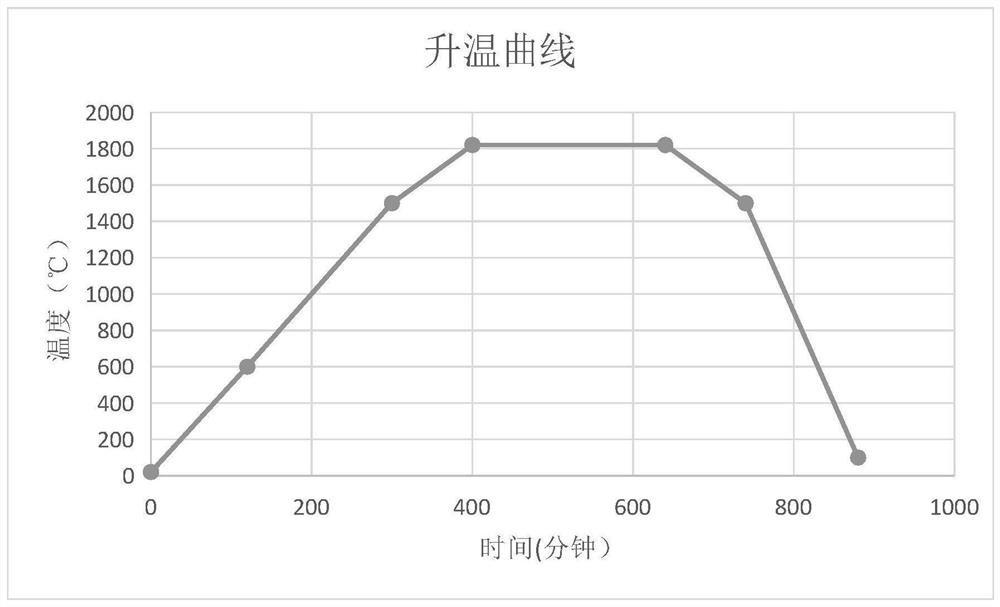

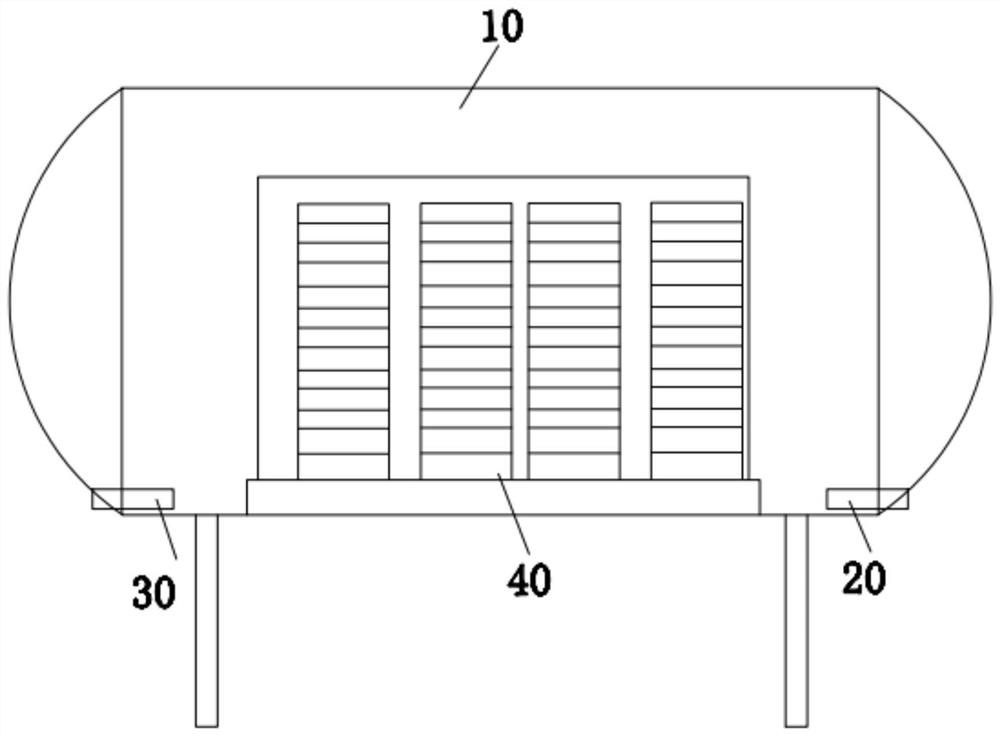

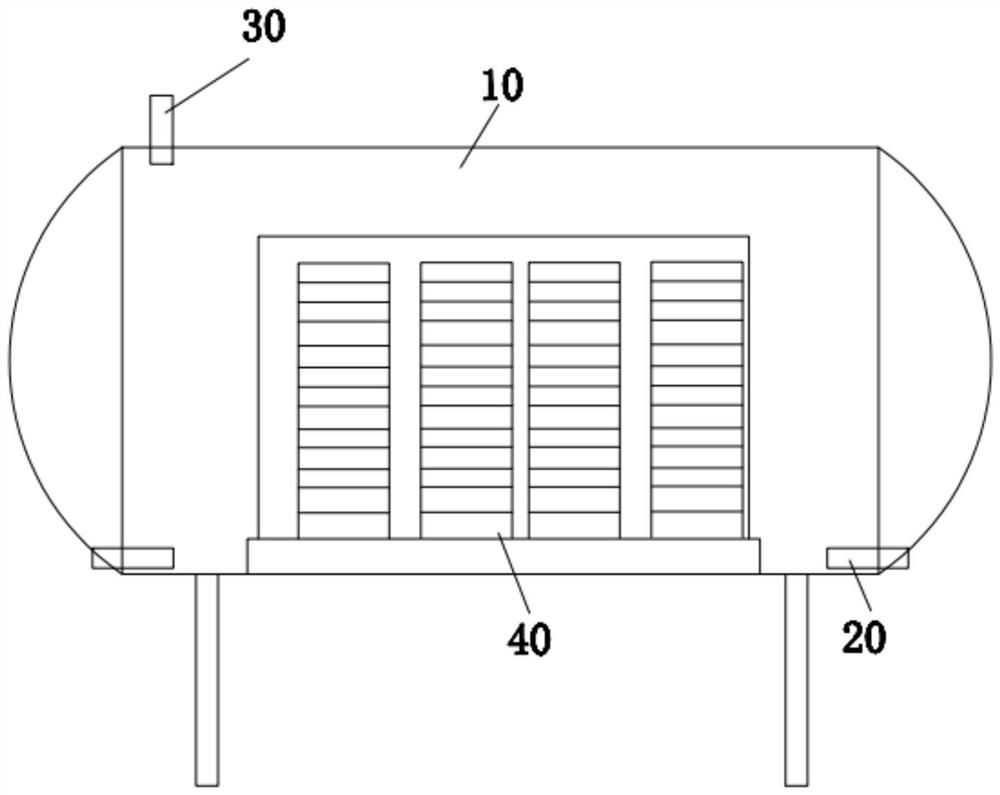

[0047] Sinter the aluminum nitride ceramic substrate according to the following process, backfill high-purity nitrogen after vacuuming to 100Pa, and the backfilling speed is 3m 3 / h, backfilling is completed after 2 hours, the furnace pressure is 0.2MPa, close the backfill valve 30, start heating, increase the temperature to the sintering temperature of 1815°C according to the curve, keep the temperature for 4 hours and then cool down. After starting heating, open the vent valve 20 every 60 minutes during the sintering process, release the pressure to 0.1MPa, close the vent valve 20, open the backfill valve 30, and then 3 Backfill nitrogen to 0.2MPa at a speed of / h, and cycle repeatedly. After the sintering is completed, it is released from the furnace, and after the interlayer powder on the surface of the substrate is removed, the flatness and thermal conductivity of the substrate are measured.

Embodiment 2

[0049] Sinter the aluminum nitride ceramic substrate according to the following process, backfill high-purity nitrogen after vacuuming to 50Pa, and the backfilling speed is 4m 3 / h, backfilling is completed after 1.5 hours, the furnace pressure is 0.2MPa, close the backfill valve 30, start heating, increase the temperature to the sintering temperature of 1810°C according to the curve, keep the temperature for 4 hours and then cool down. After starting to heat, open