Cable semi-conductive shielding material and preparation method thereof

A shielding material and semi-conductive technology, applied in the direction of power cables with shielding/conducting layers, etc., can solve the problems of poor economy and difficult realization of cable manufacturing process, reduce the increase of electrical conductivity, reduce the amount of charge, and inhibit accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 50 grams of doped carbon black concentration is 30%wt low density polyethylene and 0.5 gram of antioxidant 1010 are put into Huck torque rheometer and mixed, and the mixing temperature is 378K, and the mixing time is 10 minutes, Then 1.15 g of dicumyl peroxide was put into a Haake torque rheometer and kneaded for 10 minutes, and the kneading temperature was kept at 378K. After post-crosslinking treatment, a semi-conductive shielding material that can be used for high-voltage DC plastic cables is obtained.

Embodiment 2

[0030] Put 35 grams of ethylene-vinyl acetate copolymers, 2 grams of antioxidant 1010, and 15 grams of conductive carbon black into the Hack Torque Rheometer for mixing. The mixing temperature is 378K, and the mixing time is 10 minutes. 1.15 g of dicumyl peroxide was put into a Haake torque rheometer and kneaded for 10 minutes, and the kneading temperature was kept at 378K. After post-crosslinking treatment, a semi-conductive shielding material that can be used for high-voltage DC plastic cables is obtained.

Embodiment 3

[0032] Put 35 grams of linear low-density polyethylene, 0.5 grams of antioxidant 1010, and 15 grams of superconducting carbon black into a Hack torque rheometer for mixing. The mixing temperature is 378K, and the mixing time is 15 minutes. 1.15 g of dicumyl peroxide was put into a Haake torque rheometer and kneaded for 15 minutes, and the kneading temperature was kept at 378K. After post-crosslinking treatment, a semi-conductive shielding material that can be used for high-voltage DC plastic cables is obtained.

