Preparation method of one-step hydrothermal synthesis of carbon/molybdenum disulfide composite microsphere

A technology of molybdenum disulfide and composite microspheres, applied in the directions of molybdenum sulfide, vanadium oxide, etc., can solve problems such as no public reports, and achieve the effects of high yield, wide application prospect and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

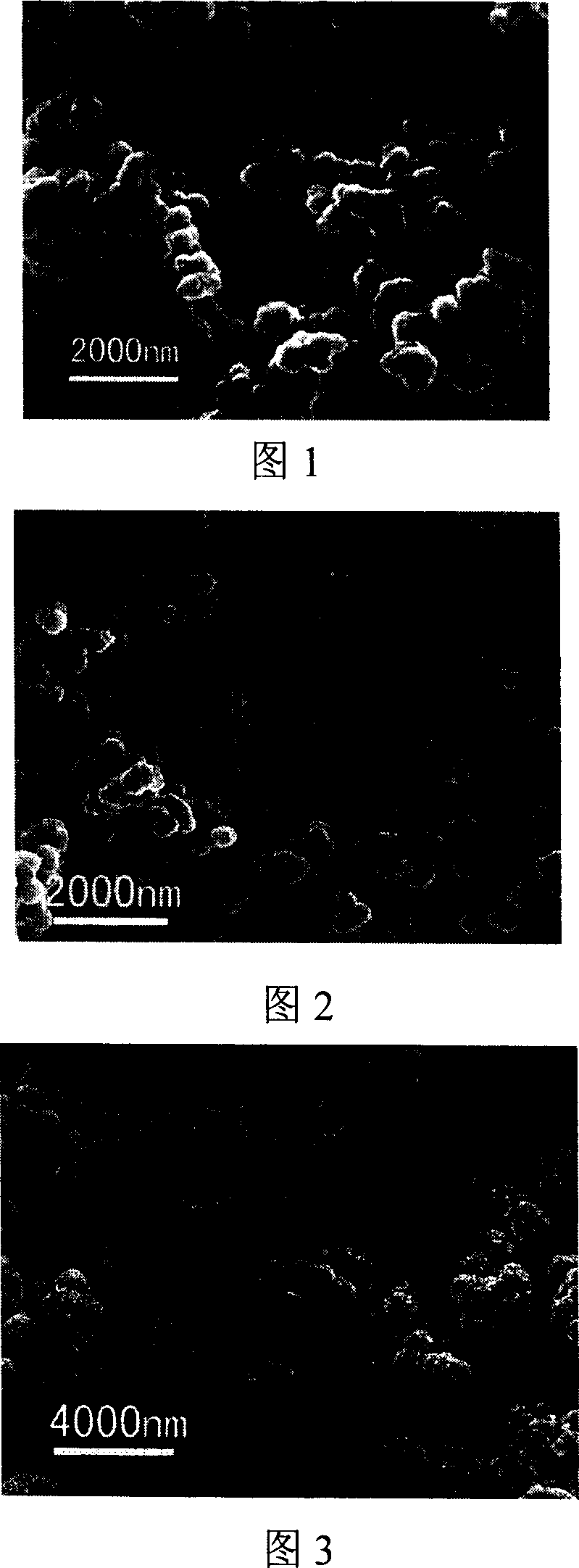

[0021] Dissolve 1.2mmol sodium molybdate in 60ml deionized water to form a 0.02M solution, add 5.3mmol of thiourea and stir evenly, then add 15mmol of glucose, wherein the molar ratio of thiourea to sodium molybdate is 4.4:1, glucose and The molar ratio of sodium molybdate was 12.5:1. After fully stirring, the solution was transferred to a hydrothermal reaction kettle, and hydrothermally reacted at 240°C for 24 hours, then cooled naturally, collected and collected after being fully washed with centrifugal separation and deionized water The carbon / molybdenum disulfide composite microspheres can be obtained after drying, and the microspheres have a uniform particle size as observed by SEM, and the average particle size is 0.40 microns (see Figure 1).

Embodiment 2

[0023] Dissolve 1.2mmol sodium molybdate in 60ml deionized water to form a 0.02M solution, add 5.4mmol of thioacetamide and stir evenly, then add 17mmol of glucose, wherein the molar ratio of thioacetamide to sodium molybdate is 4.5: 1. The molar ratio of glucose to sodium molybdate is 14.2:1. After fully stirring, transfer the solution to a hydrothermal reaction kettle, conduct a hydrothermal reaction at 230°C for 23 hours, then cool naturally, wash thoroughly with centrifuge and deionized water, collect and dry to obtain carbon / molybdenum disulfide composite microparticles. Balls with an average particle size of 0.44 microns (see Figure 2).

Embodiment 3

[0025] Dissolve 3.0mmol sodium molybdate in 60ml deionized water to form a 0.05M solution, add 15mmol of thiourea and stir evenly, then add 45mmol of glucose, wherein the molar ratio of thiourea to sodium molybdate is 5:1, glucose and molybdenum The molar ratio of sodium bicarbonate is 15:1. After fully stirring, the solution is transferred to a hydrothermal reaction kettle, hydrothermally reacted at 220°C for 21 hours, then cooled naturally, and then collected and dried with centrifugation and deionized water. The carbon / molybdenum disulfide composite microspheres can be obtained, and the average particle size is 1.3 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com