Preparation method of all-solid polymer electrolyte through in-situ ring opening polymerization of epoxy compound, and application of the all-solid polymer electrolyte in all-solid lithium battery

An all-solid-state polymer and epoxy-based compound technology, which is applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, electrolyte immobilization/gelation, etc., can solve the problems of high solid/solid interface impedance, poor rate and cycle performance And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

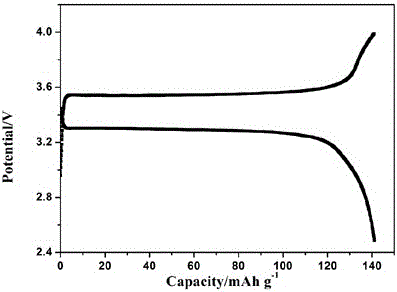

Embodiment 1

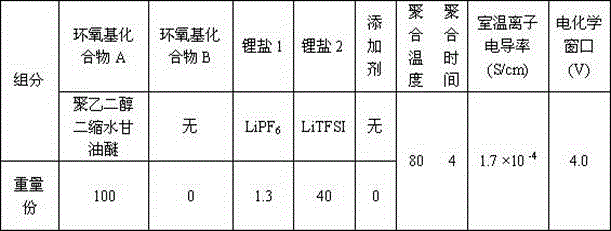

[0021] In a glove box filled with argon, LiTFSI, LiPF 6 Dissolve in polyethylene glycol diglycidyl ether monomer, and stir for 4 hours to mix evenly; inject the evenly mixed solution into Li / / SL (SL is a stainless steel pole piece), and place the SL / / SL battery at 80 o C for 4 hours, and then test the ionic conductivity and electrochemical stability window of the all-solid polymer electrolyte. Among them, polyethylene glycol diglycidyl ether and LiPF 6 , The mass ratio of LiTFSI is 100: 1.3: 40. The ratio of raw materials used to prepare solid polymer electrolytes is shown in the table, and the ion conductivity of the prepared polymer for lithium-ion batteries at room temperature is 1.7 × 10 -4 S / cm, the electrochemical window is 4.0V.

[0022] Table 1:

[0023]

Embodiment 2

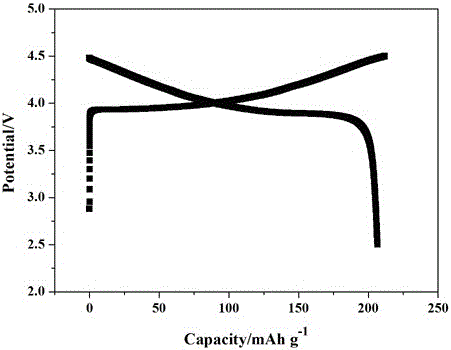

[0025] In a glove box filled with argon, LiTFSI, LiPF 6 Dissolve in polyethylene glycol diglycidyl ether monomer, add lithium lanthanum zirconium oxide nanoparticles, and then magnetically stir for 4 hours to mix evenly; inject the evenly mixed solution into Li / / SL (SL is a stainless steel pole piece), SL / / SL 30 in the battery o C for 4 hours, and then test the ionic conductivity and electrochemical stability window of the all-solid polymer electrolyte. Among them, polyethylene glycol diglycidyl ether and LiPF 6 The mass ratio of LiTFSI to lithium lanthanum zirconium oxide is 100:6:35:7. The ratio of raw materials used to prepare solid polymer electrolytes is shown in the table, and the ion conductivity of the prepared polymer for lithium-ion batteries at room temperature is 2.0 × 10 -4 S / cm, the electrochemical window is 4.8V.

[0026] Table 2:

[0027]

Embodiment 3

[0029] In a glove box filled with argon, LiTFSI, LiPF 6 Dissolve epoxy monomethoxypolyethylene glycol ether in polyethylene glycol diglycidyl ether monomer, add Al2O3 nanoparticles and then magnetically stir for 4 hours to mix evenly; inject the evenly mixed solution into Li / / SL (SL is a stainless steel pole piece), put 80 in SL / / SL battery o C for 4 hours, and then test the ionic conductivity and electrochemical stability window of the all-solid polymer electrolyte. Among them, polyethylene glycol diglycidyl ether and epoxy monomethoxypolyethylene glycol ether, LiPF 6 The mass ratio of , LiTFSI and aluminum oxide is 80 : 20 : 6 : 35 : 7. The ratio of raw materials used to prepare solid polymer electrolytes is shown in the table, and the ion conductivity of the prepared polymer for lithium-ion batteries at room temperature is 1.4 × 10 -4 S / cm, the electrochemical window is 4.8V.

[0030] table 3:

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com