Hydrothermal synthesis method of molybdenum disulfide nano flowers

A molybdenum disulfide, hydrothermal synthesis technology, applied in the direction of molybdenum sulfide, nanotechnology, etc., can solve the problem of low purity of molybdenum disulfide nanoflowers, and achieve the effect of improving the purity and ensuring the purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A hydrothermal synthesis method of molybdenum disulfide nanoflowers, comprising the following steps:

[0029] (1) Prepare 0.72g of sodium molybdate and 1g of thioacetamide, where thioacetamide is used both as a sulfur source and as a reducing agent;

[0030] (2) Mix all the above-mentioned prepared materials into 30mL deionized water, and stir to make it evenly mixed;

[0031] (3) Put the mixed liquid obtained in step (2) into the reaction autoclave for heating, so that the substances in the mixed liquid can react. During the reaction, the temperature is 180°C, and the heating time is 28h;

[0032] (4) Wait for the solution obtained in step (3) to cool down naturally, then carry out cyclic washing and centrifugation on the solution, and after 3 cycles, dry the obtained precipitate under vacuum at 65°C to obtain disulfide Molybdenum nanoflowers.

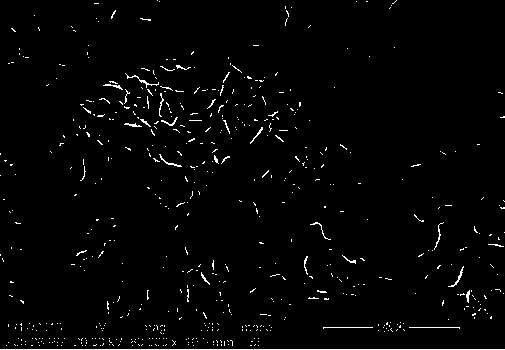

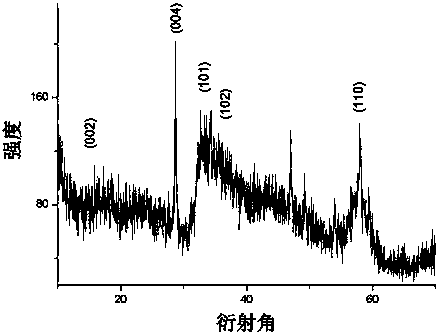

[0033] Such as figure 1 It is the scanning electron microscope image of the hydrothermally synthesized molybdenum disulfid...

Embodiment 2

[0035] A hydrothermal synthesis method of molybdenum disulfide nanoflowers, comprising the following steps:

[0036] (1) Prepare 0.72g of sodium molybdate and 1.14g of thiourea, wherein thiourea is used as both a sulfur source and a reducing agent;

[0037] (2) Mix all the above-mentioned prepared materials into deionized water, and stir to mix evenly;

[0038] (3) Put the mixed liquid obtained in step (2) into a polytetrafluoroethylene-lined container, and then put the container into a reaction autoclave for heating, so that the substances in the mixed liquid can react. During the reaction, the temperature is 240 ℃, heating time is 20h;

[0039] (4) Wait for the solution obtained in step (3) to cool down naturally, then carry out cyclic washing and centrifugation on the solution, and after 5 cycles, dry the obtained precipitate under vacuum at 55°C to obtain disulfide Molybdenum nanoflowers.

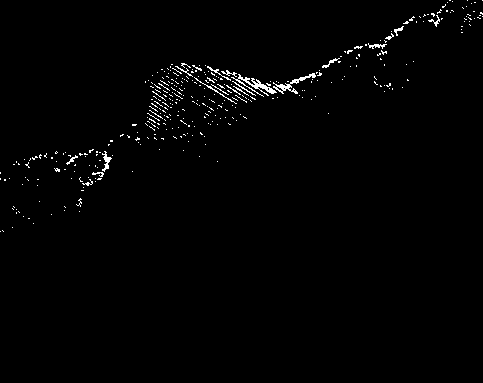

[0040] Such as image 3 It is an ultra-high resolution transmission electron mi...

Embodiment 3

[0042] A hydrothermal synthesis method of molybdenum disulfide nanoflowers, comprising the following steps:

[0043] (1) Prepare 0.84g of sodium molybdate and 1.20g of thiourea, wherein thiourea is used as both a sulfur source and a reducing agent;

[0044] (2) Mix all the above-mentioned prepared materials into deionized water, and stir to mix evenly;

[0045] (3) Put the mixed liquid obtained in step (2) into a polytetrafluoroethylene-lined container, and then put the container into a reaction autoclave for heating, so that the substances in the mixed liquid can react. During the reaction, the temperature is 200 ℃, heating time is 24h;

[0046] (4) Wait for the solution obtained in step (3) to cool down naturally, then carry out cyclic washing and centrifugation on the solution, and after 4 cycles, dry the obtained precipitate under vacuum at 60°C to obtain disulfide Molybdenum nanoflowers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com