Method for quickly adjusting servo dynamic parameters of five-axis linkage numerically controlled milling machine

A CNC milling machine and rapid adjustment technology, which is used in automatic control devices, metal processing mechanical parts, metal processing and other directions, can solve the problems of high trial cutting cost, blindness of machine tool parameter adjustment, and unpredictable impact on parts processing accuracy. , to achieve the effect of good precision control and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

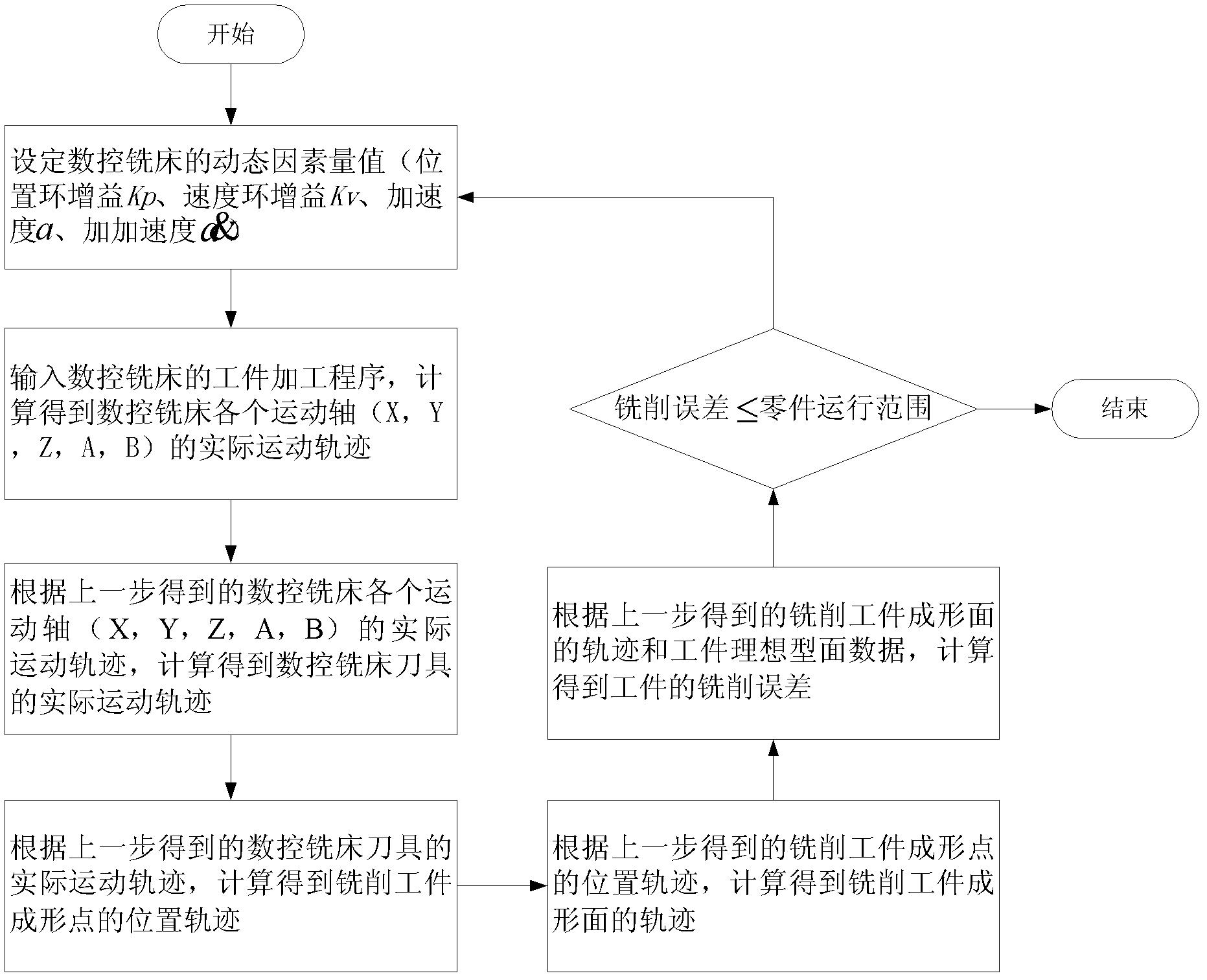

[0022] Attached below figure 1 Describe in detail the specific implementation process of the present invention with specific embodiments The method for quickly adjusting the servo dynamic parameters of a five-axis linkage CNC milling machine includes the following steps:

[0023] Step 1: Set the dynamic factor value of CNC milling machine (position loop gain Kp, speed loop gain Kv, speed a, jerk ), input the workpiece processing program of the CNC milling machine, and calculate the actual motion trajectory of each movement axis (X, Y, Z, A, B) of the CNC milling machine;

