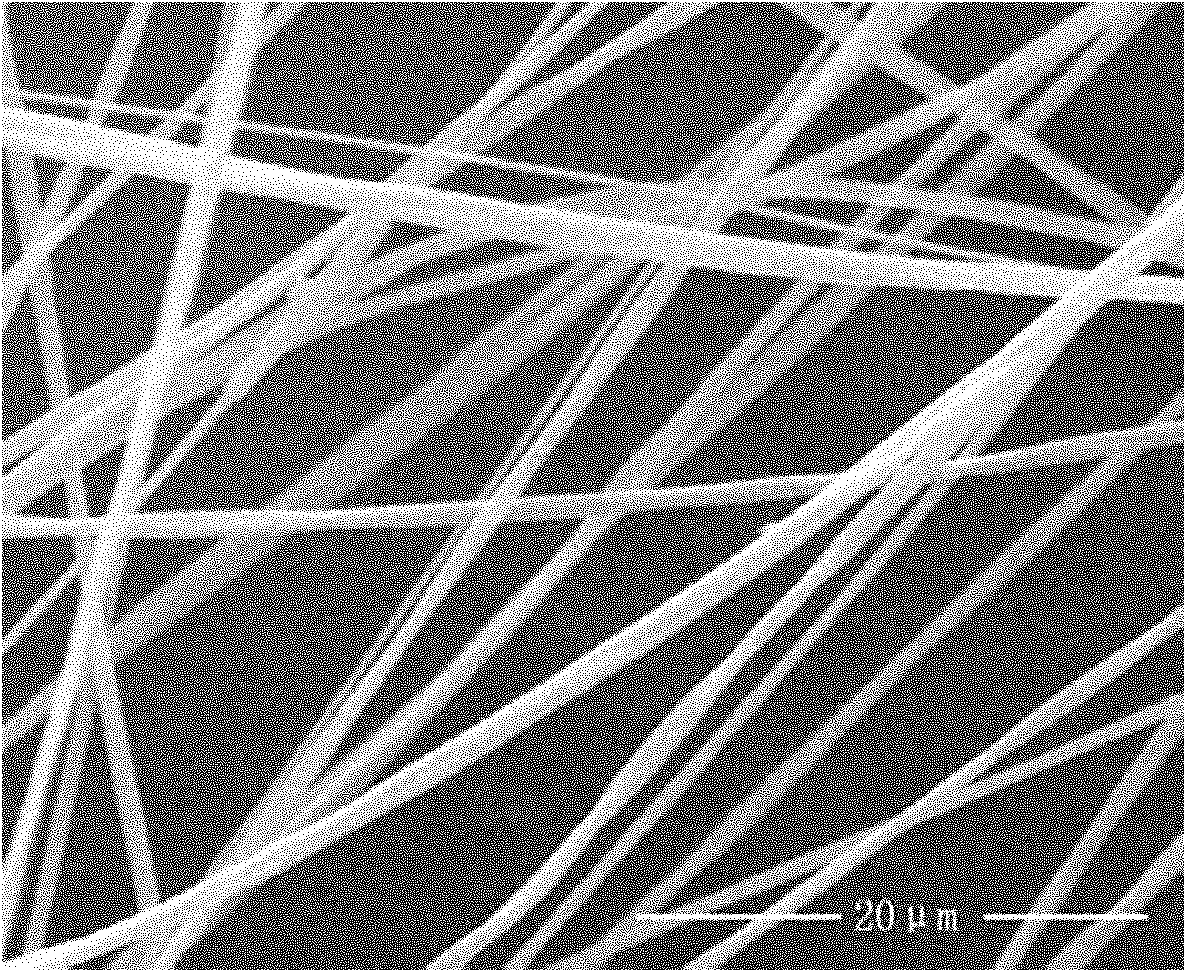

Preparation method of doping type fluorescent micron-nano fibers

A micro-nano-fiber, doping-type technology, applied in fiber processing, spinning solution preparation, fiber chemical characteristics, etc., can solve problems such as complex methods and large diameter of organic fluorescent fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

