Preparation method of rare earth doped silicon dioxide aerogel

A silicon dioxide and rare earth doping technology, which is applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of low porosity, low pore size, increased thermal conductivity, and inapplicability of high-temperature heat insulation, etc., to improve the use of Temperature, high production efficiency, and favorable effects for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

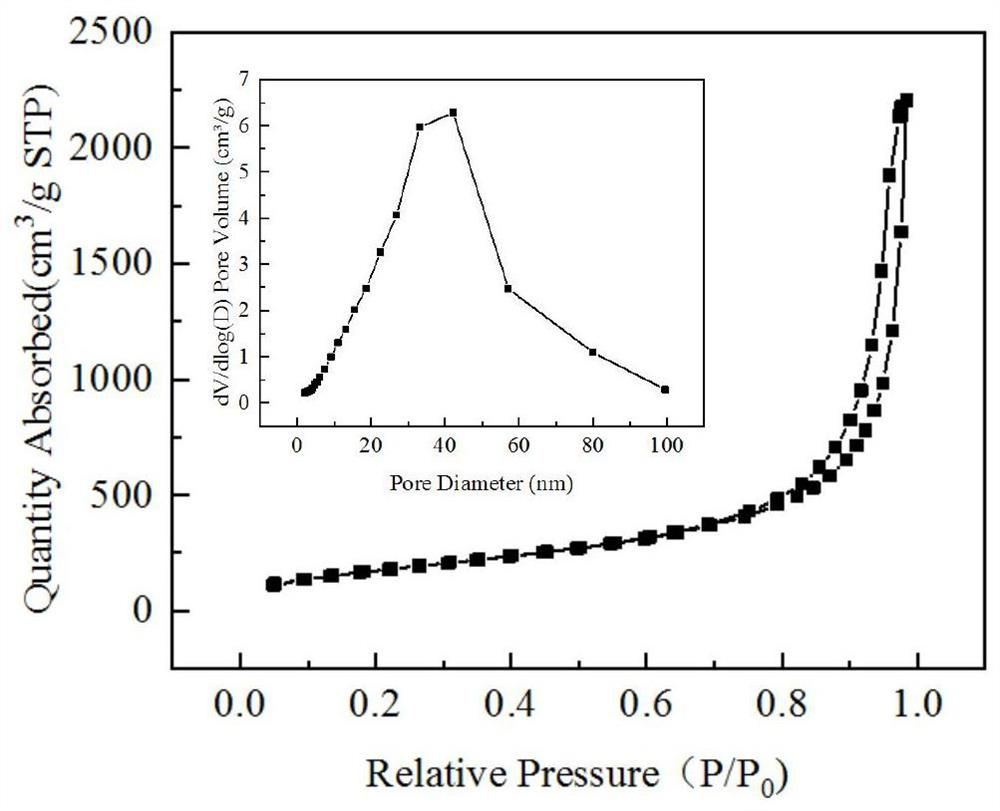

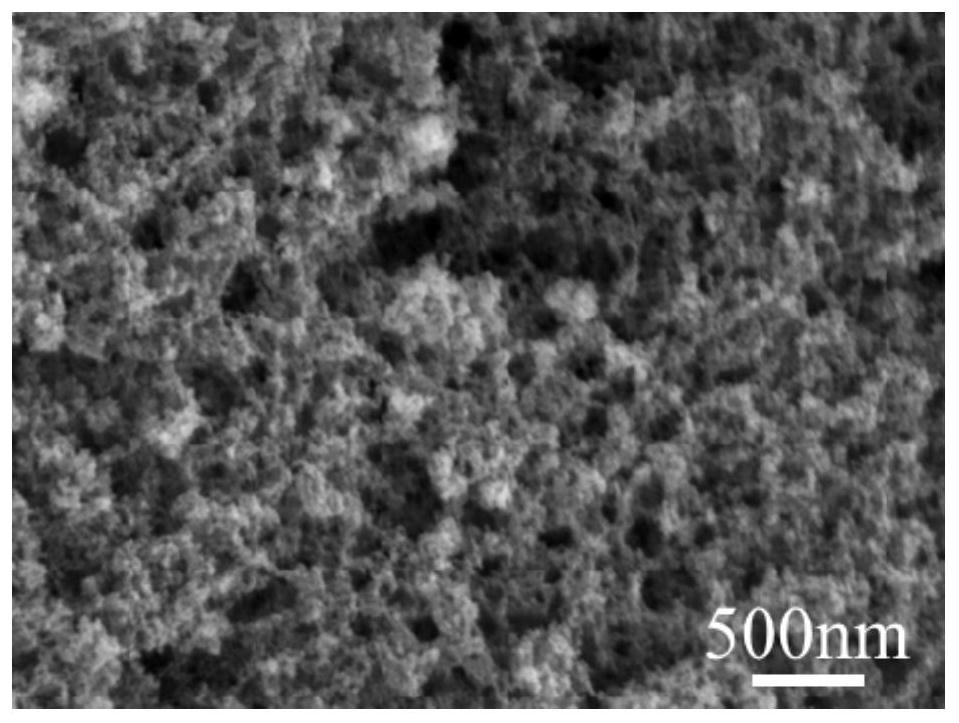

Image

Examples

Embodiment 1

[0020] This embodiment includes the following steps:

[0021] (1) Add 20.8g TEOS, 55.2g absolute ethanol and 5.4g H 2 0, mechanically stirred for 15min, and 3.65g mass fraction was added dropwise thereto through the constant pressure funnel as the diluent of hydrochloric acid ethanol of 0.05wt%, and after stirring for 120min, it was sealed and left standing at room temperature for 24h to obtain the molar ratio n(TEOS):n(C 2 h 5 OH): n(H 2 O)=1:12:3 SiO 2 Sol.

[0022] (2) 34.8g Y(NO 3 ) 3 4H 2 O powder was dissolved in 10.8g of water, heated at 50°C for 30min, and cooled to room temperature to obtain Y(NO 3 ) 3 solution.

[0023] (3) Weigh 0.684g of the material obtained in step (2), slowly drop into 9.31g of SiO 2 In the sol, stir magnetically for 30 min.

[0024] (4) Drop ammonia water and ethanol diluent into the material obtained in step (3), stir evenly, and let stand to gel.

[0025] (5) the above Y-SiO 2 The gel was airtight and aged for 24 hours before sup...

Embodiment 2

[0028] This embodiment includes the following steps:

