Heat conduction-wave absorption integrated material as well as preparation method and application thereof

A wave-absorbing filler and matrix technology, which is applied in the field of heat conduction-microwave absorption, can solve problems such as narrow absorption bandwidth, difficulty in controlling shape and size, and cumbersome experimental steps, and achieve excellent heat conduction and wave absorption performance, good industrial application potential, The preparation process is simple and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A preparation method of a heat conduction-wave absorbing integrated material, specifically comprising the following steps:

[0056] Mix 0.3g of nano-titanium dioxide and 0.5mL of iron pentacarbonyl evenly and spread it in the quartz ark; then wrap the quartz ark completely with double-layer tin foil, and place it in a tube furnace. The heating rate of min was raised to 250°C, after holding for 1 hour, the temperature was raised to 400°C at a heating rate of 5°C / min, and after holding for 1 hour, it was cooled to room temperature and taken out to obtain the thermally conductive wave absorbing filler;

[0057] The thermally conductive wave-absorbing filler obtained above is filled into a silicone oil matrix in a certain proportion to prepare a silicone film: first, 0.48g of hydrogen-containing silicone oil, 1.5g of vinyl silicone oil, 0.005g of inhibitor and 0.6g of ethanol are weighed and stirred in a container for 30min , then add 0.02g of catalyst and stir for 5 minute...

Embodiment 2

[0062] Compared with the preparation steps disclosed in Example 1, the only difference is that the mass of iron pentacarbonyl added is 0.25mL, and the other preparation steps and process parameters are the same.

