Method for treatment of electroplating chromium-containing wastewater by periodic polarity reversal

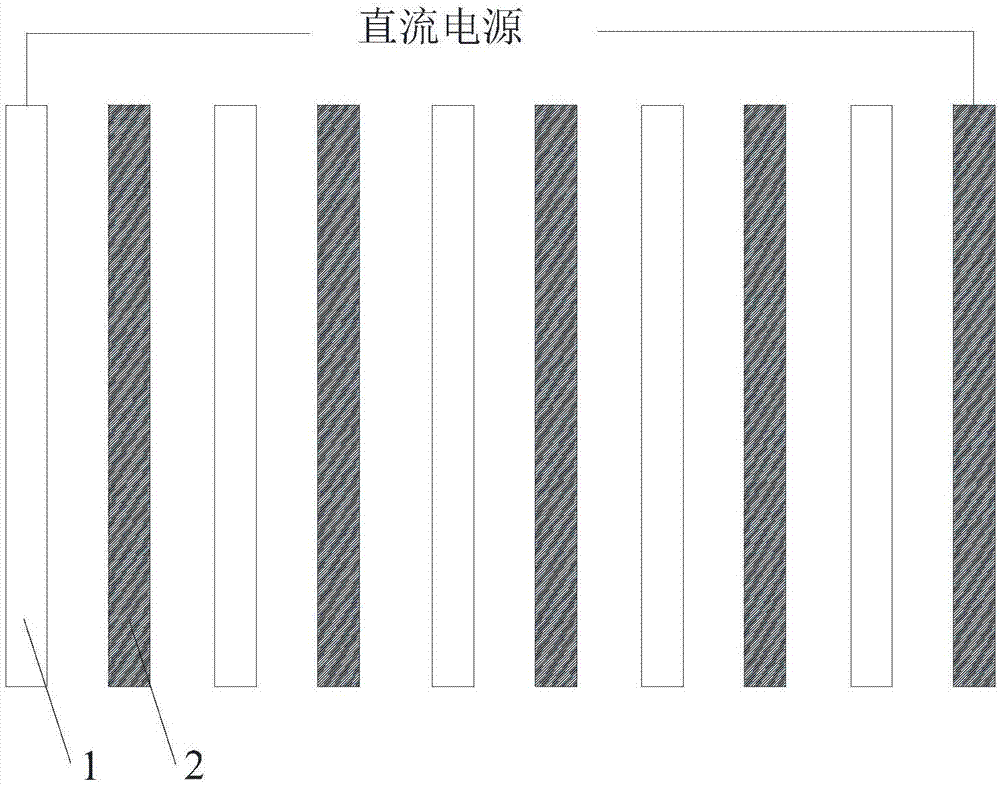

A chromium wastewater, periodic technology, applied in the direction of metallurgical wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of reduced current efficiency, poor precipitation effect, increased energy consumption, etc., achieve stable operation, prevent electrode Passivation, the effect of reducing construction cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

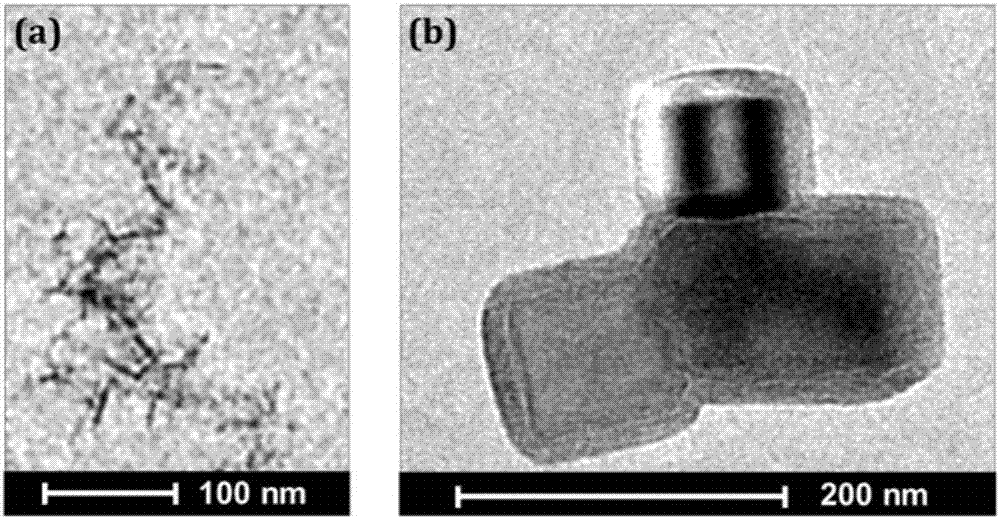

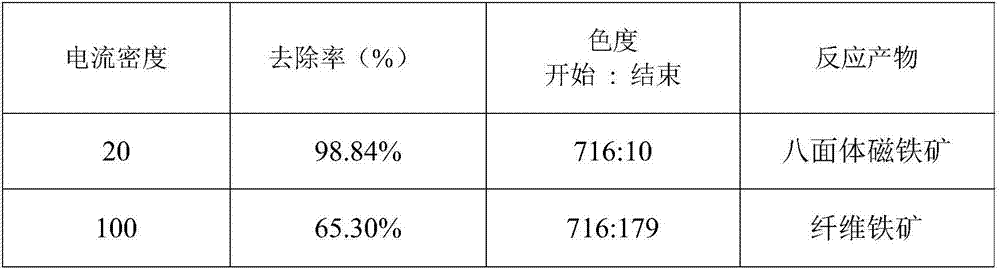

Method used

Image

Examples

Embodiment 1

[0046] The chromium content of electroplating wastewater is 100mg / L, the pH is adjusted to 5, the conductivity is 500μs / cm, the average electrolysis time is 20min, iron electrodes are used, the distance between the plates is 0.6cm, the average current density is 10μs / cm, and DC power is used. The pole inversion cycle is 5min / time, and samples are taken every 15min, and the absorbance is measured after 45min of precipitation. As the reaction progresses, Cr 6+ The removal rate gradually increased and stabilized after 30min, and a total of 180min was reacted. At this time, Cr 6+ The removal rate reaches 99.8%.

Embodiment 2

[0050] The chromium content of electroplating wastewater is 100mg / L, the pH is adjusted to 6, the conductivity is 700μs / cm, the average electrolysis time is 18min, and the arrangement of iron and aluminum plates is adopted. The distance between the plates is 1.0cm, the average current density is 20μs / cm, the DC power supply is used, the cycle of inversion is 5min / time, the samples are taken every 15min, and the absorbance is measured after 45min of precipitation. As the reaction progresses, Cr 6+ The removal rate gradually increased and stabilized after 30min, and a total of 180min was reacted. At this time, Cr 6+ The removal rate reaches 99.9%, and the chroma removal rate is 99.8%.

Embodiment 3

[0054] The chromium content of electroplating wastewater is 100mg / L, the pH is adjusted to 7, the conductivity is 1000μs / cm, the average electrolysis time is 15min, and the arrangement of iron and aluminum plates is adopted. The distance between the plates is 1.5cm, the average current density is 30μs / cm, the DC power supply is used, the cycle of inversion is 5min / time, the samples are taken every 15min, and the absorbance is measured after 45min of precipitation. As the reaction progresses, Cr 6+ The removal rate gradually increased and stabilized after 30min, and a total of 180min was reacted. At this time, Cr 6+ The removal rate reaches 99.9%, and the chroma removal rate is 99.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com