A light-weight thermal insulation material containing silica micropowder

A lightweight heat-insulating, silicon oxide-containing technology, applied in the field of refractory materials, can solve problems such as difficult control, environmental pollution, and large shrinkage line changes, and achieve the effects of extending service life, controlling thermal conductivity, and preventing cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

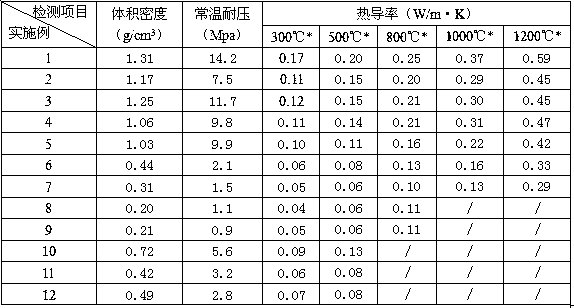

[0028] The composition and mass percentage of solid raw materials for lightweight heat insulation materials are 84% of silica micropowder, 4% of aluminum silicate fiber, 3% of aluminum powder, and 9% of solid aluminum dihydrogen phosphate. The solid raw materials and silicon Mix 50% of the sol and stir together, stir for 1 minute after the slurry appears, and then pour into shape. It needs to be cured for 1 day at a temperature of 15°C and a relative humidity of 40%, and finally dried at a temperature of 100°C to complete the production with a volume density of 1.31g / cm 3 Lightweight thermal insulation material containing silica micropowder. The performance indicators are shown in Table 1.

Embodiment 2

[0030] The composition and mass percentage of solid raw materials for lightweight heat insulation materials are 73% of silica micropowder, 24.9% of aluminum silicate fiber, 2% of aluminum powder, and 0.1% of solid aluminum dihydrogen phosphate. Sol 2% and water 40% are mixed and stirred together, and after the slurry appears, stir for 3 minutes before casting. It needs to be cured for 1 day at a temperature of 15°C and a relative humidity of 40%, and finally dried at a temperature of 100°C to complete the production with a volume density of 1.17g / cm 3 Lightweight thermal insulation material containing silica micropowder. The performance indicators are shown in Table 1.

Embodiment 3

[0032] The composition and mass percentage of solid raw materials for lightweight heat insulation materials are 77% of silica micropowder, 5% of aluminum silicate fiber, 15% of aluminum powder, and 3% of solid aluminum dihydrogen phosphate. The solid raw materials and silicon Sol 20% and water 25% are mixed and stirred together, and after the slurry appears, stir for 3 minutes before casting. It needs to be cured for 1 day at a temperature of 15°C and a relative humidity of 40%, and finally dried at a temperature of 100°C to complete the production with a volume density of 1.25g / cm 3 Lightweight thermal insulation material containing silica micropowder. The performance indicators are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com