Anode material zirconium and phosphor adulterated lithium cobaltate of lithium ion secondary battery and its making method

A secondary battery and positive electrode material technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as increased internal resistance of batteries, poor cycle performance, and surface structure damage, and achieve improved cycle performance and safety performance , Improve structural stability and ensure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

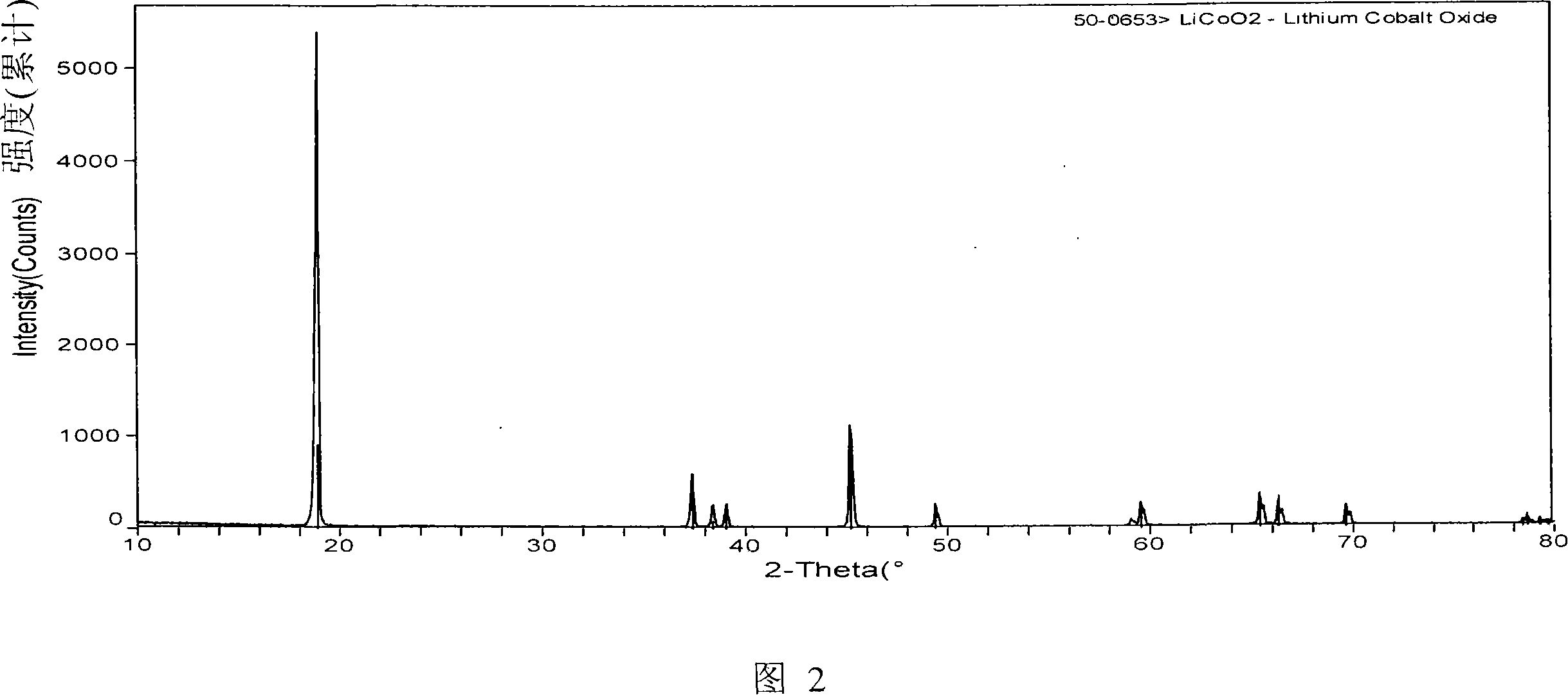

[0020] A lithium ion secondary battery cathode material zirconium, phosphorus doped lithium cobalt oxide, its chemical formula is:

[0021] LiZr x co (1-x-y) P y o 2 , where x=0.02, y=0.04, has a layered structure.

[0022] The preparation method of the above-mentioned lithium ion secondary battery cathode material zirconium, phosphorus doped lithium cobalt oxide comprises the following steps:

[0023] 1). According to the atomic ratio of lithium and cobalt of 1.03:1.00, 2000.0 grams of cobalt carbonate and 687.6 grams of lithium hydroxide were mixed uniformly;

[0024] 2). Put the mixed raw materials into a roasting furnace, and roast them in an air atmosphere. The roasting temperature is 900°C, and the roasting time is 12 hours;

