Preparation method of polystyrene ultrafine powder by use of acryloyl chloride-phenethylene copolymer azide modified carbon nano tube as antistatic agent

A technology of styrene copolymer and nitriding acryloyl chloride is applied in the fields of thermal conductivity and antistatic, which can solve the problems of increasing defects and destroying the aspect ratio of carbon nanotubes, and achieves the effect of good antistatic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

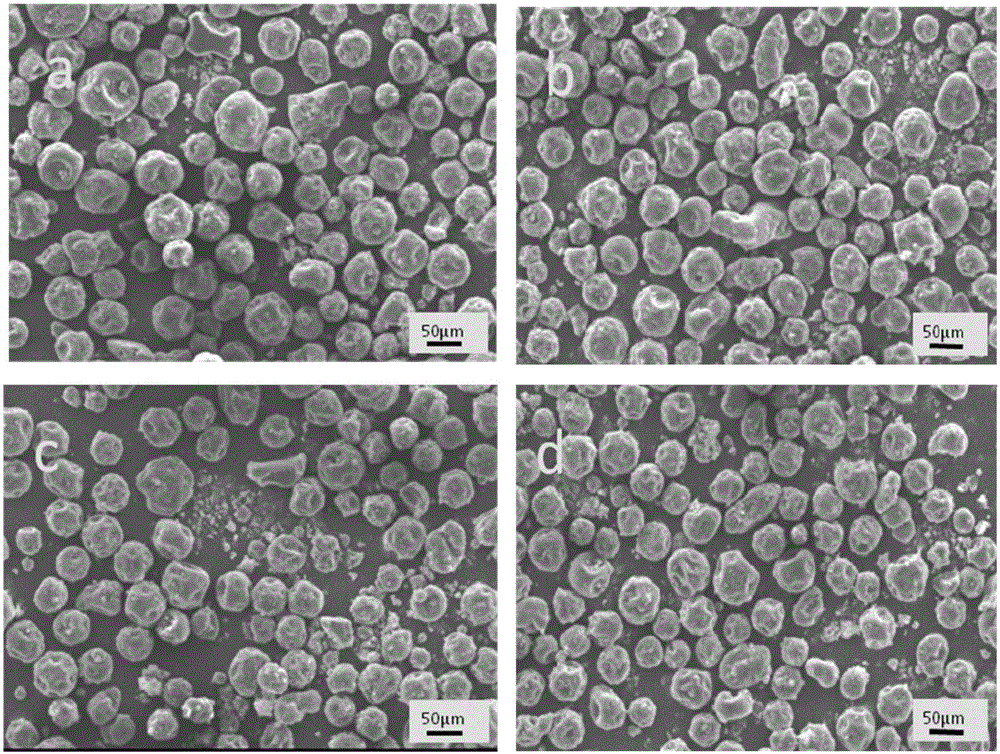

Image

Examples

Embodiment 1

[0023] (1) Preparation of acryloyl chloride-styrene copolymer: Weigh 250 mg of AIBN, 27 mL of 1,4-dioxane and 12.5 mL of styrene into a dry polymerization bottle, then inject 1 mL of acryloyl chloride with a syringe, and stir magnetically at room temperature After 10 minutes, the temperature was raised to 60° C. and stirred for 24 hours to obtain a light yellow solution of acryloyl chloride-styrene copolymer.

[0024] (2) Preparation of azide acryloyl chloride-styrene copolymer: Dissolve 2.5 g of the acryloyl chloride-styrene copolymer obtained by the reaction in step (1) in 16 mL of acetone, and then add 2.5 mL of 10% azide by mass fraction. Aqueous sodium nitride solution is added dropwise, and the reaction is carried out in an ice bath for 5 hours. After the reaction is completed, acetone, water and sodium chloride are removed to obtain a copolymer of azide acryloyl chloride-styrene.

[0025] (3) Grafting modification of carbon nanotubes: 23 mg of multi-walled carbon nanotu...

Embodiment 2

[0028] (1) Preparation of acryloyl chloride-styrene copolymer: Weigh 250 mg of AIBN, 27 mL of 1,4-dioxane and 12.5 mL of styrene into a dry polymerization bottle, then inject 1 mL of acryloyl chloride with a syringe, and stir magnetically at room temperature After 10 minutes, the temperature was raised to 60° C. and stirred for 24 hours to obtain a light yellow solution of acryloyl chloride-styrene copolymer.

[0029] (2) Preparation of azide acryloyl chloride-styrene copolymer: Dissolve 2.5 g of the acryloyl chloride-styrene copolymer obtained by the reaction in step (1) in 16 mL of acetone, and then add 2.5 mL of 10% azide by mass fraction. Aqueous sodium nitride solution is added dropwise, and the reaction is carried out in an ice bath for 5 hours. After the reaction is completed, acetone, water and sodium chloride are removed to obtain a copolymer of azide acryloyl chloride-styrene.

[0030] (3) Grafting modification of carbon nanotubes: 23 mg of multi-walled carbon nanotu...

Embodiment 3

[0033] (1) Preparation of acryloyl chloride-styrene copolymer: Weigh 250 mg of AIBN, 27 mL of 1,4-dioxane and 12.5 mL of styrene into a dry polymerization bottle, then inject 1 mL of acryloyl chloride with a syringe, and stir magnetically at room temperature After 10 minutes, the temperature was raised to 60° C. and stirred for 24 hours to obtain a light yellow solution of acryloyl chloride-styrene copolymer.

[0034] (2) Preparation of azide acryloyl chloride-styrene copolymer: Dissolve 2.5 g of the acryloyl chloride-styrene copolymer obtained by the reaction in step (1) in 16 mL of acetone, and then add 2.5 mL of 10% azide by mass fraction. Aqueous sodium nitride solution is added dropwise, and the reaction is carried out in an ice bath for 5 hours. After the reaction is completed, acetone, water and sodium chloride are removed to obtain a copolymer of azide acryloyl chloride-styrene.

[0035] (3) Grafting modification of carbon nanotubes: 23 mg of multi-walled carbon nanotube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com