Pneumatic artificial muscles

A pneumatic artificial muscle and stomata technology, applied in the field of pneumatic artificial muscle, can solve the problems of difficult application in industrial environment, difficult standardized production, etc., and achieve the effects of compact structure, low price, and large output force/self-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

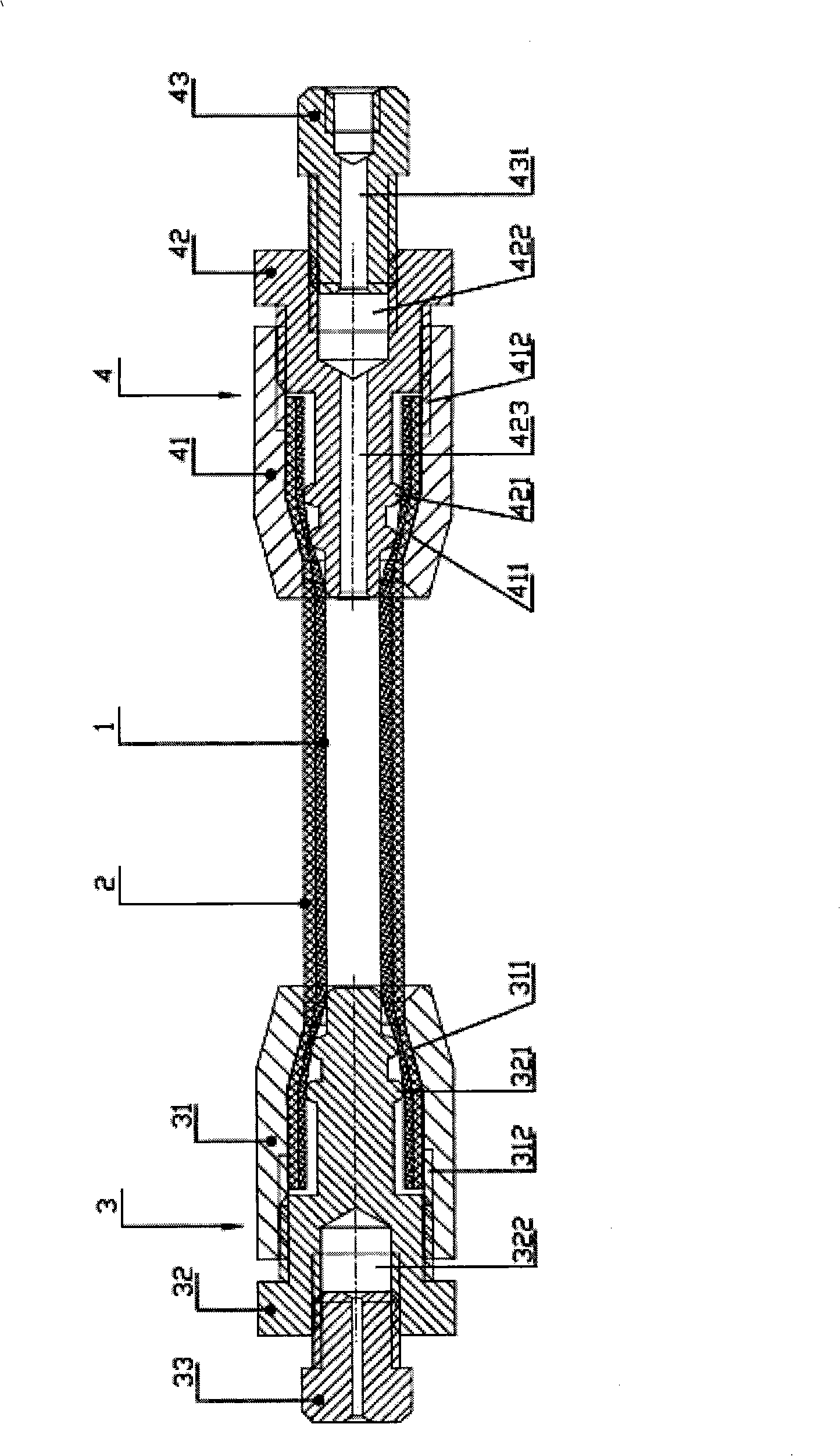

[0022] Depend on figure 1 Shown, the present invention is mainly made up of outer layer braided mesh sleeve 1, inner layer expansion tube 2, sealing assembly 3 and sealing assembly 4 with ventilation hole, wherein: outer layer braided mesh casing 1 is made of inelastic fiber in the form of cross spiral Winding; the outer braided mesh 1 can expand or contract radially under the action of external force; the outer braided mesh 1 is set outside the inner layer expansion tube 2, the original length of the outer braided mesh is 210mm, and the inner layer expands The original length of the tube 2 is 150mm. When installing, the two ends of the outer braided mesh 1 and the inner expansion tube 2 are aligned, and one end is inserted into the sealing assembly 3, and the other end is inserted into the sealing assembly 4 with air holes. The sealing plug 32 and the air hole The annular protrusions 321, 421 on the sealing plug 42 are pressed on the inner wall taper surfaces 311, 411 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com