Misaligned spline vibration wear contrast experimental device

A comparative experiment, vibration and wear technology, applied in the field of aerospace vibration, can solve the problems of lack of spline research experiment equipment, etc., and achieve the effect of stable work, convenient disassembly and assembly, and many experimental functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

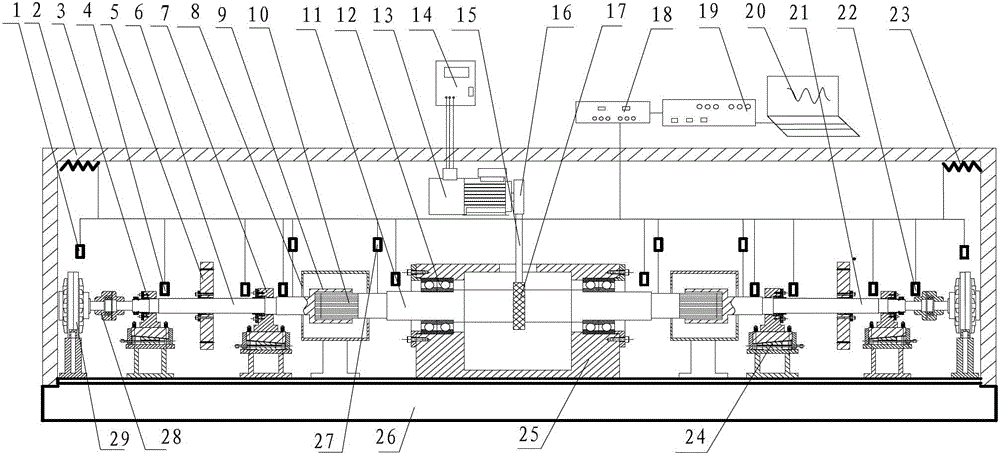

[0025] figure 2 It is a structural schematic diagram of the misaligned spline vibration and wear comparison experimenter of the present invention. As shown in the figure, the misaligned spline vibration and wear comparison tester of the present invention consists of a temperature sensor 1, a constant temperature cover 2, a ball bearing 3, a vibration displacement sensor 4, a wheel disc 5, a rotor 6, a bearing seat 7, and a grease collector. Cover 8, spline jacket 9, spline 10, rotor two 11, double row bearing 12, motor 13, frequency converter 14, synchronous belt 15, synchronous wheel 16, driven wheel 17, preamplifier 18, signal acquisition instrument 19, Industrial computer 20, rotor three 21, speed sensor 22, heating wire 23, bearing elevation adjustment device 24, integrated bearing seat 25, foundation platform 26, infrared thermometer 27, flexible coupling 28, magnetic powder brake 29.

[0026] (1) Design and process each part of the experimental device according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com