Mid-infrared anhydrous tellurate glass and preparation method thereof

A tellurite glass, infrared technology, applied in the field of glass and its preparation, can solve the problems of difficult optical fiberization, easy to be corroded by moisture, low thermal damage threshold, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

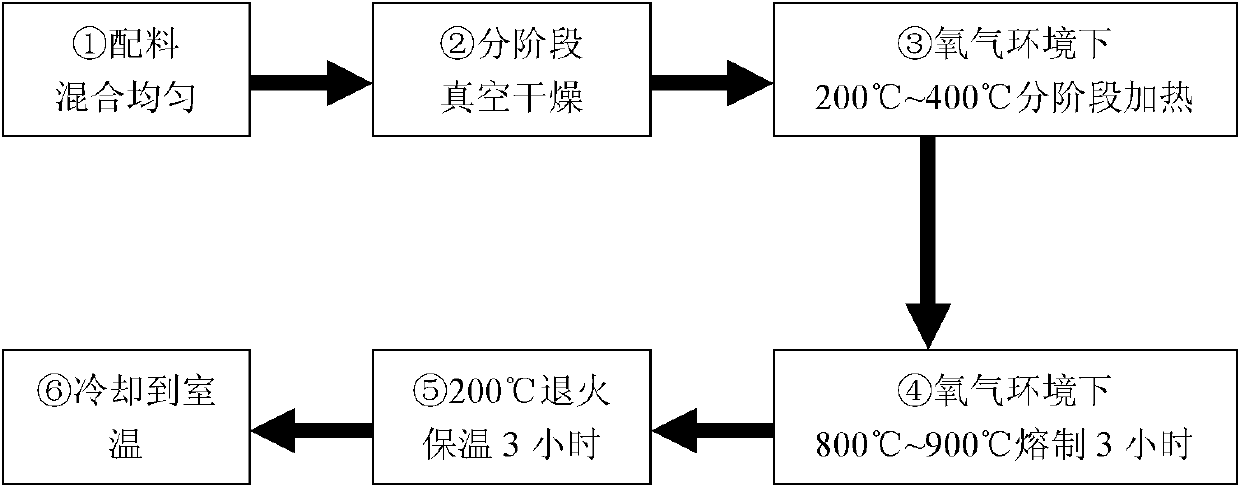

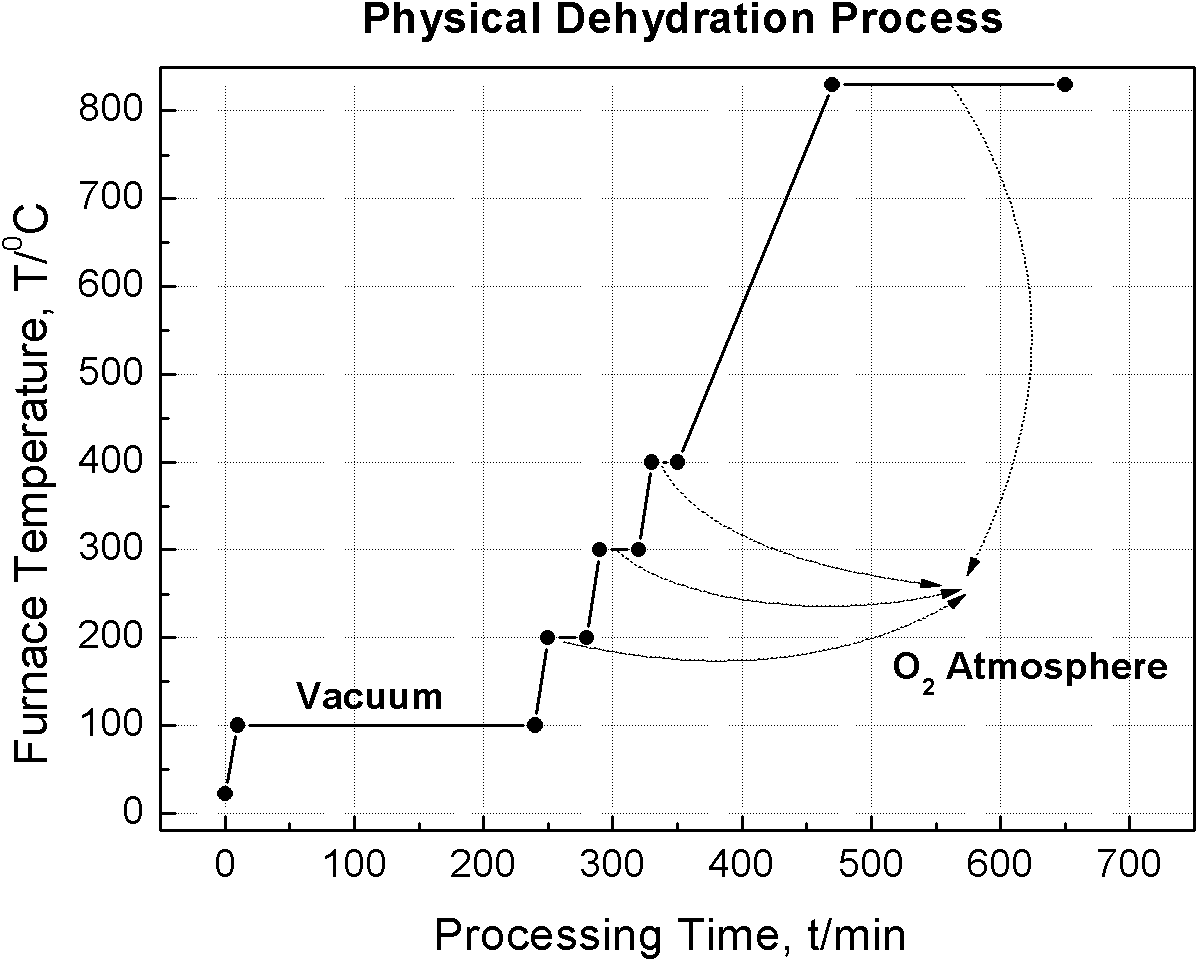

Method used

Image

Examples

Embodiment Construction

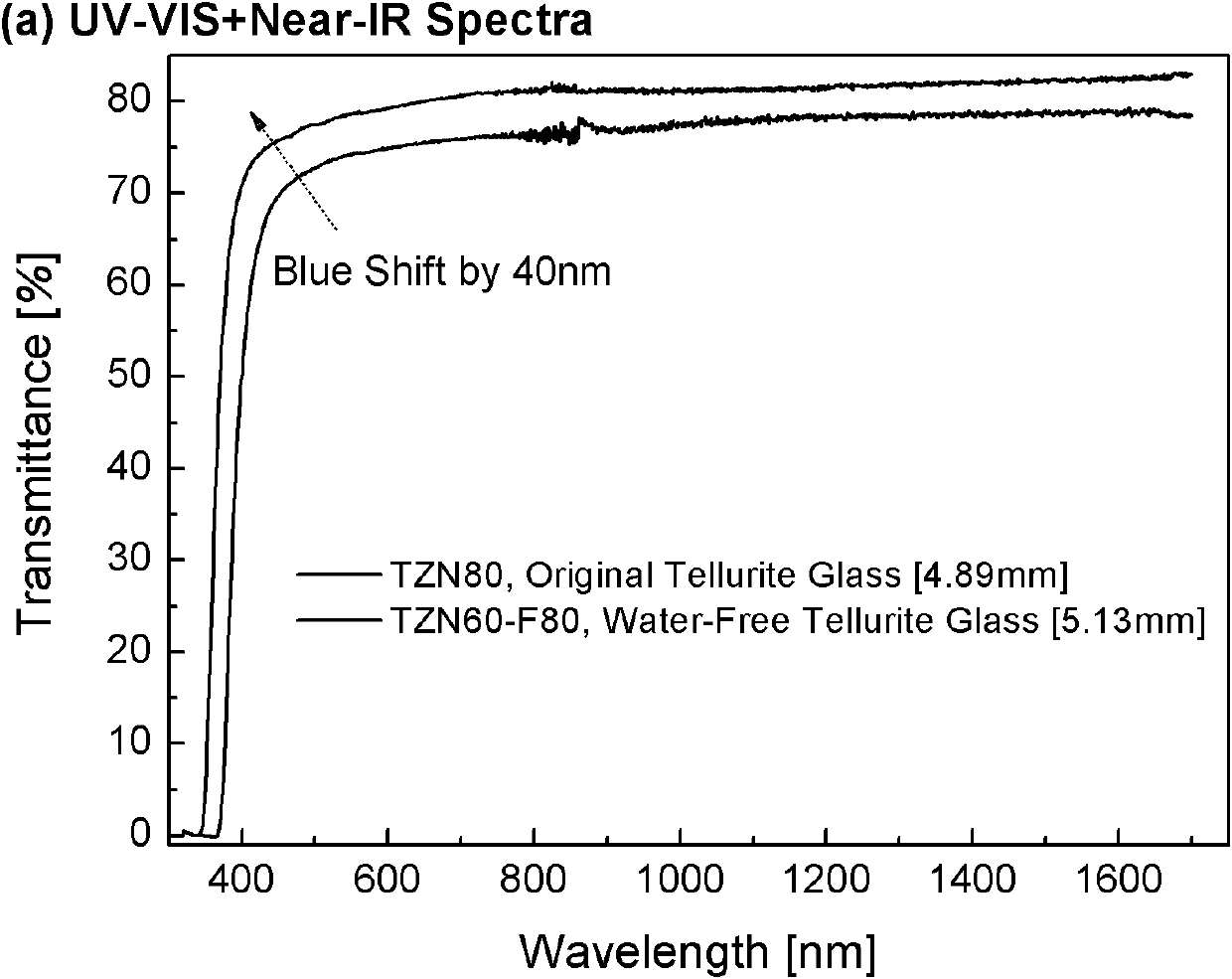

[0030] The invention provides a kind of mid-infrared anhydrous tellurate glass, the composition of the mid-infrared anhydrous tellurate glass includes: 55-80mol% TeO 2 And 15~45mol% ZnF 2 , in order to increase the mechanical strength of its material and increase its rare earth solubility to increase the practical application range, the composition of the mid-infrared anhydrous tellurate glass provided by the present invention also includes 5-20mol% of sodium ion compounds, such as Na 2 The unit of X is all possible, such as the commonly used Na 2 f 2 or Na 2 CO 3 .

[0031] Among the above components, the preferred components of the present invention include: 57-75mol% TeO 2 , 20~35mol% ZnF 2 And 5 ~ 15mol% of sodium ion compounds; more preferred components include: 60 ~ 70mol% of TeO 2 , 25~35mol% ZnF 2 And 5-10mol% sodium ion compound.

[0032] A sodium ion compound can be Na 2 f 2 or Na 2 CO 3 , or a mixture of the two; no matter which, as long as the compound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com