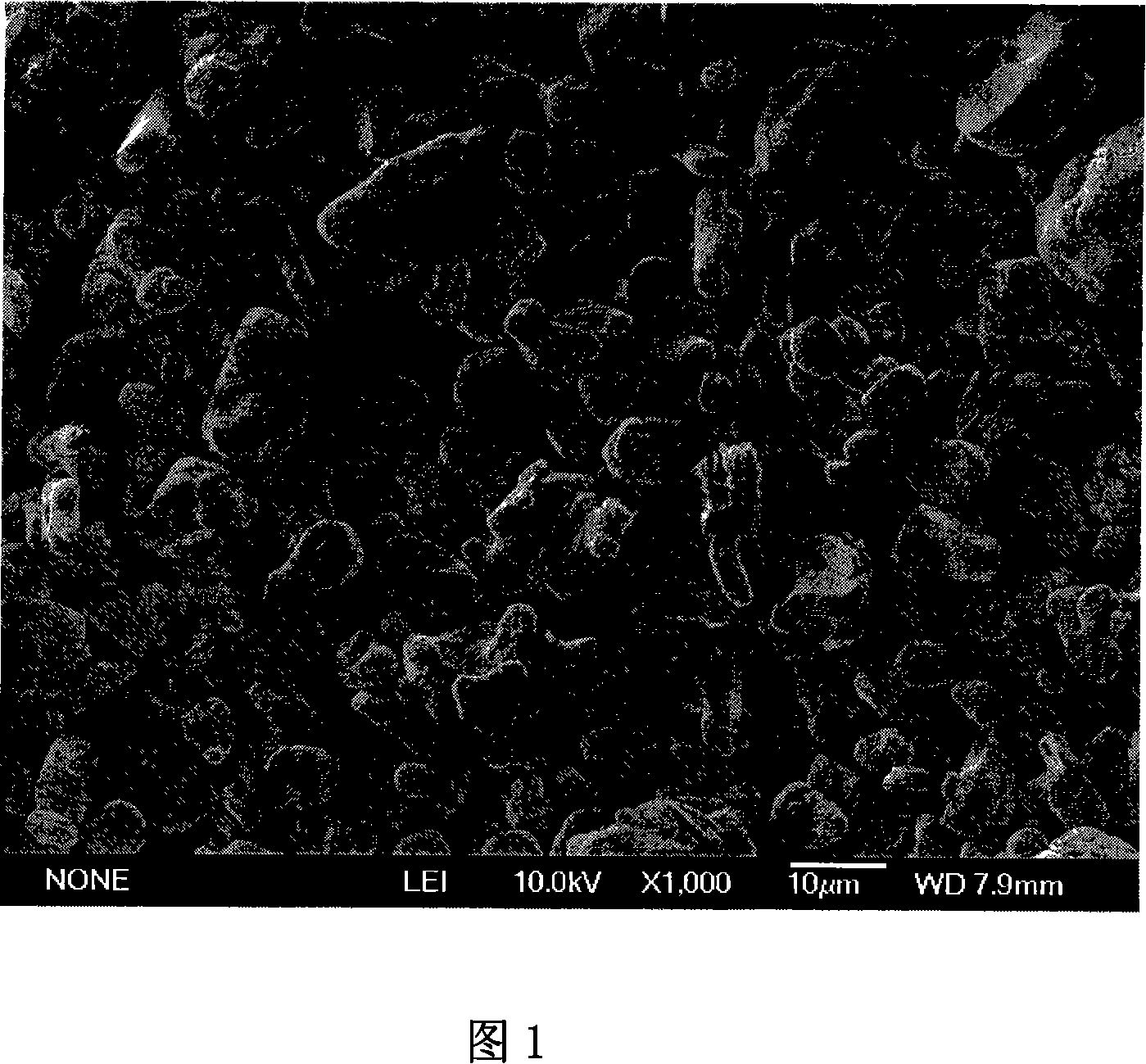

[0025] 3). Grinding the calcined lithium cobalt oxide, the average particle size of the powder is D 50 10 ~ 12um;

[0026] 4). Put 1000.0 grams of lithium cobaltate powder into the reaction kettle, add 2000.0 grams of water and stir to form ...

Embodiment 2

[0031] A lithium ion secondary battery cathode material zirconium, phosphorus doped lithium cobalt oxide, its chemical formula is:

[0032] LiZr x co (1-x-y) P y o 2 Where x=0.01, y=0.02, it has a layered structure.

[0033] The preparation method of the above-mentioned lithium ion secondary battery cathode material zirconium, phosphorus doped lithium cobalt oxide comprises the following steps:

[0034] 1). According to the atomic ratio of lithium and cobalt of 1.02:1.00, 1000.0 grams of tricobalt tetroxide and 470.1 grams of lithium carbonate are uniformly mixed;

[0035] 2). Put the mixed raw materials into a roasting furnace and roast in an air atmosphere at a roasting temperature of 800°C and a roasting time of 24 hours;

[0036] 3). Grinding the calcined lithium cobalt oxide, the average particle size of the powder is D 50 6 ~ 8um;

[0037] 4). Put 1,000.0 grams of lithium cobaltate powder into the reaction kettle, add 1,000.0 grams of water and stir to form a slur...

Embodiment 3

[0042] A lithium ion secondary battery cathode material zirconium, phosphorus doped lithium cobalt oxide, its chemical formula is:

[0043] LiZrx co (1-x-y) P y o 2 , where x=0.03, y=0.06, has a layered structure.

[0044] The preparation method of the above-mentioned lithium ion secondary battery cathode material zirconium, phosphorus doped lithium cobalt oxide comprises the following steps:

[0045] 1). According to the atomic ratio of lithium and cobalt of 0.98:1.00, 1000.0 grams of cobalt tetroxide and 451.6 grams of lithium carbonate were mixed uniformly;

[0046] 2). Put the mixed raw materials into a roasting furnace, and roast in an air atmosphere, the roasting temperature is 1000°C, and the roasting time is 6 hours;

[0047] 3). Grinding the calcined lithium cobalt oxide, the average particle size of the powder is D 50 13 ~ 15um;

[0048] 4). Put 1,000.0 grams of lithium cobaltate powder into the reaction kettle, add 3,000.0 grams of water and stir to form a slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com