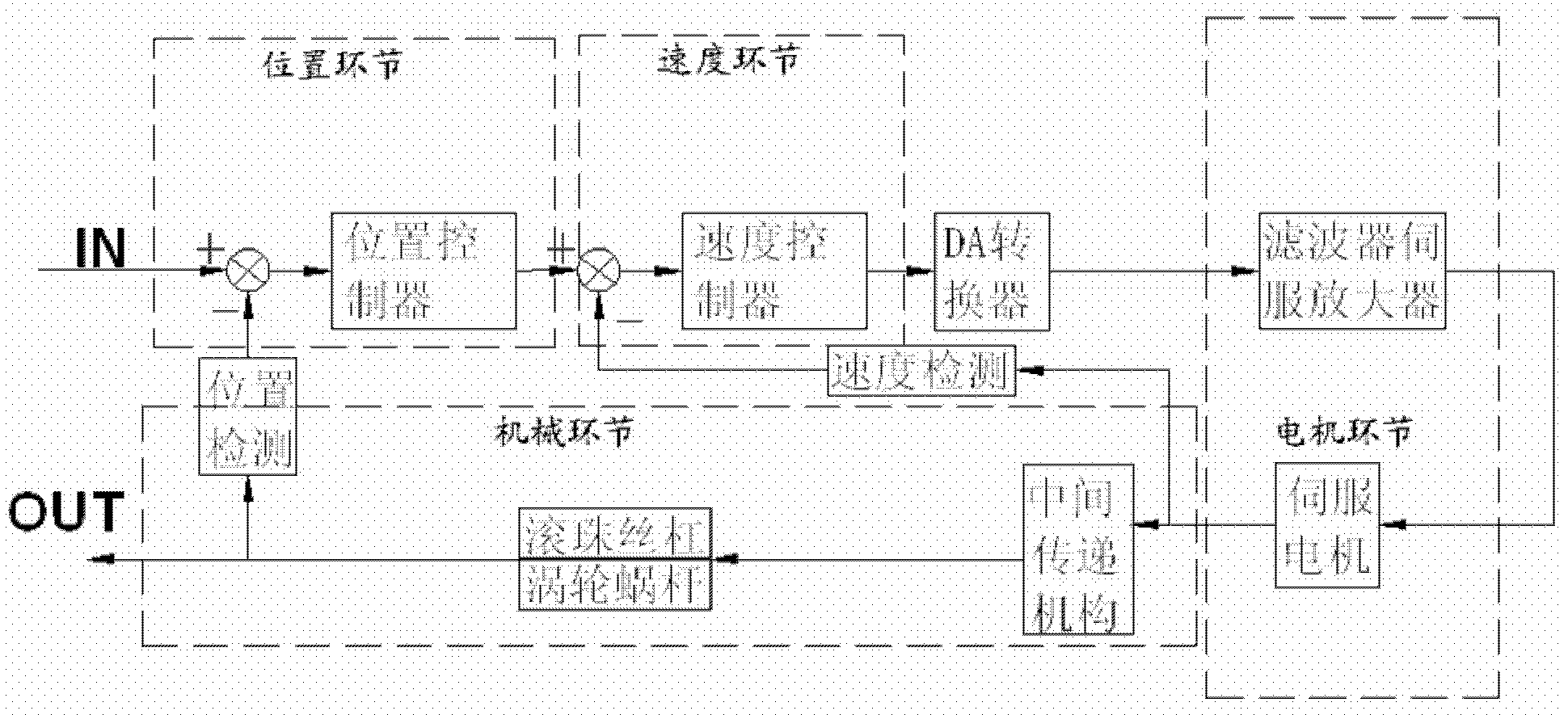

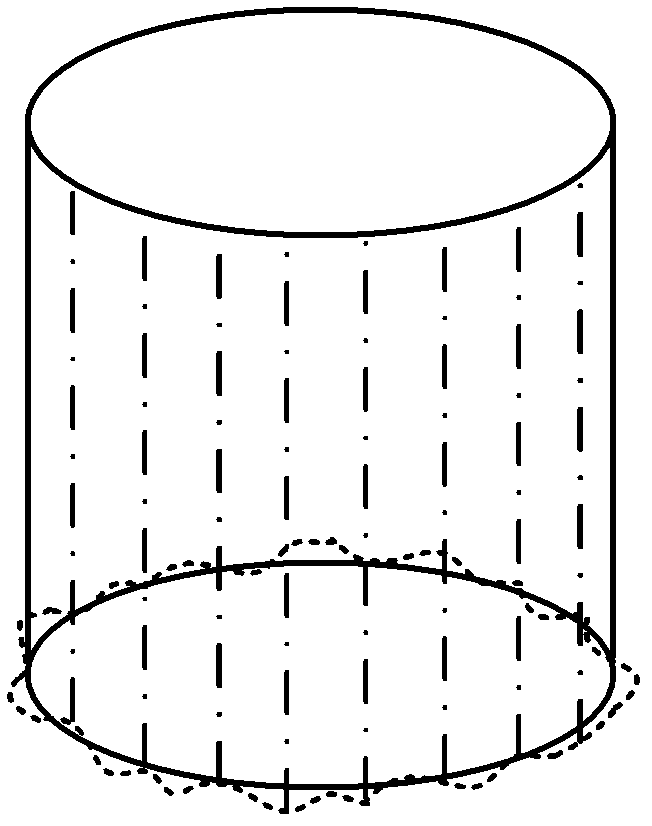

[0024] The motion axis of CNC milling machine can be expressed as the linear axis in the three directions of X, Y, and Z and the rotation axis in the three directions of A, B, and C. A, B, and C represent the rotation around the X, Y, and Z linear axes respectively. Axis, five-axis CNC milling machine includes X, Y, Z linear axis in three directions and any two of A, B, C three rotation axes, in this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com