Magnetic suspension type ultra-low-frequency vibration sensor

A vibration sensor, ultra-low frequency technology, applied in the field of magnetic levitation ultra-low frequency vibration sensor, can solve the problems that cannot be widely used in the industrial field, poor stability and reliability, bulky sensor, etc., to achieve multi-directional torsional vibration parameter measurement, The effect of wide measurement range and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

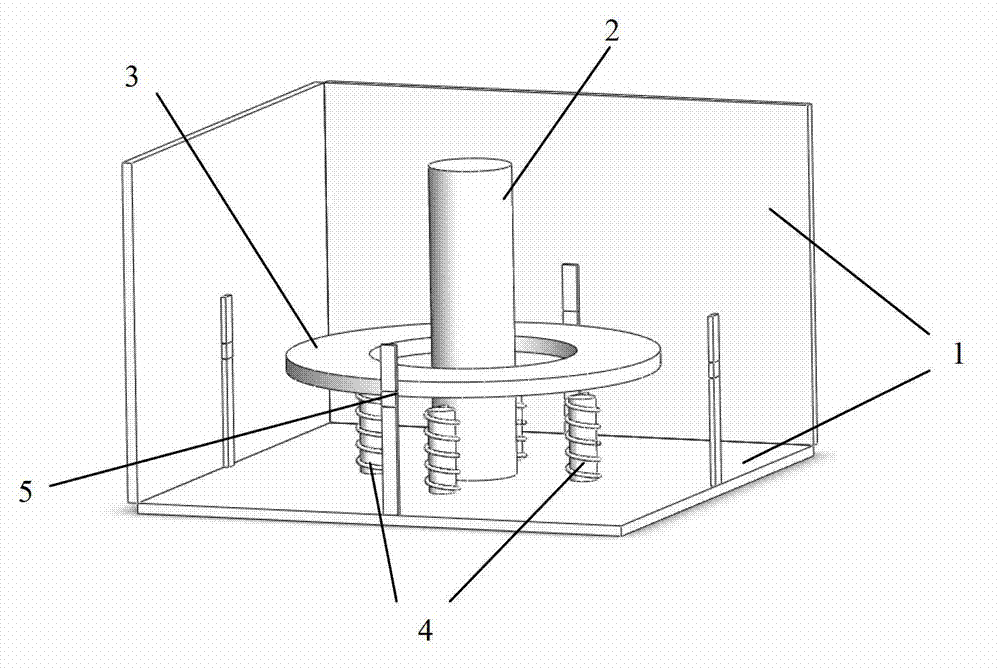

[0021] A magnetic levitation ultra-low frequency vibration sensor of the present invention comprises a housing, a cylindrical permanent magnet, a circular permanent magnet, an electromagnetic coil and a photoelectric displacement detector. Both the lower end of the cylindrical permanent magnet and the lower end of the electromagnetic coil are fixedly connected to the bottom of the housing, the upper end of the cylindrical permanent magnet is an S pole, and the lower end is an N pole. The annular permanent magnet is equivalent to the mass block in the system, the inner ring is N pole, the outer ring is S pole, the annular permanent magnet is concentric with the cylindrical permanent magnet, the inner ring of the annular permanent magnet and the lower pole of the cylindrical permanent magnet The magnetic fields of the halves repel each other, mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com