Three-layer composite wave-absorbing film and preparation method thereof

A layer composite and thin film technology, which is applied in the field of three-layer composite absorbing film and its preparation, can solve the problems of high cost, complex equipment, and difficult scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

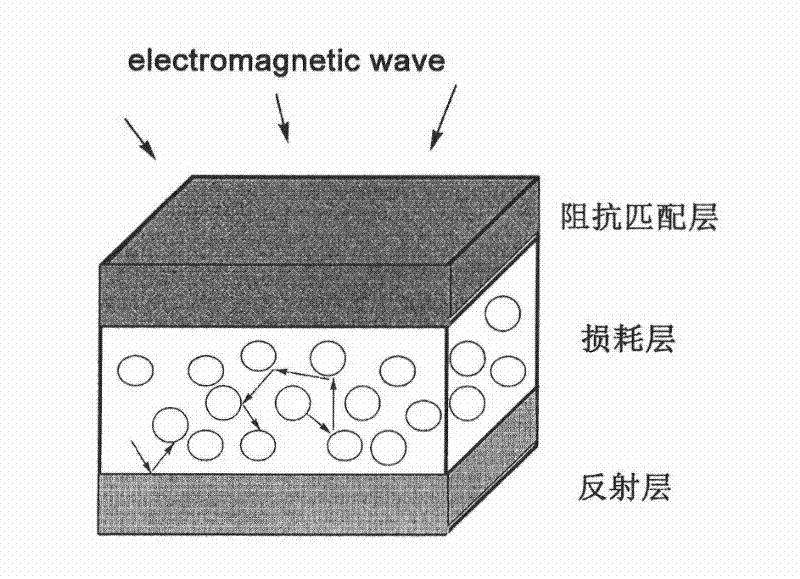

[0029] See attached figure 1 As shown, the three-layer composite absorbing film of the present invention is an impedance matching layer 1 composed of a dielectric material and an organic carrier, an absorbing layer 2 composed of magnetic particles and an organic carrier, and a carbon material with better conductivity and an organic carrier. The reflective layer 3 is composed of a carrier, the thickness of the impedance matching layer 1 is 0.1-0.3mm, the thickness of the absorbing layer 2 is 0.2-0.4mm, and the thickness of the reflective layer 3 is 0.1-0.3mm.

[0030] Table 1 is an embodiment of the material selection and thickness of the three-layer composite wave-absorbing film

[0031]

[0032]

[0033] Introduce the preparation method of three-layer composite wave-absorbing film of the present invention below with e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com