Graphite-silicone rubber composite material and preparation method thereof

A composite material and silicone rubber technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the impact of thermal conductivity and performance, metal does not have softness and compressibility, low thermal conductivity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

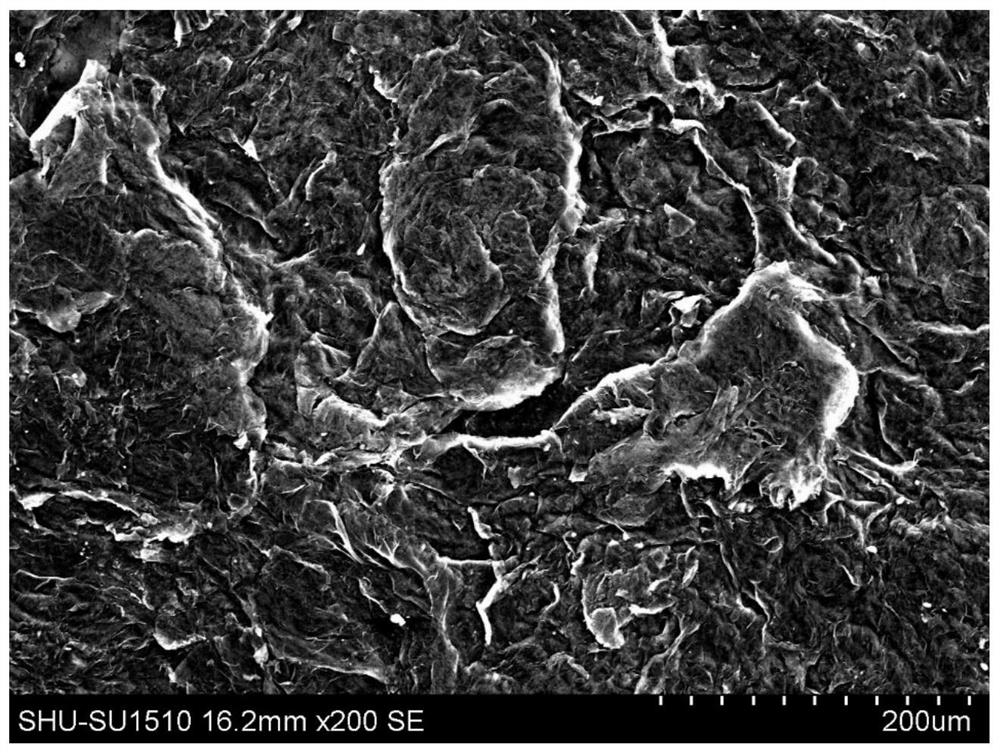

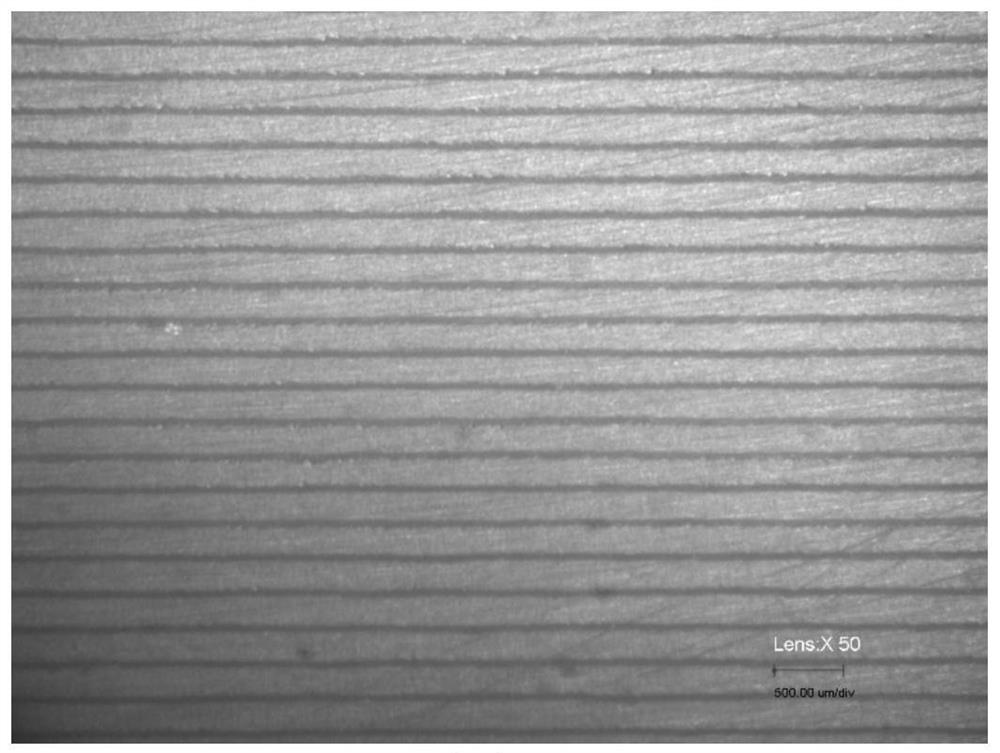

Image

Examples

Embodiment Construction

[0035] Below in conjunction with specific embodiment above-mentioned scheme is described further, preferred embodiment of the present invention is described in detail as follows:

[0036] In the present embodiment, a preparation method of graphite-silicone rubber composite material is provided, comprising the steps of:

[0037] a. Use graphite paper with a purity greater than 99.99% and a thickness of 0.2-0.5mm as the base material.

[0038] b. Place the substrate in alkaline degreasing water at 55°C for ultrasonic vibration for more than 30 minutes, and rinse and clean it with distilled water several times after completion;

[0039] c. Use absolute ethanol as a solvent to prepare a KH-550 solution with a mass fraction of 5-10% for surface modification of the substrate;

[0040] d. Soak the rinsed graphite paper in the KH-550 solution in step c for more than 60 minutes, then take it out, and dry it in a hot air box above 80°C for more than 60 minutes;

[0041] E. place a lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com