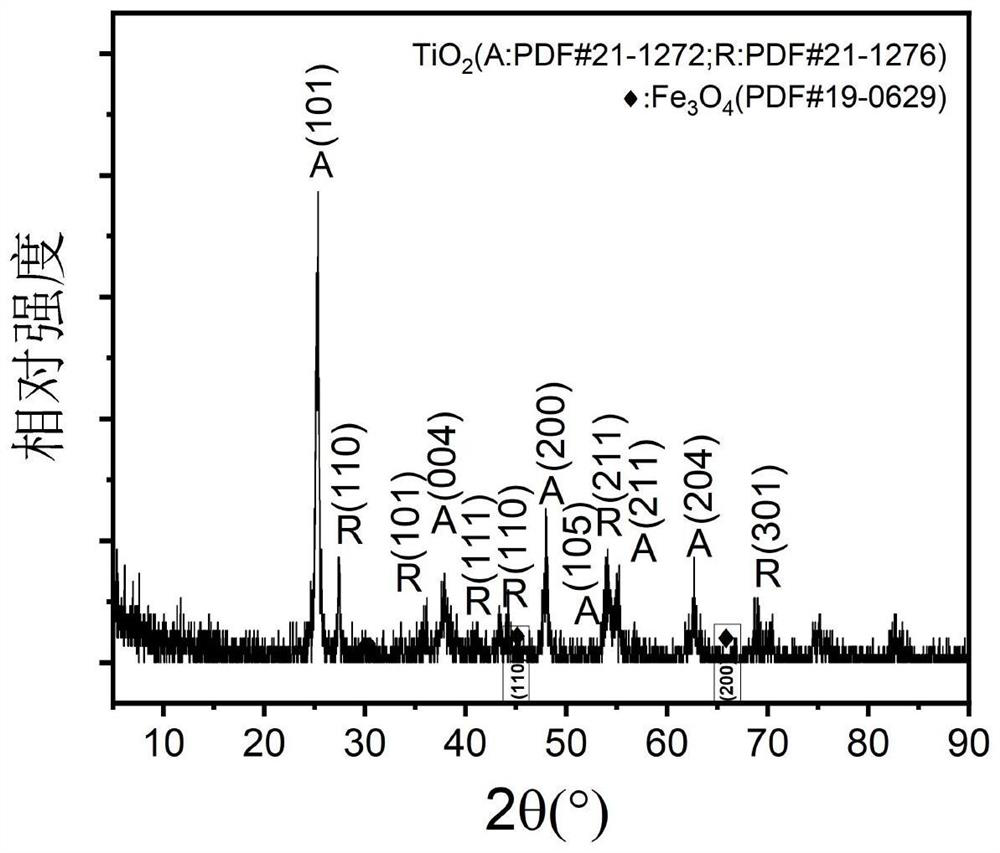

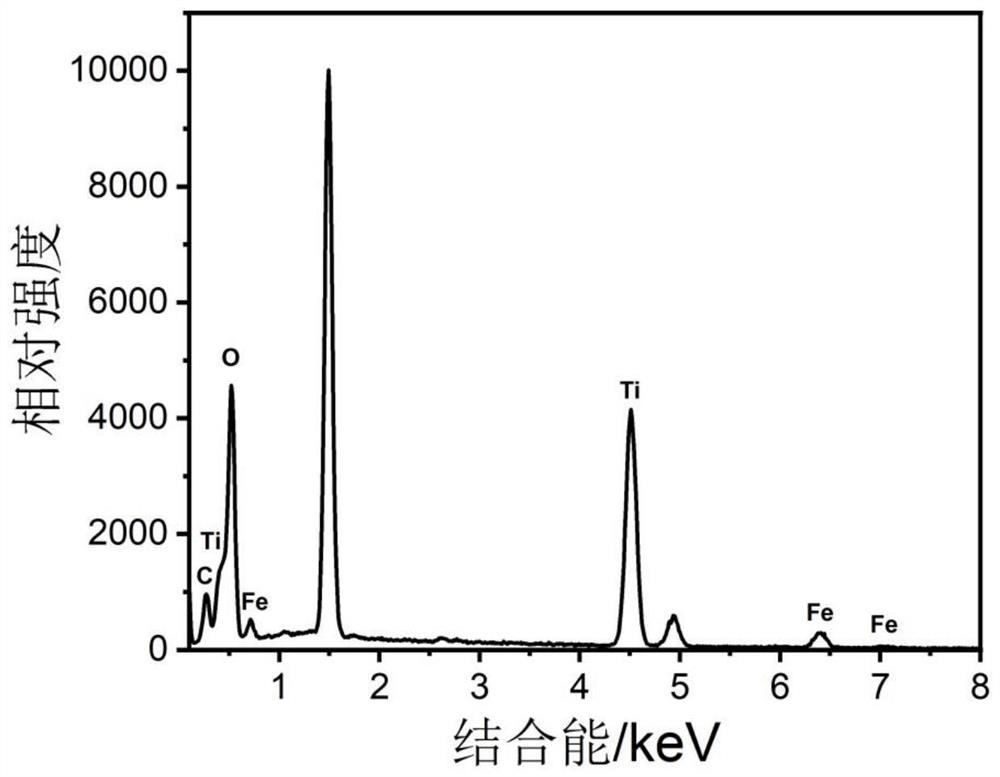

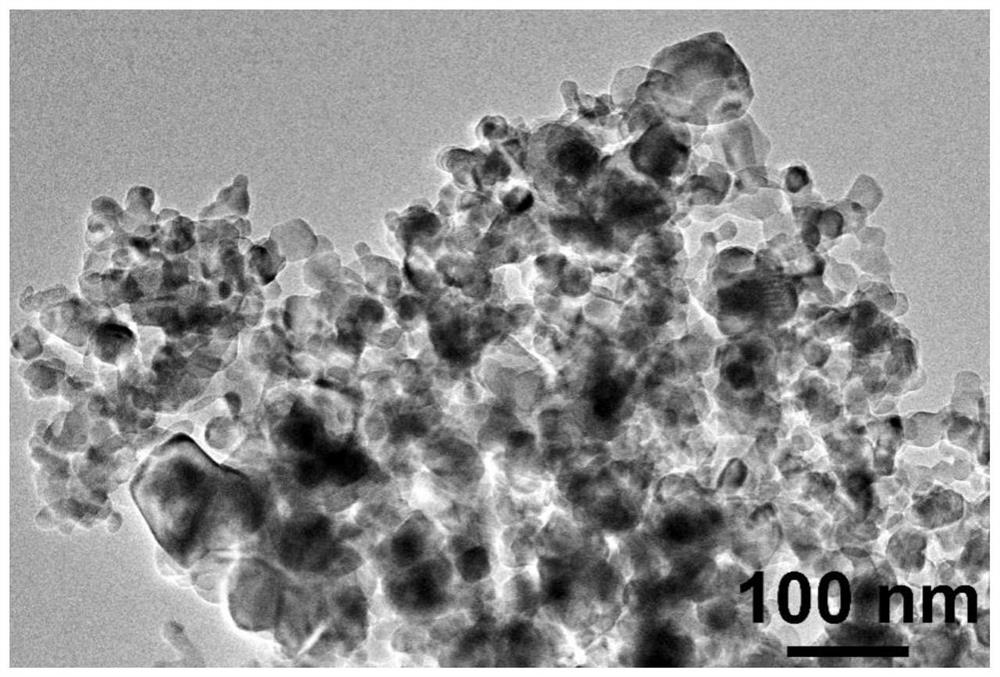

[0063] The phase, morphology, elemental composition of the obtained product measured under XRD, EDX, scanning electron microscope, and the stretching and bending pictures of the silica gel film taken under macroscopic conditions are as follows. Figures 5 to 8 shown. Figure 5 XRD analysis shows that the product consists of a large amount of anatase and a small amount of rutile-structured TiO 2 , body-centered cubic Fe and amorphous carbon composition. The elemental composition of the obtained product measured under EDX is as follows Image 6 As shown, the product is composed of Ti, Fe, O, C elements, the atomic percentage of Fe is 3.29%, and the atomic percentage of C is 9.91%. The morphology of the obtained product measured under the scanning electron microscope...

Embodiment 3

[0067] Compared with the preparation steps disclosed in Example 1, the only difference is that the mass of iron pentacarbonyl added is 0.75mL, and the other preparation steps and process parameters are the same.

[0068] The elemental composition of the obtained product measured under EDX is as follows Figure 9 shown. The product is composed of Ti, Fe, O, C elements, the atomic percentage of Fe is 6.14%, and the atomic percentage of C is 12.59%.

[0069] The heterogeneous material is filled in the base material with a mass fraction of 45%, and its reflectivity is measured as shown in Table 1. The effective bandwidth of the reflectivity less than or equal to -10dB is 9.2GHz, and the maximum reflection loss is -41.82dB; its thermal The conductivity is 1.520W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com