Single ion polymer electrolyte, single ion polymer electrolyte composite film and preparation method thereof, and lithium ion battery

A polymer and single-ion technology, applied in the field of lithium-ion batteries, can solve problems such as low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

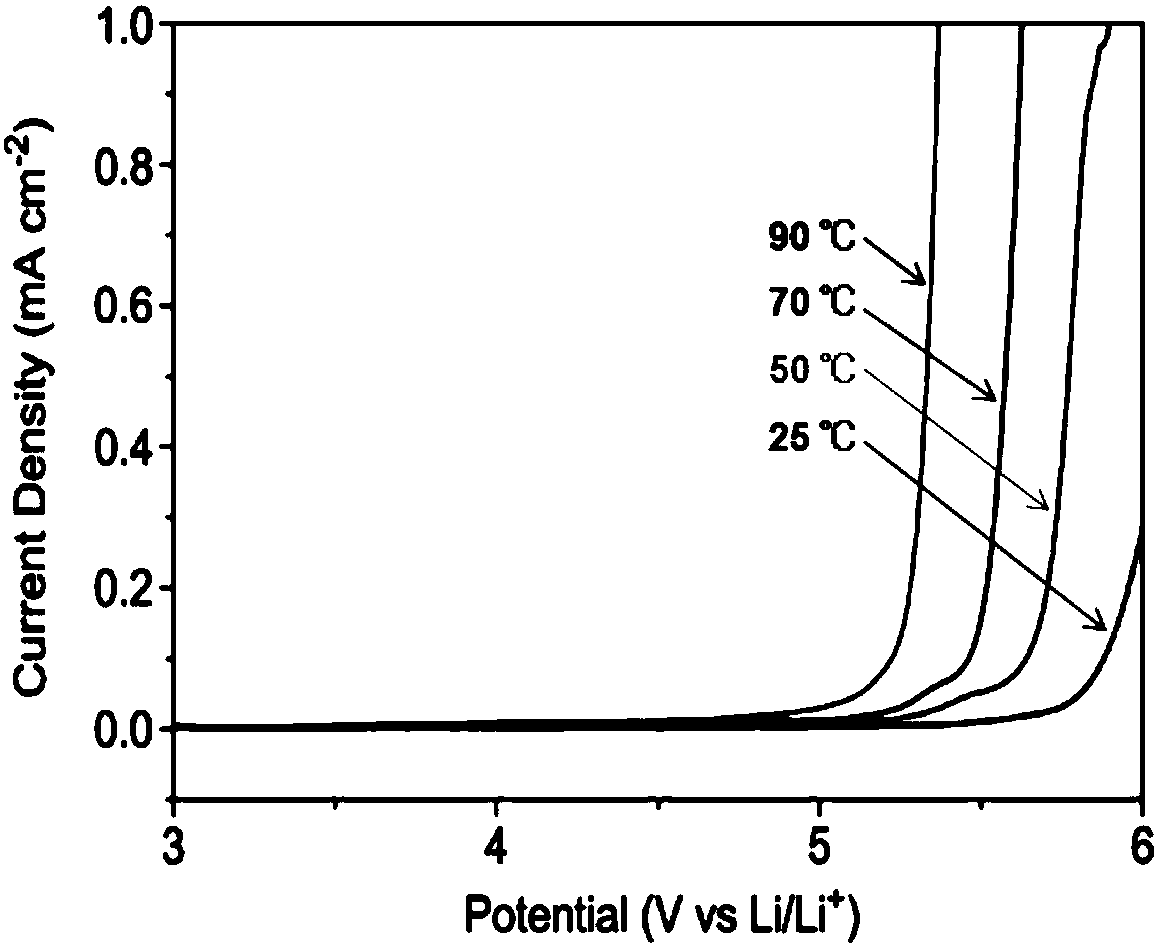

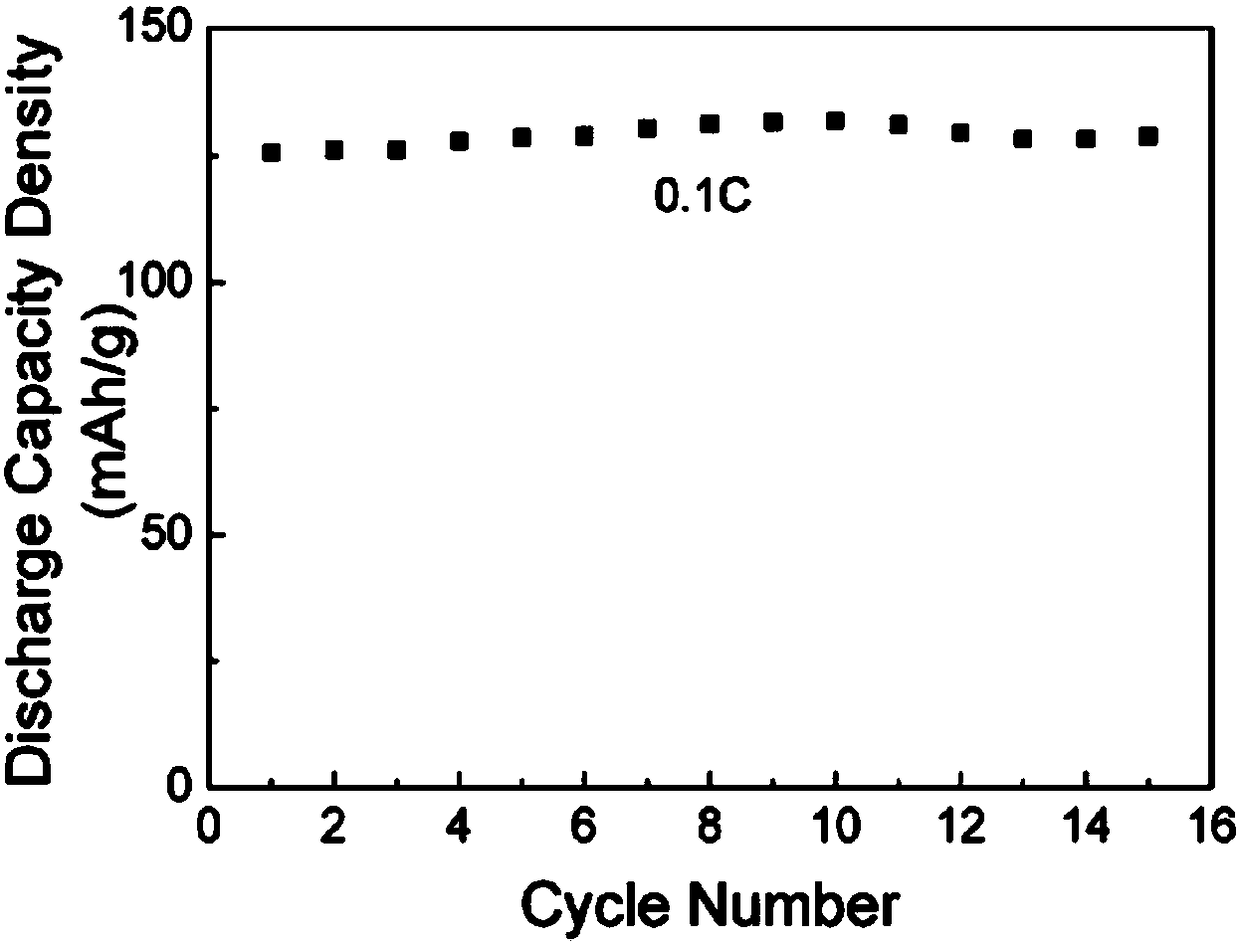

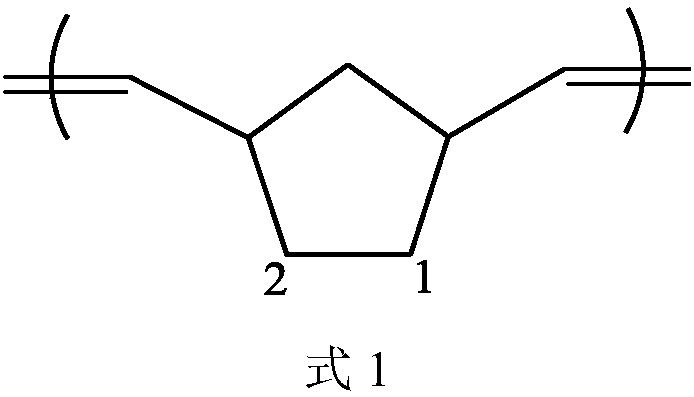

[0077] The single-ion polymer electrolyte in this embodiment includes a polymer chain composed of structural units shown in formula 1, a lithium ion-donating group is connected to the No. 1 position of a part of the structural units, and Lithium ion conducting group is connected to position 1, lithium ion donating group is connected to position 2 of some structural units, and lithium ion conducting group is connected to position 2 of another part of the structural unit . The molar ratio of lithium ion donating groups to lithium ion conducting groups is 1:2.

[0078] The lithium ion donating group has the structure shown in Formula 2. The lithium ion conducting group has the structure shown in formula 3, wherein m=10.

[0079] The single-ion polymer electrolyte membrane in this embodiment is composed of the following components: a single-ion polymer electrolyte and polyvinylidene fluoride-hexafluoropropylene, and the mass ratio of the single-ion polymer electrolyte to polyvin...

Embodiment 2

[0089] The single-ion polymer electrolyte in this embodiment includes a polymer chain composed of structural units shown in formula 1, a lithium ion-donating group is connected to the No. 1 position of a part of the structural units, and Lithium ion conducting group is connected to position 1, lithium ion donating group is connected to position 2 of some structural units, and lithium ion conducting group is connected to position 2 of another part of the structural unit . The molar ratio of lithium ion donating groups to lithium ion conducting groups is 1:1.

[0090] The lithium ion donating group has the structure shown in Formula 2. The lithium ion conducting group has the structure shown in formula 3, wherein m=14.

[0091] The single-ion polymer electrolyte membrane in this embodiment is composed of the following components: a single-ion polymer electrolyte and polyvinylidene fluoride-hexafluoropropylene, and the mass ratio of the single-ion polymer electrolyte to polyvin...

Embodiment 3

[0100] The single-ion polymer electrolyte in this embodiment includes a polymer chain composed of structural units shown in formula 1, a lithium ion-donating group is connected to the No. 1 position of a part of the structural units, and Lithium ion conducting group is connected to position 1, lithium ion donating group is connected to position 2 of some structural units, and lithium ion conducting group is connected to position 2 of another part of the structural unit . The molar ratio of lithium ion donating groups to lithium ion conducting groups is 2:1.

[0101] The lithium ion donating group has the structure shown in Formula 2. The lithium ion conducting group has the structure shown in formula 3, wherein m=16.

[0102] The single-ion polymer electrolyte membrane in this embodiment is composed of the following components: a single-ion polymer electrolyte and polyvinylidene fluoride-hexafluoropropylene, and the mass ratio of the single-ion polymer electrolyte to polyvin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com