the vent valve 20 every 30 minutes during the sintering process, release the pressure to 0.1MPa, close the vent valve 20, open the backfill valve 30, and then pressurize at 2m 3 Backfill nitrogen to 0.2MPa at a speed of / h, and cycle repeatedly. After the sintering is completed, it is released from the furnace, and after the interlayer powder on the surface of the substrate is removed, the flatness and thermal conductivity of the substrate are measured.

Embodiment 3

[0051] Sinter the aluminum nitride ceramic substrate according to the following process, backfill high-purity nitrogen after vacuuming to 10Pa, and the backfilling speed is 2m 3 / h, backfilling is completed after 3 hours, the furnace pressure is 0.2MPa, close the backfill valve 30, start heating, heat up to the sintering temperature of 1820°C according to the curve, keep the temperature for 4h and then cool down. After starting heating, open the vent valve 20 every 30 minutes during the sintering process, release the pressure to 0.1MPa, close the vent valve 20, open the backfill valve 30, and then 3 Backfill nitrogen to 0.2MPa at a speed of / h, and cycle repeatedly. After the sintering is completed, it is released from the furnace, and after the interlayer powder on the surface of the substrate is removed, the flatness and thermal conductivity of the substrate are measured.

[0052] The performance parameters of the substrates obtained by sintering in the above three embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com