Process for manufacturing large high-chromium medium-carbon alloy forging back-up rolls

A manufacturing process, carbon alloy technology, applied in the field of high-chromium carbon alloy large-scale forged backup roll manufacturing process, can solve the problems of limited service life of the roll, affecting the depth of surface hardening, and long online service life, so as to reduce roll consumption, The effect of saving production cost and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

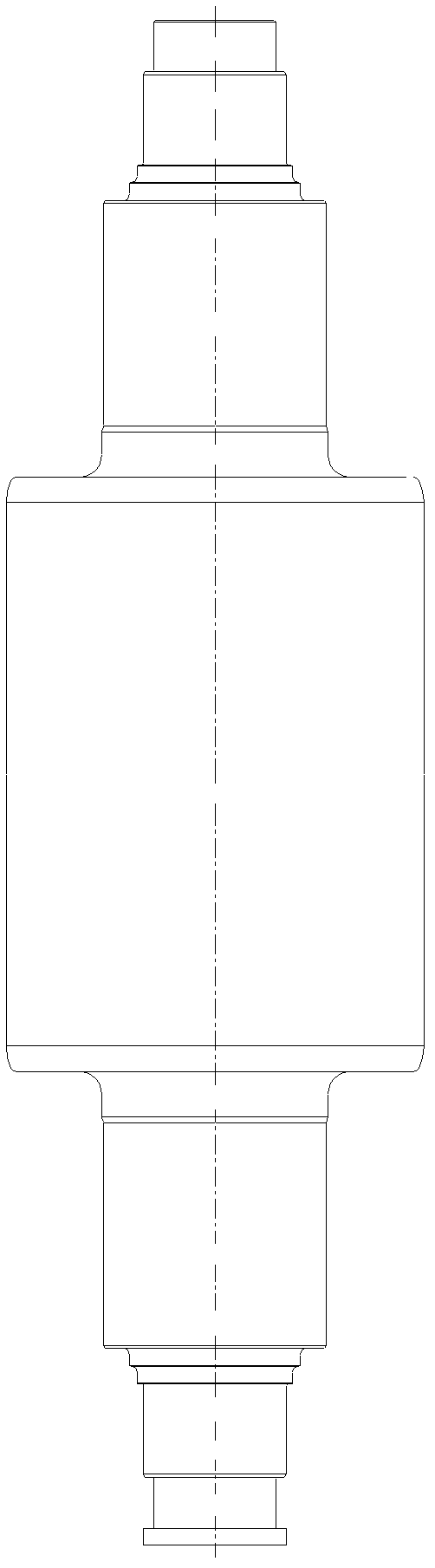

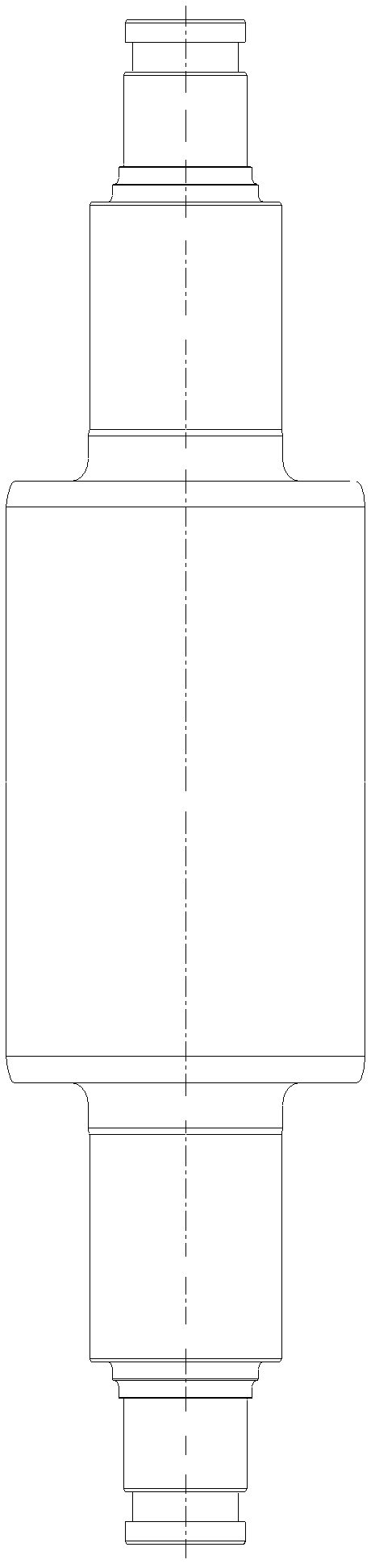

[0016] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0017] The manufacturing process of high-chromium medium-carbon alloy large-scale forging support roll is as follows: a. The alloy steel is smelted and then forged blank, wherein the medium-alloy steel includes the following components: by weight percentage: carbon content is 0.45-0.55%, silicon The content of manganese is 0.35-0.55%, the content of manganese is 0.25-0.50%, the content of chromium is 4.90-5.50%, the content of nickel is 0.40-0.60%, the content of molybdenum is 0.30-0.50%, the content of vanadium is 0.15-0.25%, phosphorus The content of sulfur is ≤0.020%, and the content of sulfur is ≤0.015%; b. Anneal the forged blank; c. Inspect the annealed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com