A turbulent flow electrolyzer and a turbulent flow electrolysis production system composed of turbulent flow electrolyzers

A production system and electrolysis system technology, which is applied in the electrolysis process, electrolysis components, photography process, etc., can solve the problems affecting electrolysis operations, different reaction conditions of electrolysis cells, deterioration of electrolysis cell conditions, etc., to improve electrolysis production efficiency, mechanical The operation method is feasible and the effect of reducing the power consumption of electrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

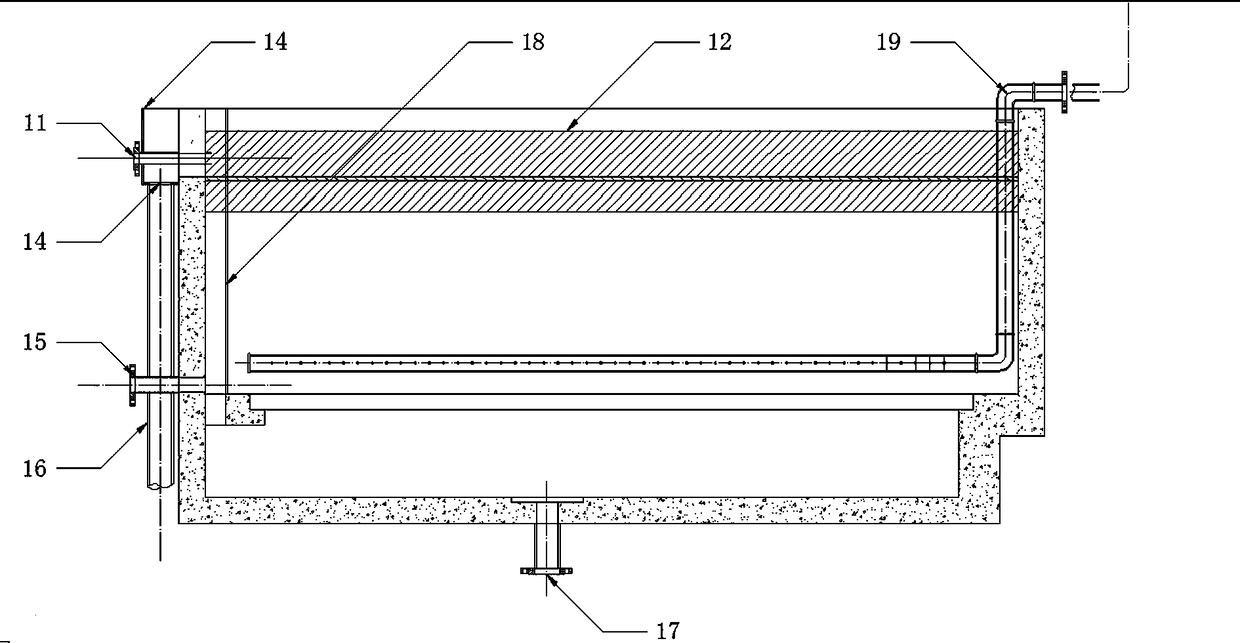

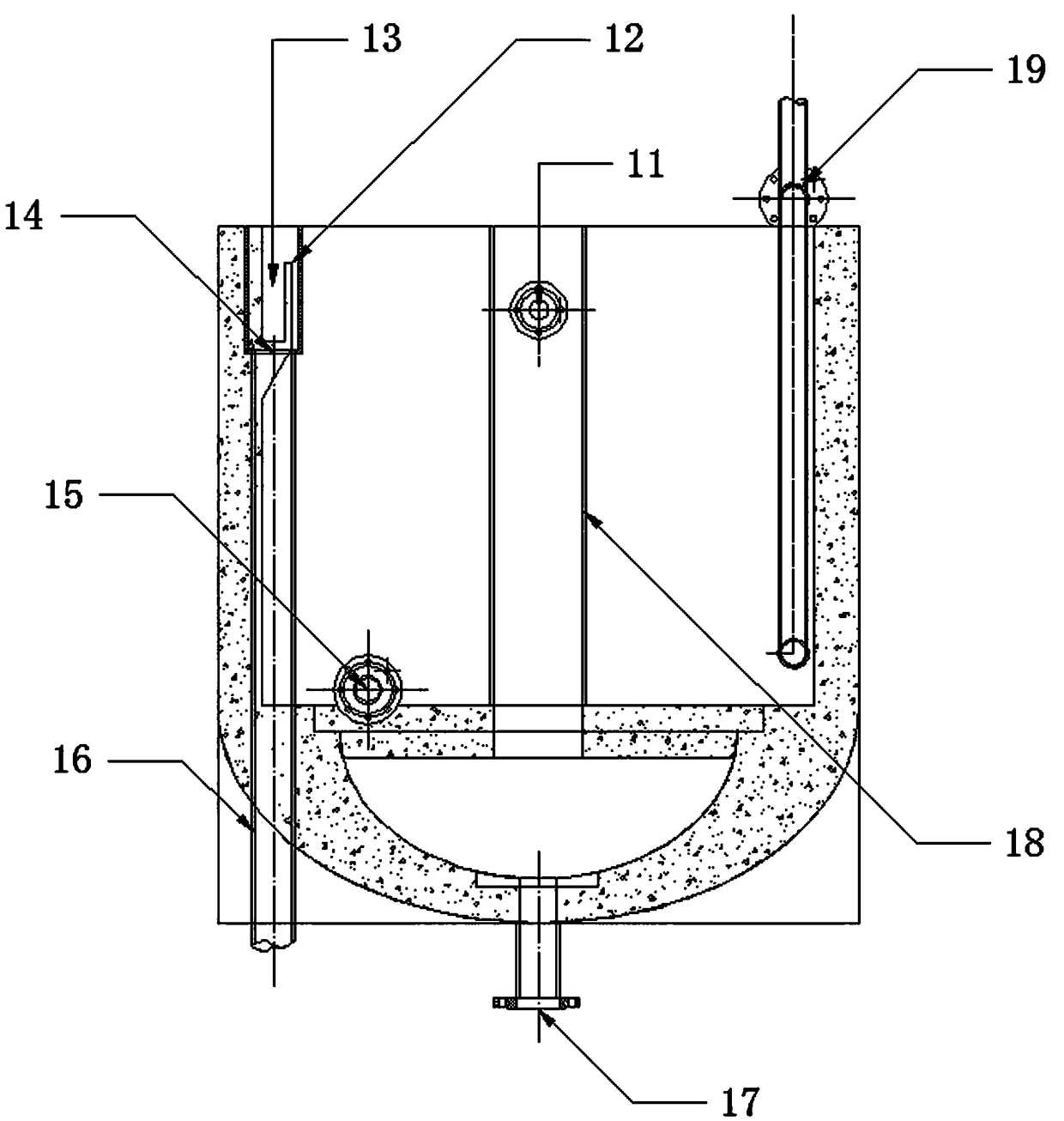

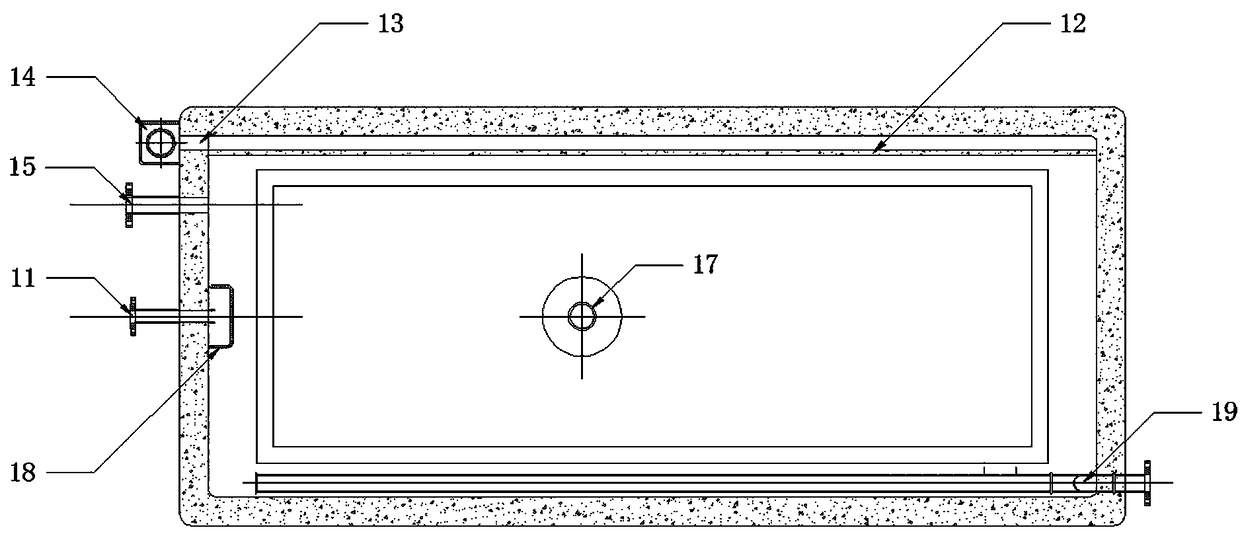

[0048] The electrolysis process of metal manganese of the present embodiment is mainly completed in the turbulent flow electrolyzer, and the structure of the turbulent flow electrolyzer is as figure 1 , figure 2 , image 3 As shown, it includes a tank body and a diaphragm frame that separates the inner space of the tank body into an anode chamber and a cathode chamber. A liquid inlet pipe 19 is also provided in the tank body. Wherein, the liquid outlet 11 is located 3 to 5 cm below the liquid surface of the electrolyte, and the liquid outlet 11 communicates with the anode chamber through the communication pipe 18 .

