Preparation method of boron nitride/carbon nanotube/polyimide composite material

A carbon nanotube and composite material technology is applied in the field of preparation of boron nitride/carbon nanotube/polyimide composite materials, which can solve the problems of poor thermal conductivity and increased electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

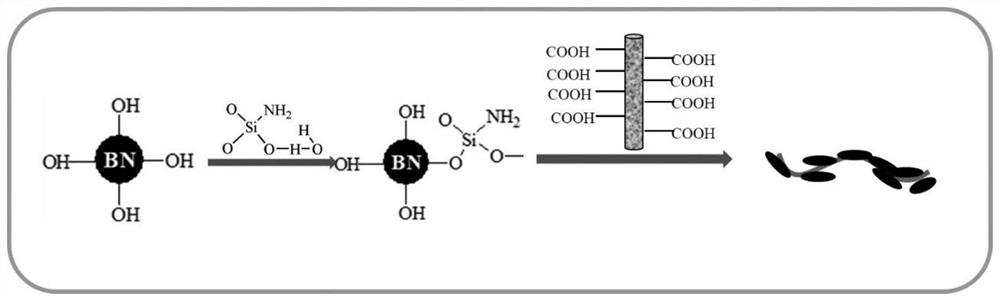

[0017] (1) Disperse commercially available micron boron nitride in 5mol / L sodium hydroxide solution to make a 4g / L dispersion, place it in an ultrasonic bath with an oscillation frequency of 26kHz and an output power of 500W for 2h, then Transfer the dispersion to a hydrothermal kettle and react at 150°C for 6h. After the reaction is complete, cool the room temperature naturally, wash the product with deionized water until it is neutral, and dry it in a vacuum oven at 60°C for 8h to obtain boron nitride nanoparticles. piece;

[0018] (2) Add the silane coupling agent KH550 into 95% ethanol aqueous solution to form a 0.5wt% solution, then add the boron nitride nanosheets obtained in step (1), stir and react at 60°C for 8h, and spin the solvent to obtain silane Coupling agent modified boron nitride, wherein the mass ratio of silane coupling agent to boron nitride is 1:10;

[0019] (3) Add 1 g of commercially available carbon nanotubes to a mixture of 30 mL of concentrated hydro...

Embodiment 2

[0024] (1) consistent with embodiment 1 step (1);

[0025] (2) Add the silane coupling agent KH550 into 95% ethanol aqueous solution to form a 0.5wt% solution, then add the boron nitride nanosheets obtained in step (1), stir and react at 60°C for 8h, and spin the solvent to obtain silane Coupling agent modified boron nitride, wherein the mass ratio of silane coupling agent to boron nitride is 1:20;

[0026] (3) consistent with embodiment 1 step (3);

[0027] (4) consistent with embodiment 1 step (4);

[0028] (5) consistent with embodiment 1 step (5);

[0029] (6) Consistent with embodiment 1 step (6), the thermal conductivity of the composite material reaches 0.7W / mK, and the resistance is 1.5×10 11 Ωm.

Embodiment 3

[0031] (1) consistent with embodiment 1 step (1);

[0032] (2) consistent with embodiment 1 step (2);

[0033] (3) consistent with embodiment 1 step (3);

[0034] (4) Add 0.1g of carboxyl carbon nanotubes and 1g of modified boron nitride to 100g of N,N-dimethylacetamide, at room temperature, in an ultrasonic bath with an oscillation frequency of 26kHz and an output power of 500W Ultrasound for 2 hours to obtain boron nitride / carbon nanotube filler;

[0035] (5) consistent with embodiment 1 step (5);

[0036] (6) Consistent with embodiment 1 step (6), the thermal conductivity of the composite material reaches 0.7W / mK, and the resistance is 1.8×10 11 Ωm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com