Perfusion type electronickelling and silicon carbide device for air cylinder

A nickel electroplating and perfusion technology, applied in electrolytic coatings, coatings, etc., can solve the problems of unstable distribution of silicon carbide particles, shortened service life of electroplating solution, increased waste water treatment costs, etc. Strong wear resistance and good cathodic polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments are only It is a part of embodiments of the present invention, but not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts shall fall within the protection scope of the present invention.

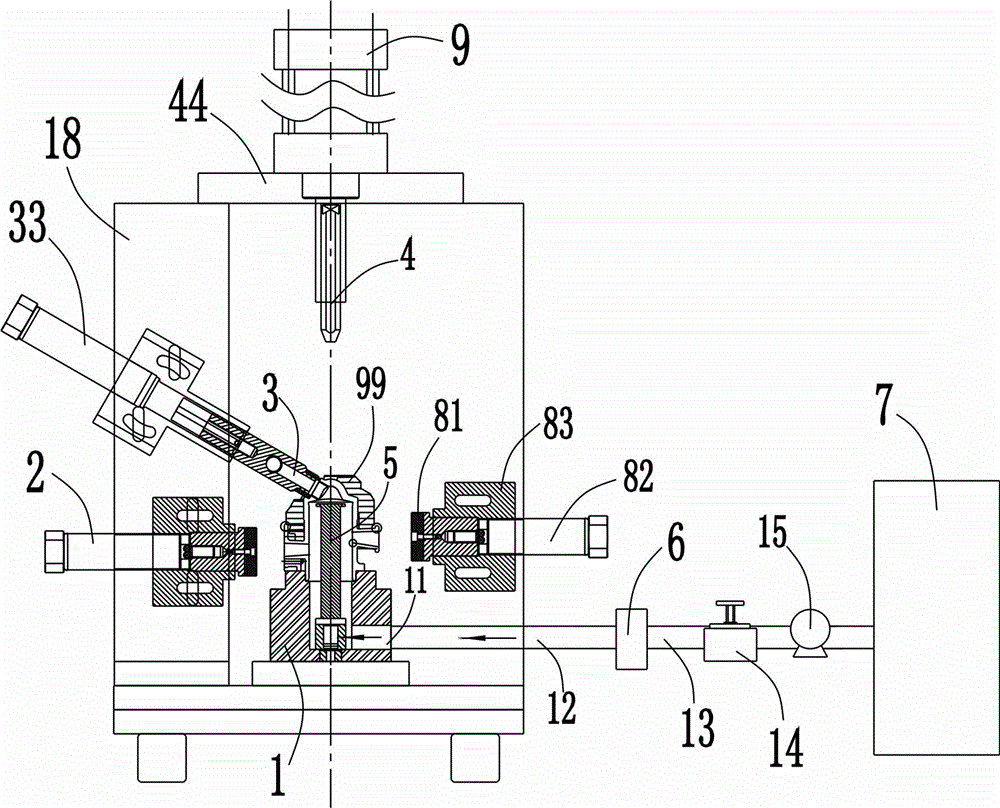

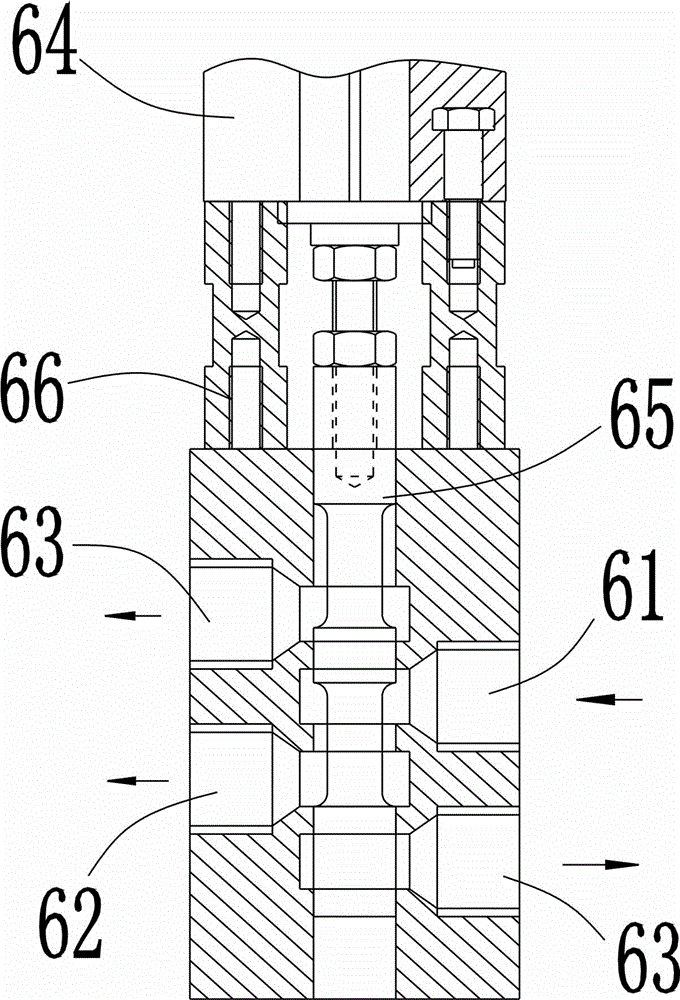

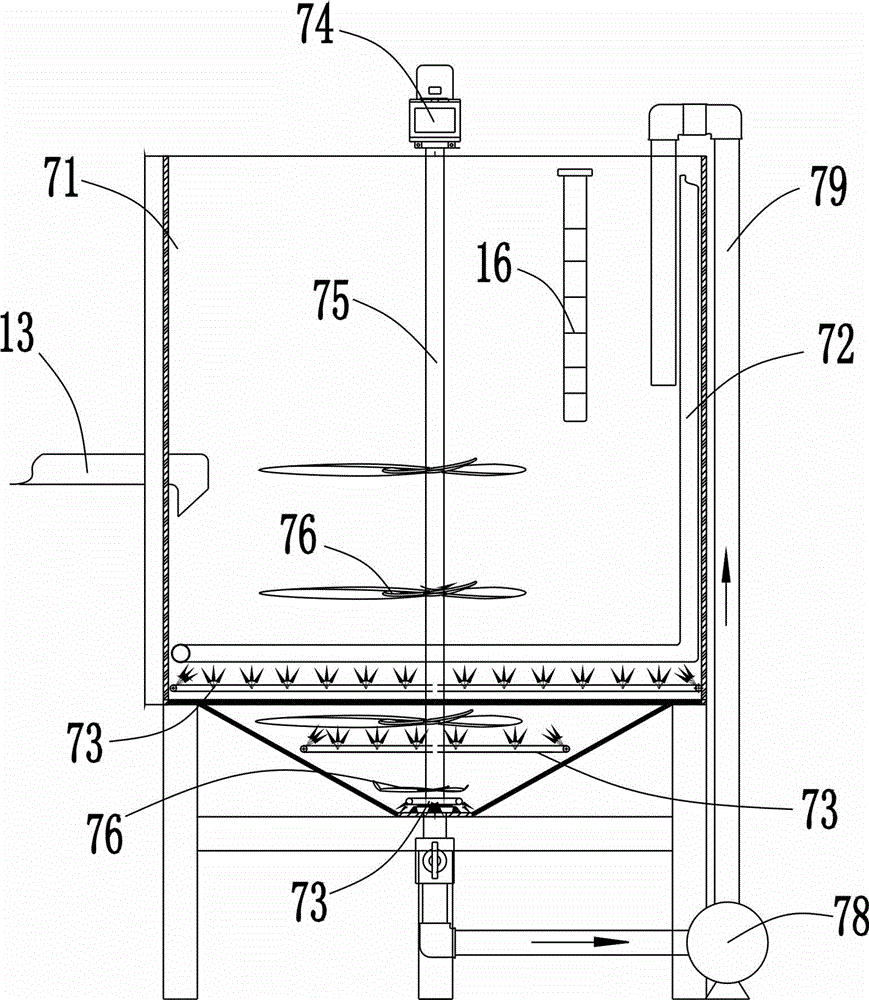

[0039] Such as Figure 1-3 As shown, a cylinder 045-0135 in practical application is used as the cylinder to be coated. A cylinder perfusion electroplating nickel and silicon carbide device, comprising a control device, a plating bath 7, a bracket 18 and an electroplating seat 1, a cathode conductive rod 4 and an anode conductive rod 5 arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com