[0049] The bottom of the tank body is provided with a mud discharge port 17 communicating with the anode chamber, the side wall of the tank body is provided with a discharge port 15 located at the bottom of the cathode chamber, and liquid supply pipes corresponding to the position of the cathode plate are arranged on the liquid inlet pipe 19. hole.

[0050] A...

Embodiment 2

[0057] The production system of metal manganese in the present embodiment, as Figure 4 As shown, the production system of metal manganese composed of the above-mentioned turbulent-flow electrolyzers includes an electrolytic system 1, a circulation purification system 2, a cooling system 3, and a regulating system 4 connected in sequence. The electrolytic system 1 includes a plurality of turbulent-flow electrolyzers. The electrolytic cell group and the circulating liquid collection tank, the overflow port 14 and the discharge port 15 of each turbulent flow electrolytic cell are connected with the circulating liquid collection tank; the electrolysis system is connected with the circulation purification system through the circulating liquid collection tank, and the The liquid inlet pipe 19 is connected with the regulating system.

[0058] The specific process of using this production system to produce manganese metal is as follows:

[0059] 1. Driving for the first time:

[00...

Embodiment 3

[0080] In this embodiment, on the basis of the foregoing embodiments, a control system 5 is added for the production system of electrolytic manganese metal, such as Figure 4 As shown, the control system 5 is respectively connected with the electric control valve, temperature sensor, and pH value sensor in the electrolysis system 1 , the circulation purification system 2 , the cooling system 3 , and the adjustment system 4 . Thus, the production process parameter signals can be centrally fed back to the control system 5 through the temperature sensors and pH sensors of each system, and the control system controls various electric control valves to automatically adjust the electrolysis process parameters, which improves the efficiency of the manganese metal production process. Level of automation and mechanization. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com