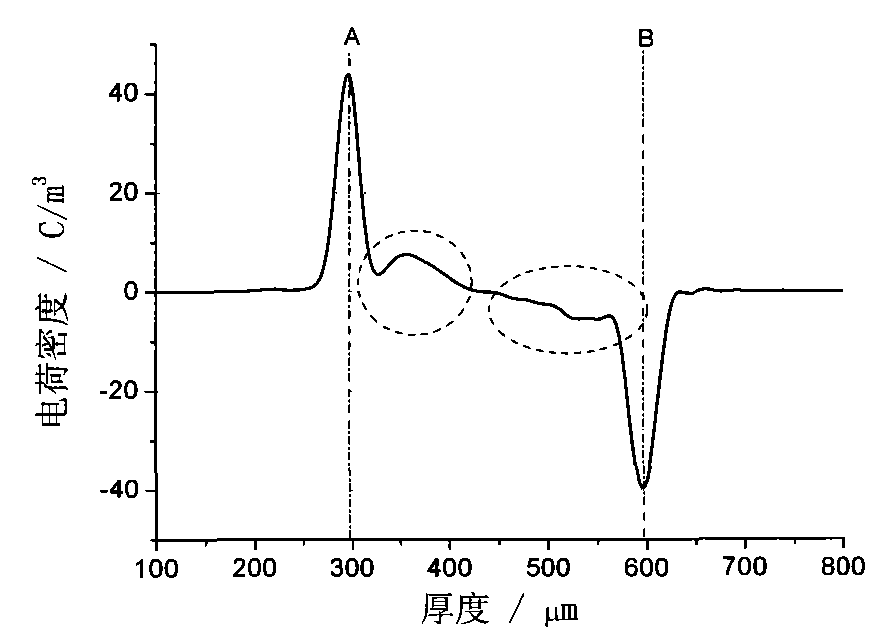

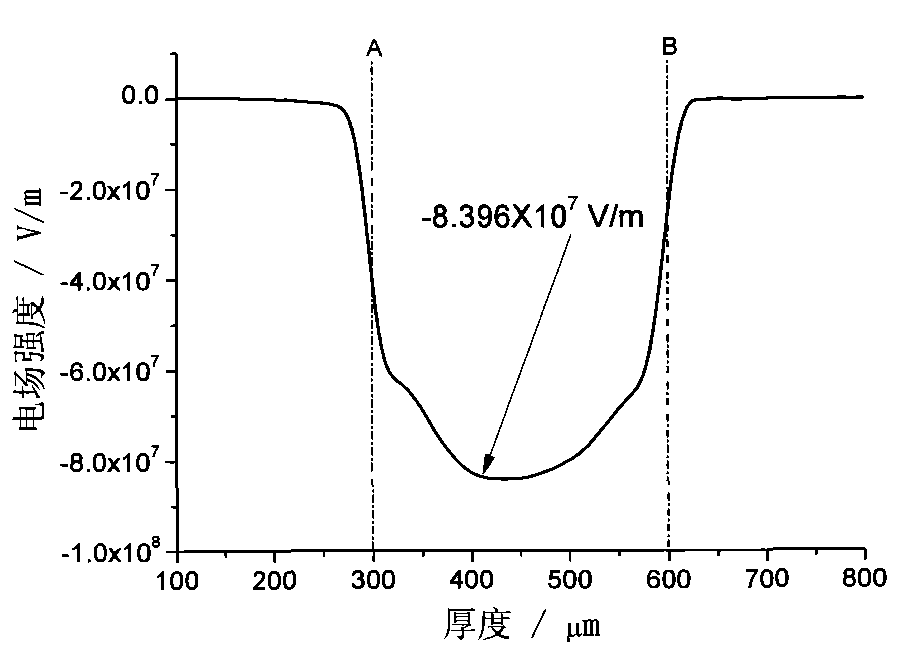

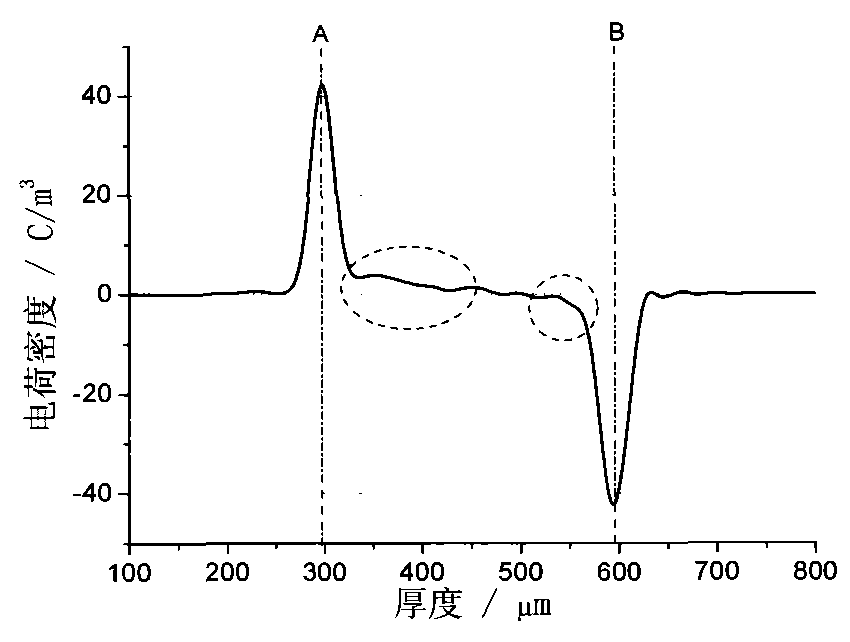

[0033] Using the materials prepared in the above Examples 1-3 as the semi-conductive shielding material, measure the space charge and electric field distribution of the insulating material XLPE when it is pressed for 60 minutes under an applied electric field of -60kV / mm, as shown in Fig. 1, Fig. 2 and Fig. 3 shows:

[0034]Under the external electric field of -60kV / mm, using the material prepared in Example 1, there is a large amount of injection of charges of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com