A torsional vibration energy storage device

A technology of torsional vibration and energy, which is applied in the direction of vibration suppression adjustment, fluid using vibration, machine/engine, etc., can solve the problems that cannot be effectively used, and achieve the effect of compact structure, stable operation and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

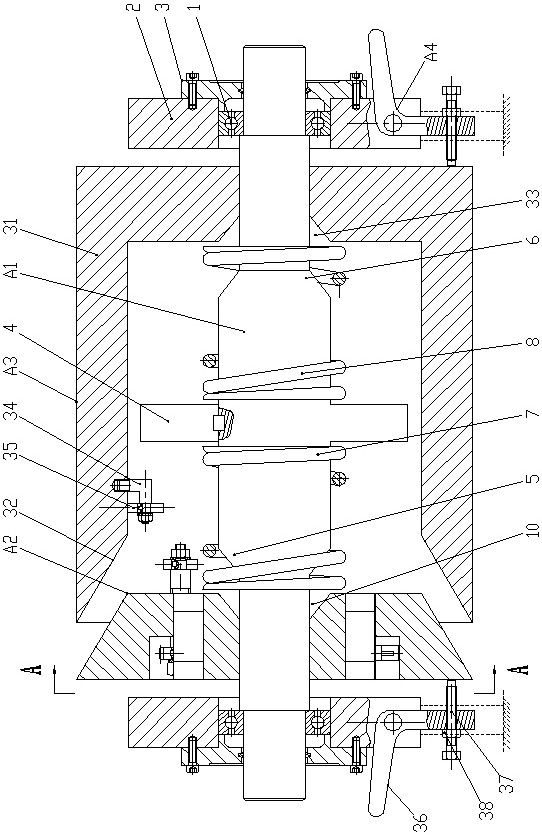

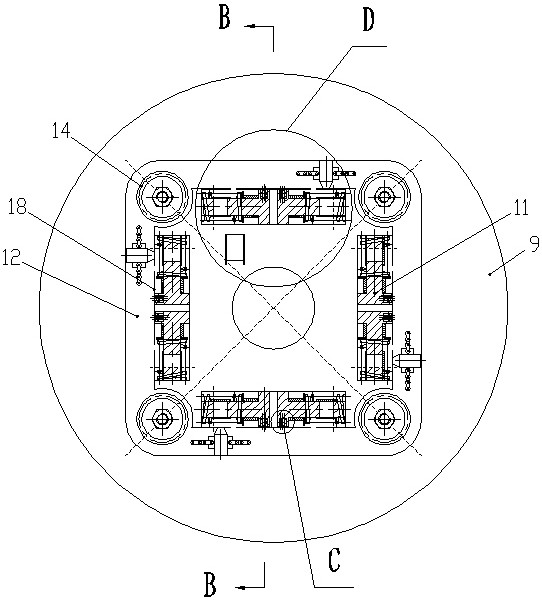

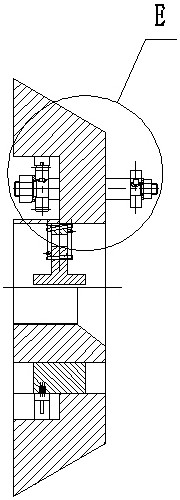

[0031] Such as Figure 1-6 As shown, a torsional vibration energy storage device of the present invention includes a transmission shaft A1, the left and right ends of the transmission shaft A1 are respectively connected to the bearing housing 2 through rolling bearings 1, wherein the bearing housing 2 is fixed with a rolling bearing 1 The bearing end cover 3 at the position; the bottom of each bearing seat 2 is provided with a set of pushing mechanism A4; the middle part of the transmission shaft A1 is fixed with a pressure plate 4;

[0032] There is a left conical transition structure 5 and a right conical transition structure 6 on the transmission shaft A1, and an energy collection system A2 is arranged between the left conical transition structure 5 and the bearing seat 2 on the left side of the transmission shaft A1, and the energy collection system A2 is connected to the right side of the transmission shaft A1. An energy release system A3 is provided between the bearing h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com