Method for preparing hard polyurethane foam plastics with soybean oil

A technology of rigid polyurethane and foamed plastics, applied in the field of preparing rigid polyurethane foamed plastics from soybean oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

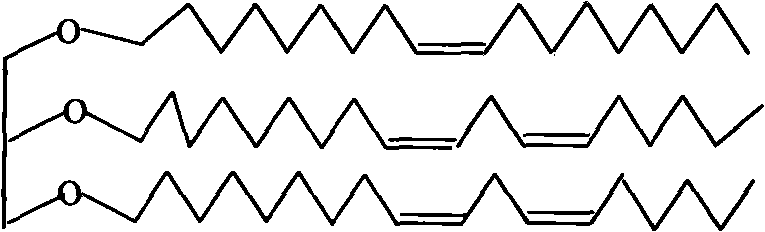

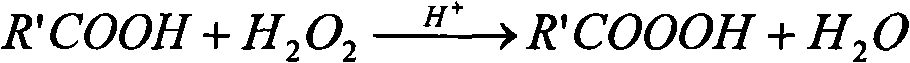

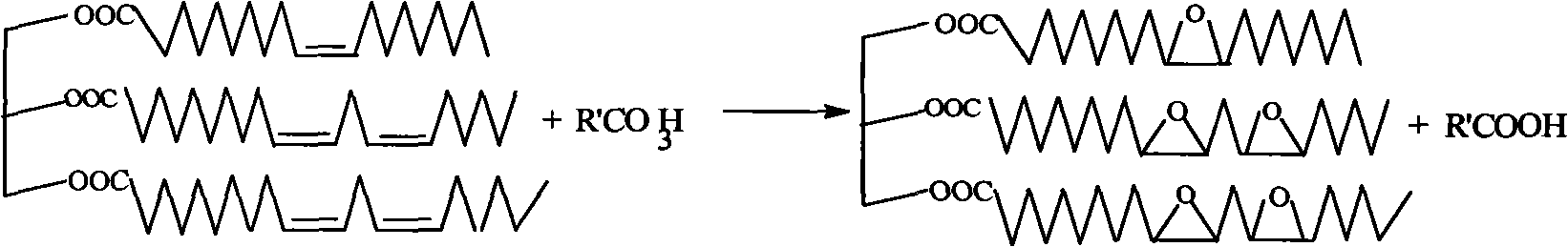

[0060] 1. Preparation of Epoxidized Soybean Oil

[0061] Add 125 grams of soybean oil, 30 grams of acetic acid (99%), and 2.5 grams of sulfuric acid (98%) in a 500ml four-necked round-bottom flask with an electric stirring device, a measuring thermometer, a dropping funnel, and a spherical condenser, and stir slowly Slowly heat up to 40°C, slowly add 60 grams of hydrogen peroxide (50%) into the dropping funnel, keep the reaction temperature at 50-70°C, and keep stirring for 3.5 hours after the dropwise addition. Stand to cool and stratify, separate the lower layer of acid water, add 50-60°C 5% NaOH solution to the oil layer to neutralize to about PH6-7, then wash 2-3 times with 50-60°C saturated NaCl solution and 60ml pure water, reduce Press and vacuum 130KPa to remove residual moisture (heating temperature 83° C.), filter to obtain 135 grams of product epoxy soybean oil. Detection of epoxy value: 6.35%, iodine value: 2.5gI 2 / 100g

[0062] 2. Preparation of soybean oil-ba...

Embodiment 2

[0074] 1. Preparation of Epoxidized Soybean Oil

[0075] Add 125 grams of soybean oil, 25 grams of formic acid (99%), and 2.0 grams of sulfuric acid (98%) in a 500ml four-necked round bottom flask with electric stirring, measuring thermometer, dropping funnel, and spherical condenser, and slowly Heat up to 40°C, slowly add 60 grams of hydrogen peroxide (50%) into the dropping funnel, keep the reaction temperature at 50-70°C, keep stirring for 3.0 hours after the dropwise addition. Stand to cool and separate the layers, separate the acid water in the lower layer, add 5% NaOH solution at 50-60°C to neutralize the oil layer to about pH 6-7, then wash with 50-60°C saturated NaCl solution and 60ml pure water for 2-3 times, reduce Press and vacuum 110KPa to remove residual moisture (heating is controlled at 81° C.), and filter to obtain 137 grams of product epoxy soybean oil. Detection of epoxy value: 6.43%, iodine value: 1.5gI 2 / 100g

[0076] 2. Preparation of Mixed Hydroxy Fat...

Embodiment 3

[0090] 1. Preparation of Epoxidized Soybean Oil

[0091] Add 100 grams of soybean oil, 15 grams of formic acid (99%), and 2.5 grams of phosphoric acid (85%) in a 500ml four-necked round-bottomed flask with electric stirring, measuring thermometer, dropping funnel, and spherical condenser, and stir slowly Heat up to 40°C, slowly add 55 grams of hydrogen peroxide (50%) into the dropping funnel, keep the reaction temperature at 50-70°C, keep stirring for 3.5 hours after the dropwise addition. Stand to cool and stratify, separate the lower layer of acid water, add 50-60°C 5% Na2CO3 solution to the oil layer to neutralize to about pH6-7, then wash with 50-60°C saturated NaCl solution and 40ml pure water for 2-3 times, reduce Press and evacuate at 115KPa to remove residual moisture (heating temperature is controlled at 82° C.), filter to obtain 108.5 grams of product epoxy soybean oil. Detection of epoxy value: 6.33%, iodine value: 3gI 2 / 100g

[0092] 2. Mixed hydroxy fatty acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com