A kind of single ion polymer electrolyte and preparation method thereof, single ion polymer electrolyte membrane, lithium ion battery

A technology of electrolyte membrane and polymer, which is applied in the field of lithium-ion batteries and can solve the problems of macroscopic phase separation of composite electrolytes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

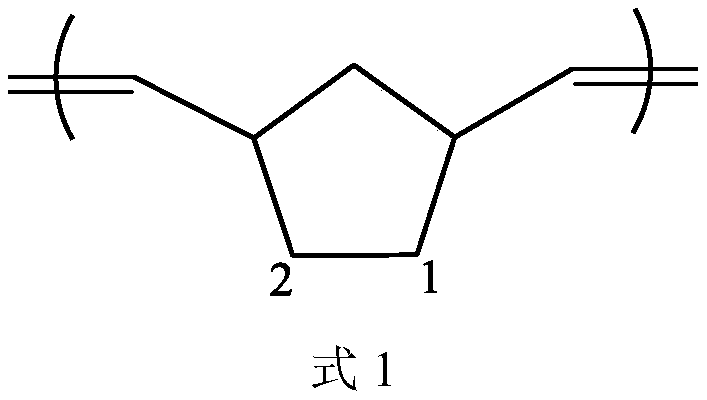

[0092] The single-ion polymer electrolyte in this embodiment is composed of many polymer chains, and the polymer chains are cross-linked to form a single-ion polymer electrolyte with a three-dimensional network cross-linking structure.

[0093] The single-ion polymer electrolyte in this embodiment includes a polymer chain composed of structural units shown in formula 1, and a membrane support group is connected between the two polymer chains. Specifically, one end of the membrane support group is connected to a The No. 1 or No. 2 position on a structural unit of the polymer chain, and the other end is connected to the No. 1 or No. 2 position on a structural unit of another polymer chain. Among the structural units that are not connected to the membrane support group on the polymer chain, a lithium ion-donating group is connected to the No. 1 position of the structural unit of a part of the polymer chain, and a lithium ion-providing group is connected to the No. 2 position of th...

Embodiment 2

[0110] The single-ion polymer electrolyte in this embodiment is composed of many polymer chains, and the polymer chains are cross-linked to form a single-ion polymer electrolyte with a three-dimensional network cross-linking structure.

[0111] The single-ion polymer electrolyte in this embodiment includes a polymer chain composed of structural units shown in formula 1, and a membrane support group is connected between the two polymer chains. Specifically, one end of the membrane support group is connected to a The No. 1 or No. 2 position on a structural unit of the polymer chain, and the other end is connected to the No. 1 or No. 2 position on a structural unit of another polymer chain. Among the structural units that are not connected to the membrane support group on the polymer chain, a lithium ion-donating group is connected to the No. 1 position of the structural unit of a part of the polymer chain, and a lithium ion-providing group is connected to the No. 2 position of th...

Embodiment 3

[0128] The single-ion polymer electrolyte in this embodiment is composed of many polymer chains, and the polymer chains are cross-linked to form a single-ion polymer electrolyte with a three-dimensional network cross-linking structure.

[0129] The single-ion polymer electrolyte in this embodiment includes a polymer chain composed of structural units shown in formula 1, and a membrane support group is connected between the two polymer chains. Specifically, one end of the membrane support group is connected to a The No. 1 or No. 2 position on a structural unit of the polymer chain, and the other end is connected to the No. 1 or No. 2 position on a structural unit of another polymer chain. Among the structural units that are not connected to the membrane support group on the polymer chain, a lithium ion-donating group is connected to the No. 1 position of the structural unit of a part of the polymer chain, and a lithium ion-providing group is connected to the No. 2 position of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com