Manufacturing process of 0.68 mm nonmagnetic alloy balls

A non-magnetic alloy and manufacturing process technology, applied in the field of 0.68mm non-magnetic alloy ball manufacturing process, can solve the problems of unsatisfactory finished product quality, high unqualified rate, poisonous beryllium bronze, etc., to prevent the generation of unqualified products and ensure stability And the effect of stable efficiency and quality level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

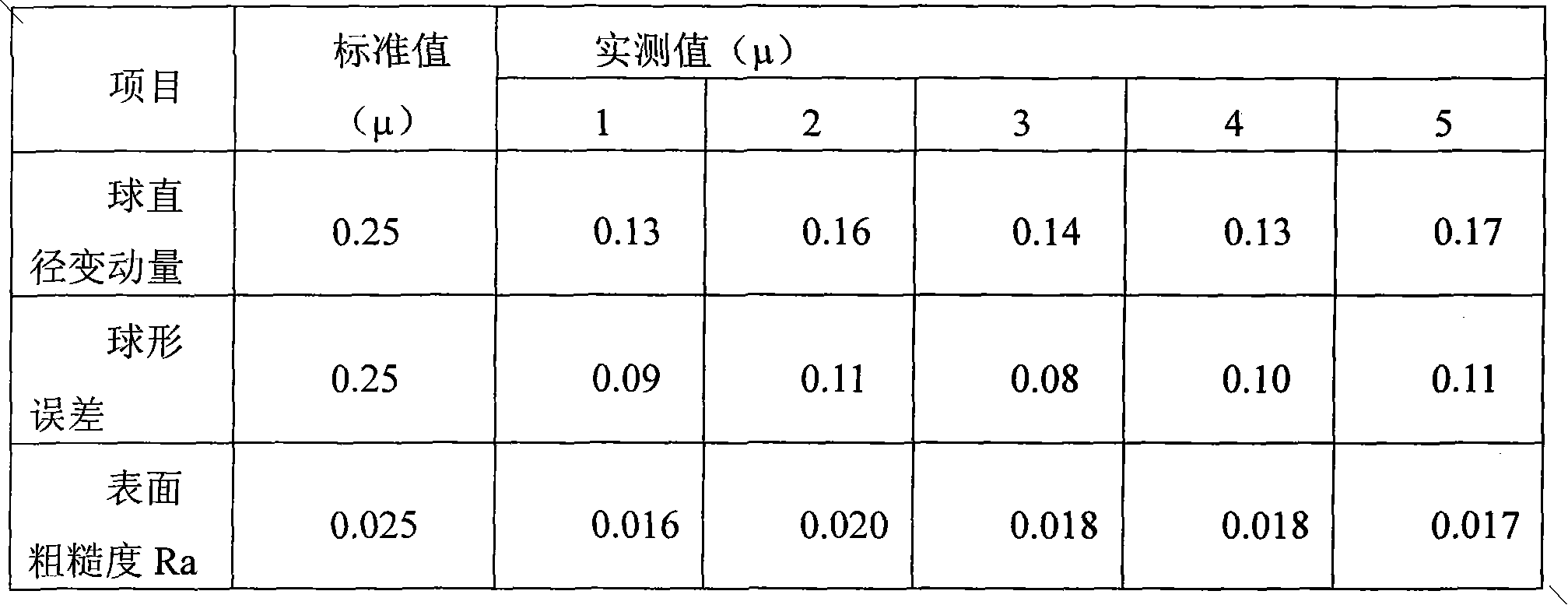

Image

Examples

Embodiment Construction

[0028] The manufacturing process of the 0.68mm non-magnetic alloy ball of the present invention will be further described below.

[0029] The 0.68mm non-magnetic alloy ball manufacturing process of the present invention comprises the following steps:

[0030] 1) Raw material inspection: According to the chemical composition, chemical analysis is carried out on the material, and the surface quality of the material is inspected to remove the bad parts;

[0031] 2) Cutting material: Use a medium-speed cold heading machine to cut material. Due to its good toughness, if the knife is blunt, it is very easy to have cutting burrs. Dressing tool, the cutting length is 1.05D;

[0032] 3) Light ball: This process uses XX-016 light ball machine to rotate and extrude at high speed between two high-hardness CRMoCu alloy cast iron plates with a diameter of 680mm, and through surface fatigue cutting, the steel wire cylinder section is gradually formed. round process. Since the delivery sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com