A method for preparing low thermal conductivity thermal insulation material from high-calcium gasification ash slag

A technology of low thermal conductivity and thermal insulation materials, applied in chemical instruments and methods, other chemical processes, cement production, etc., can solve the problems of poor thermal insulation performance, low utilization rate of ash, and preparation of thermal insulation materials, etc. Achieve the effects of easy operation, environmental protection and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

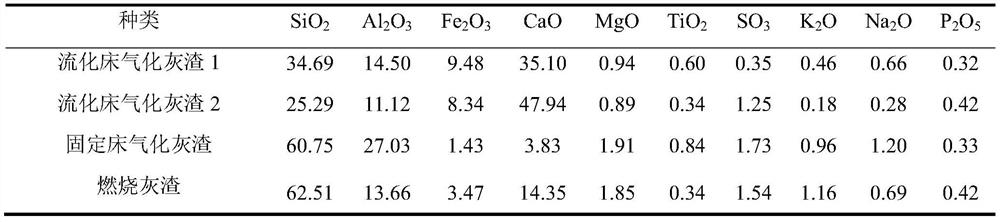

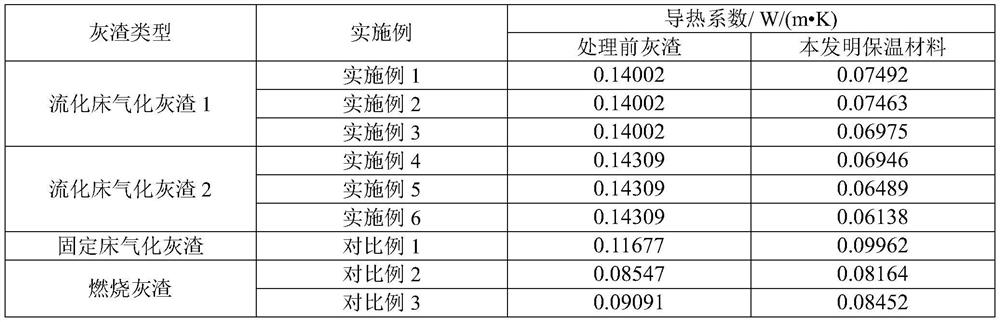

[0023] Grind the fluidized bed gasification ash 1 to a particle size of 300 mesh, calcine at 600°C for 3 hours, and then quench it, take 2M acetic acid, and mix the acetic acid solution with the calcined gasification ash according to the ratio of acetic acid solution:reaction raw material = 150ml:10g The residue was reacted at 90°C for 18 minutes, the filter residue was washed until neutral, dried in an oven, and ground to a particle size of 300 mesh to obtain a low thermal conductivity insulation material.

Embodiment 2

[0025] Grind the fluidized bed gasification ash 1 to a particle size of 300 mesh, calcine at 660°C for 2.5 hours, and then quench it, take 4M acetic acid, and mix the acetic acid solution with the calcined gasification After ultrasonication for 1 minute, the ash residue was reacted at 80°C for 120 minutes. The filter residue was washed until neutral, dried in an oven, and ground to a particle size of 300 mesh to obtain a low thermal conductivity insulation material.

Embodiment 3

[0027] Grind the fluidized bed gasification ash 1 to a particle size of 100 mesh, calcine at 700°C for 2 hours, and then quench it, take 6M acetic acid, and mix the acetic acid solution with the calcined gasification ash according to the ratio of acetic acid solution:reaction raw material = 110ml:10g The residue was ultrasonicated for 3 minutes and then reacted at 70°C for 90 minutes. The filter residue was washed until neutral, dried in an oven, and ground to a particle size of 100 mesh to obtain a low thermal conductivity insulation material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com