[0029] (1) Add 20.8g TEOS, 32.2g absolute ethanol and 5.4g H 2 0, mechanically stirred for 15min, dripped 3.65g massfraction of 0.05wt% hydrochloric acid ethanol diluent therein with a speed of 6s / drops through a constant pressure funnel, sealed and stood still at room temperature for 24h after stirring for 120min, and obtained the molar ratio n(TEOS ):n(C 2 h 5 OH): n(H 2 O)=1:7:3 SiO 2 Sol.

[0030] (2) 34.8g Y(NO 3 ) 3 4H 2 O powder was dissolved in 10.8g of water, heated at 50°C for 30min, and cooled to room temperature to obtain Y(NO 3 ) 3 solution.

[0031] (3) Weigh 0.137g of the material obtained in step (2), slowly drop into 12.8g of SiO 2 In the sol, stir magnetically for 30 min.

[0032] (4) Drop ammonia water and ethanol diluent into the material obtained in step (3), stir evenly, and let stand to gel.

[0033] (5) the above Y-SiO 2 The gel was airtight and aged for 24 hours before supercritical d...

Embodiment 3

[0036] The preparation method of the present embodiment comprises the following steps:

[0037] (1) Add 20.8g TEOS, 92g absolute ethanol and 5.4g H 2 0, mechanically stirred for 15min, dripped 3.65g of hydrochloric acid ethanol diluent with a mass fraction of 0.05wt% through a constant pressure funnel at a speed of 6s / drop, stirred for 120min and then sealed at room temperature for 24h, so that the hydrolysis reaction was sufficient and slow Carried out to obtain the molar ratio n(TEOS):n(C 2 h 5 OH): n(H 2 O)=1:20:3 SiO 2 Sol.

[0038] (2) 34.8g Y(NO 3 ) 3 4H 2 O powder was dissolved in 10.8g of water, heated at 50°C for 30min, and cooled to room temperature to obtain Y(NO 3 ) 3 solution.

[0039] (3) Weigh 0.228g of the material obtained in step (2), slowly drop into 12.2g of SiO 2 In the sol, stir magnetically for 30 min.

[0040] (4) Drop ammonia water and ethanol diluent into the material obtained in step (3), stir evenly, and let stand to gel.

[0041] (5) t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com