Carbon nanotube/polylactic acid conductive composite material and preparation method

A technology of conductive composite materials and carbon nanotubes, which is applied in the field of polymer materials, can solve problems such as complex processing conditions and unsatisfactory material conductivity, and achieve the effects of easy operation and control, reduced addition amount, and simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

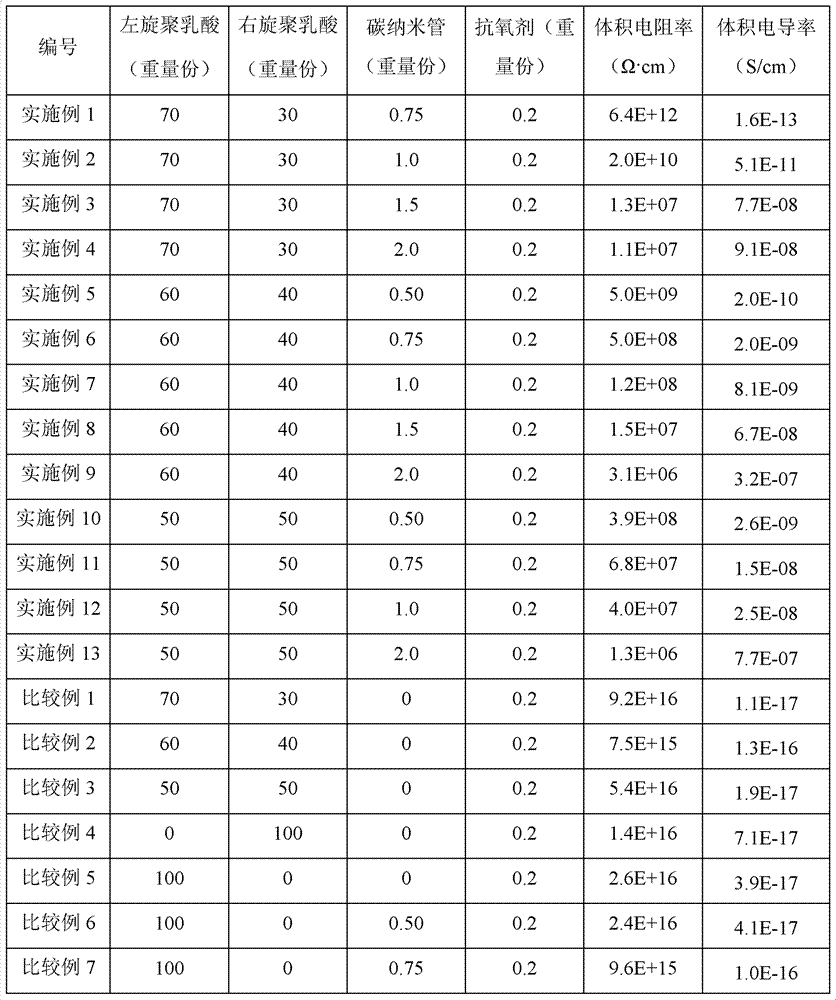

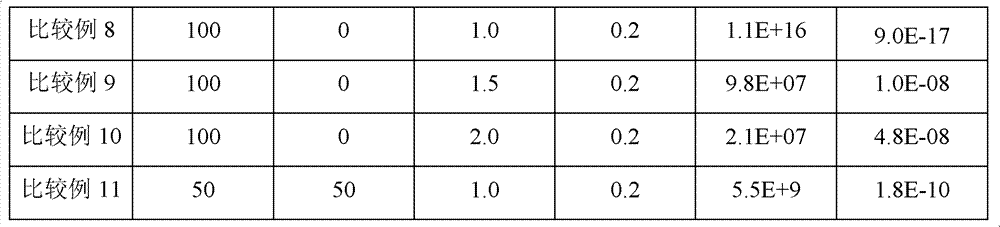

Embodiment 1~13

[0027] (1) PLLA (provided by Natureworks, brand 3051D) and PDLA (provided by Purac) were vacuum-dried at 80°C for 5 h, and then PLLA and CNTs (MWNTs, provided by Cheaptubes, diameter 20-30 nm, length 20-30 μm) and anti- The weight of oxygen agent (tetra[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and tri(2,4-di-tert-butyl) phenyl phosphite ratio of 1:1) in a Haake torque rheometer at 190°C and 60rpm for 10 minutes to obtain a CNTs / PLLA masterbatch, and then melt blended the masterbatch and PDLA at 220°C and 60rpm for 10 minutes to obtain CNTs / PLLA / PDLA composites. The material ratio of each embodiment is shown in Table 1.

[0028](2) The CNTs / PLLA / PDLA composite material after melt blending is molded into a circular sample with a diameter of 10cm and a thickness of 1.5mm for electrical performance testing. The test instrument is a PC68 megger, and the test standard is GB T 1410- In 2006, the measured volume resistivity and electrical conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com