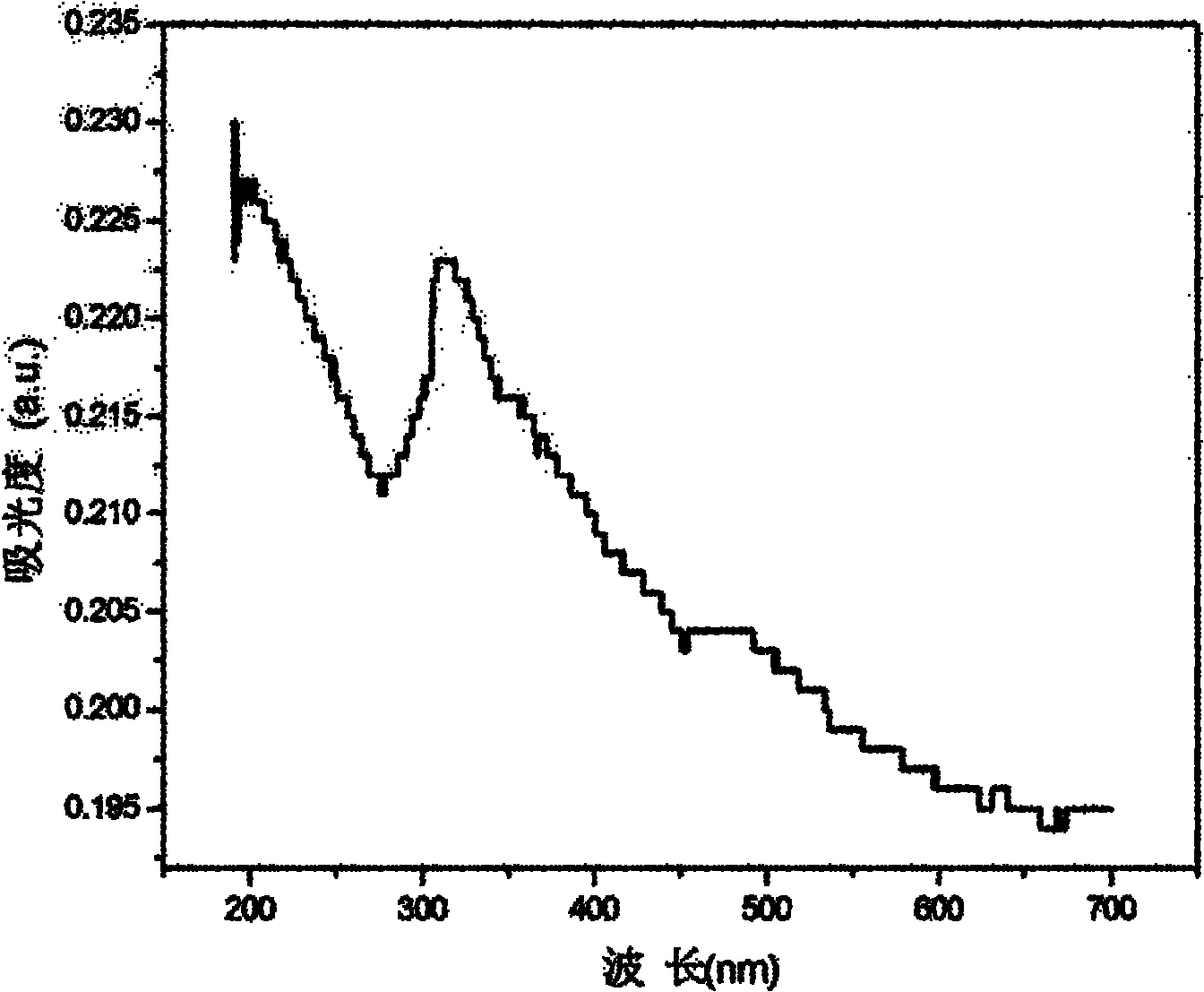

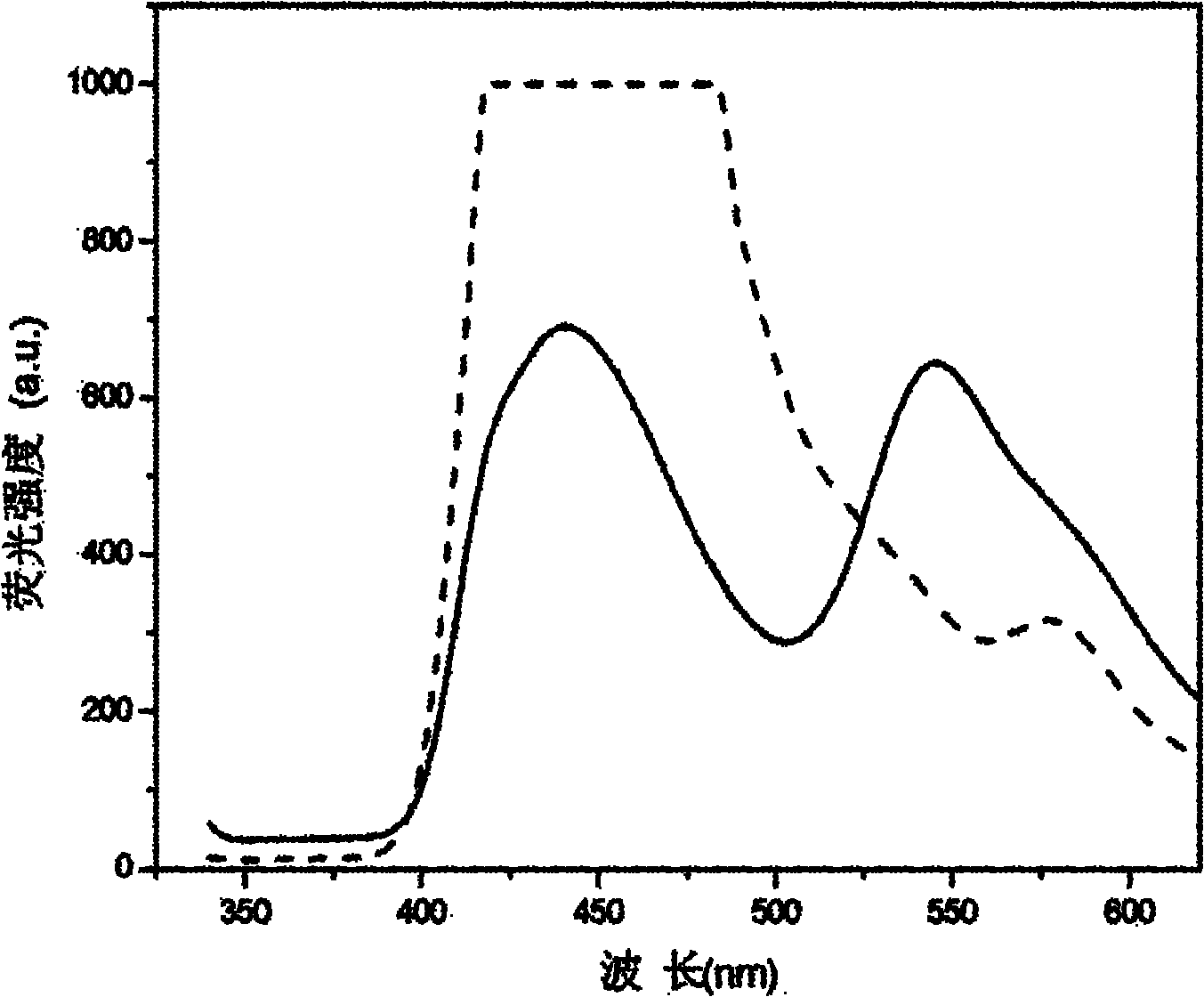

specific Embodiment approach 1

[0012] Embodiment 1: The preparation method of the doped fluorescent micro-nano fiber of this embodiment is carried out according to the following steps: 1. According to the ratio of adding 10 mL to 15 mL of organic solvent to 1 g of polymer, weigh the polymer and organic solvent, and polymerize The compound is added into an organic solvent, and after dissolving, a polymer solution is obtained, wherein the polymer is one or a combination of polystyrene, polymethyl methacrylate, polycarbonate and polyacrylonitrile, and the organic solvent One or a combination of chloroform, N, N-dimethylformamide, N, N-dimethylacetamide, benzene, toluene, chlorobenzene, dichloroethane and tetrahydrofuran; two , take by weighing dialdehyde triphenylamine and poly[ 2-methoxy-5 (2'-ethylhexyloxy) p-phenylene vinylene], and added to the polymer solution prepared in step 1, stirred for 6h to 12h to obtain spinning solution, in which dialdehyde three The mass volume ratio of aniline and polymer solu...

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment is different from Embodiment 1 in that: in step 1, 11 mL to 14 mL of organic solvent is added to 1 g of polymer. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that 13 mL of organic solvent is added to 1 g of polymer in Step 1. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com