Adjustment method of thin-wall numerical-controlled bend-pipe forming die

A technology for forming molds and debugging methods, applied in the field of machining, can solve problems such as difficult control, excessive wall thickness reduction, instability and wrinkling, etc., and achieve the effect of reducing production costs and reducing the number of mold adjustments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

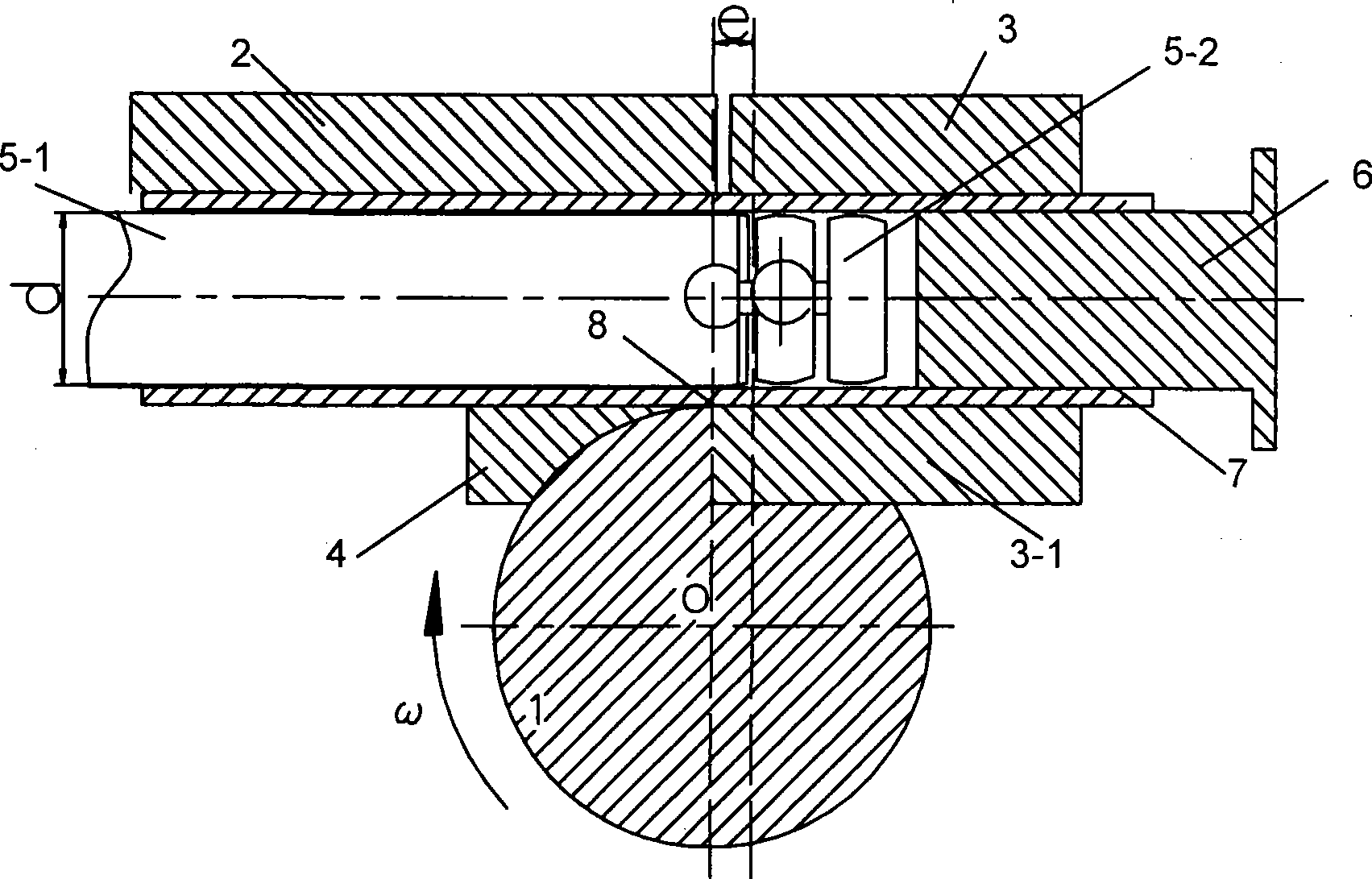

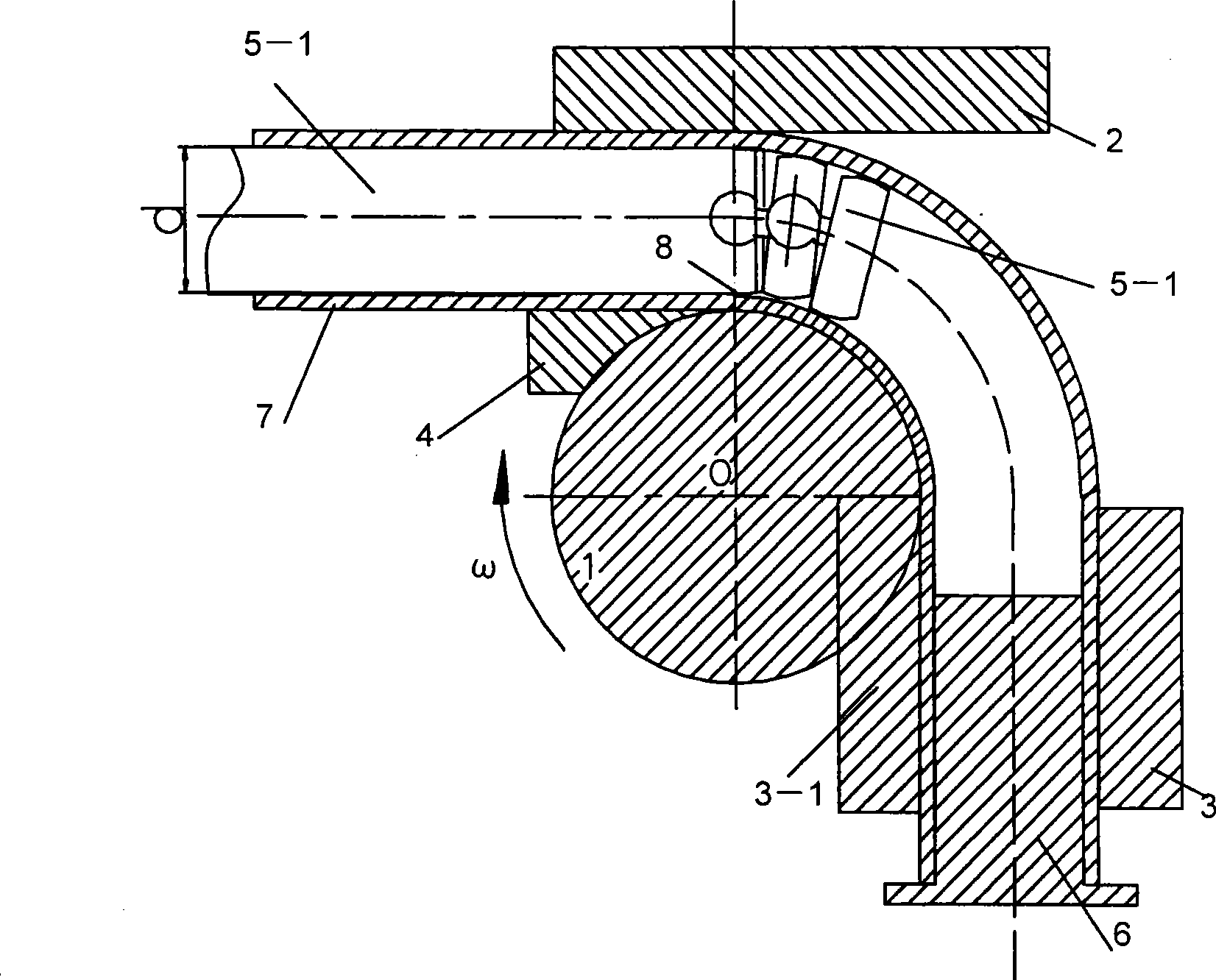

[0028] A mold adjusting method disclosed by the present invention has been successfully applied to the numerical control bending forming of aluminum alloy and stainless steel thin-walled tubes with small bending radius, and the bending specifications are 38×1×57 (outer diameter of pipe material×wall thickness×bending radius of center line) ), 50×1×75 and 50×1×100, etc. Taking the mold debugging of the bending process of aluminum alloy pipes with a bending specification of 38×1×57 as an example, the applicability of the present invention to the forming of thin-walled numerically controlled pipe bends is illustrated. The bending speed is 0.8 rad / s.

[0029] Determine the mold adjustment sequence as follows: bending die installation -> initial installation of clamping blocks and pressing blocks -> core mold installation -> anti-wrinkle block installation -> height adjustment of pressing blocks and clamping blocks -> apply lubrication (including pipe / anti-wrinkle block , pipe / c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com