Torsional vibration type hollow fiber membrane filtering device

A technology of torsional vibration and filtration device, applied in the field of water treatment, can solve the problems of concentration polarization, unfavorable filtration effect, membrane fouling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

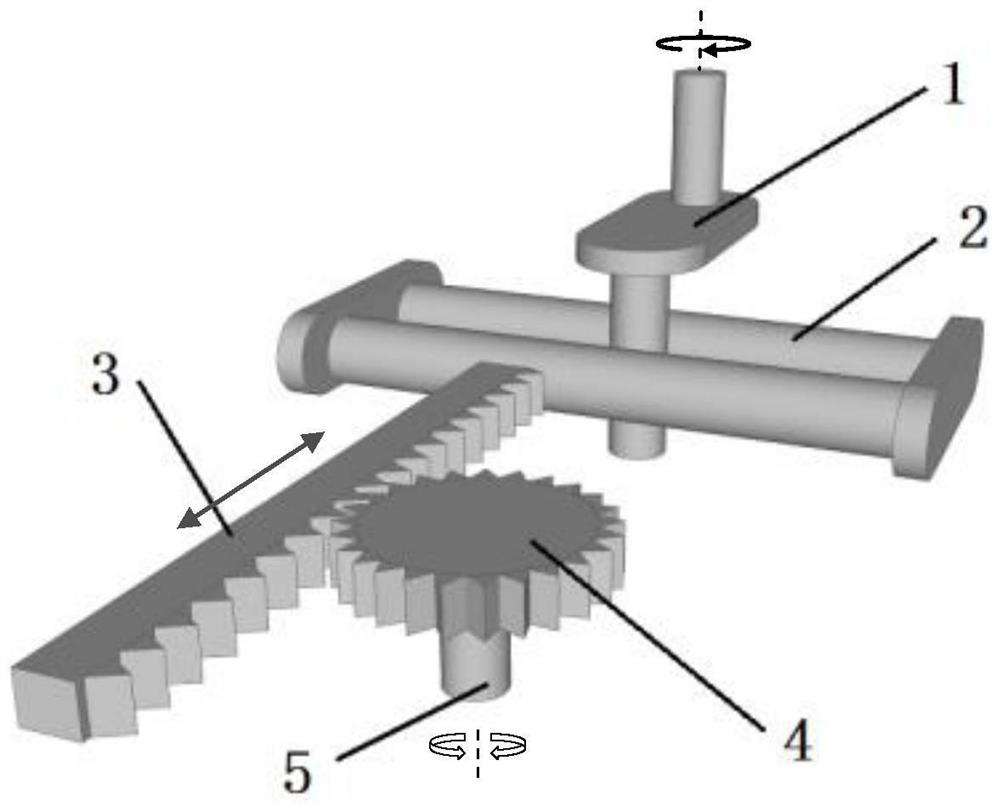

[0032] Such as figure 1 with figure 2 As shown, the torsional vibration type hollow fiber membrane filtration device provided by the present invention is made up of two main parts, is respectively common ultrafiltration system (comprising reactor, hollow fiber membrane module, pressure sensor, valve and suction pump) and twisting The vibration assembly, the torsional vibration assembly is a motion conversion structure, including: a rotating body 1, a rectangular frame 2, a rack 3 and a gear 4.

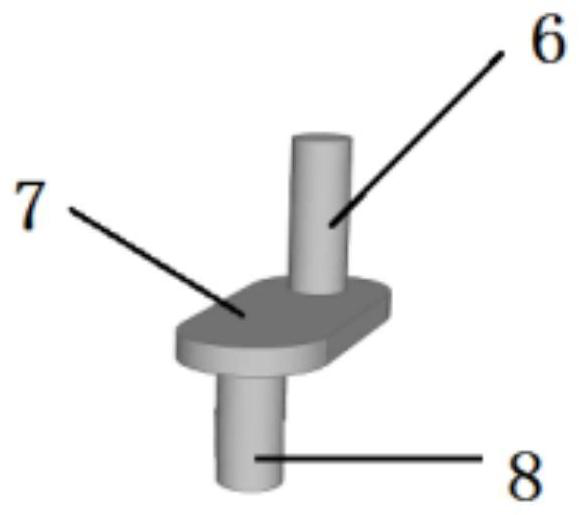

[0033] The rotating body 1 includes an upper connecting rod 6, a connecting piece 7 and a lower connecting rod 8, the upper connecting rod 6 and the lower connecting rod 8 are vertically installed on the two surfaces of the connecting piece 7 respectively, and the axis of the upper connecting rod 6 and the axes of the lower connecting rod 8 are parallel to each other and not collinear. Arranged in this way, when the upper connecting rod 6 of the motor drives the rotating body 1 rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com