Hollow calcium carbonate microsphere and preparation method thereof

A hollow microsphere, calcium carbonate technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of high additive content, serious product agglomeration, complicated operation, etc., and achieve high biocompatibility and biodegradability. The effect of uniform diameter distribution and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Use water as solvent to prepare 0.1mol / L Na 2 CO 3 solution, 0.1mol / L CaCl 2 solution, 0.5g / L PAA solution (the relative molecular weight of PAA is 2000) and 10.0mmol / L SDS solution. Take out two PAA (each 25mL) solution, add to 100mLNa respectively 2 CO 3 solution and 100mL CaCl 2 Solution, stirred for 0.5h. Add 50mL of SDS solution to the 2 CO 3 and a three-necked flask of a mixed solution of PAA, and then CaCl 2 The mixed solution with PAA was quickly added into the three-necked flask, and the reaction was maintained for 1 hour at 80° C. and a rotation speed of 200 r / min. The resulting CaCO 3 The suspension was filtered, washed three times with deionized water and absolute ethanol, and the filter cake was dried and dehydrated in a drying oven at 80° C. to obtain a white powder product.

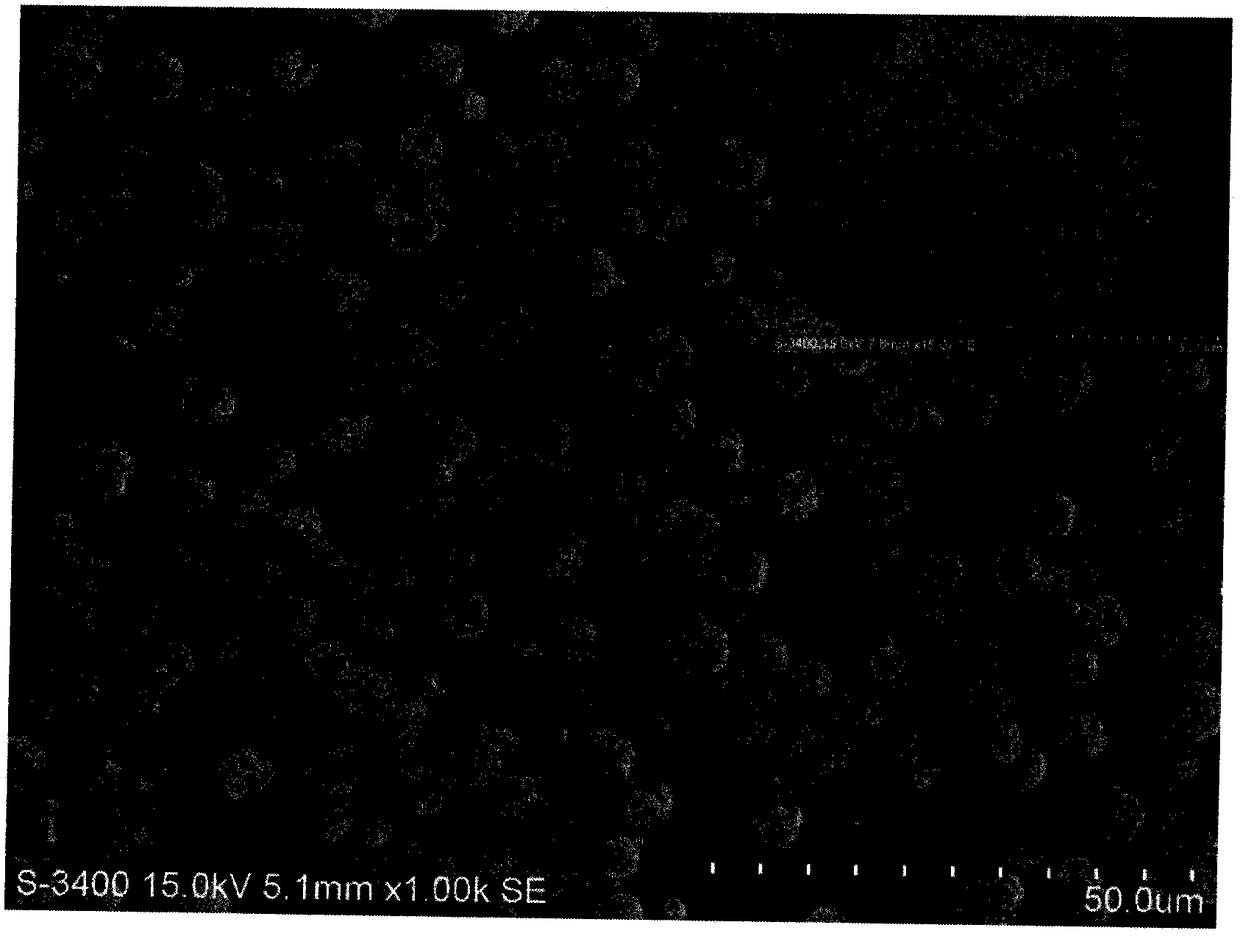

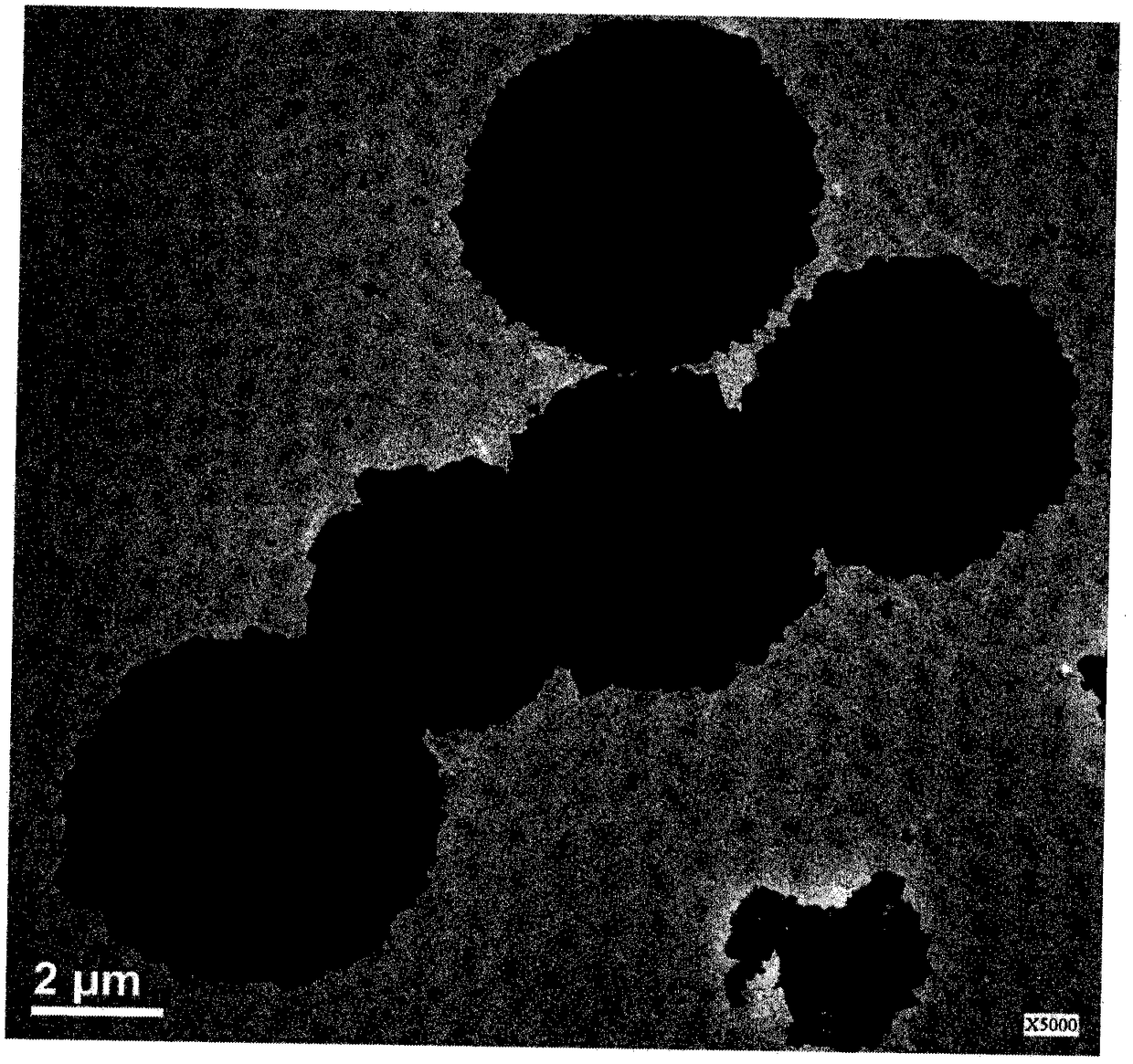

[0041] The SEM photo and TEM photo of the product are attached figure 1 And attached figure 2 , the average particle size is 6.2 μm, the molar content of its vaterite ca...

Embodiment 2

[0043] Use water as solvent to prepare 1.0mol / L Na 2 CO 3 Solution, 1.0mol / L CaCl 2 Solution, 1.0g / L PAA solution (the relative molecular weight of PAA is 5000) and 25.0mmol / L SDS solution. Two parts of PAA (each 25mL) solution were taken out and added to 100mL Na 2 CO 3 solution and 100mL CaCl 2 solution, 0.5h. Add 50mL of SDS solution to the 2 CO 3 and a three-necked flask of a mixed solution of PAA, and then CaCl 2 The mixed solution with PAA was quickly added into the three-necked flask, and the reaction was maintained for 1 hour at 90°C and the rotation speed was 200r / min. The resulting CaCO 3 The suspension was filtered, washed three times with deionized water and absolute ethanol, and the filter cake was dried and dehydrated in a drying oven at 80° C. to obtain a white powdery product.

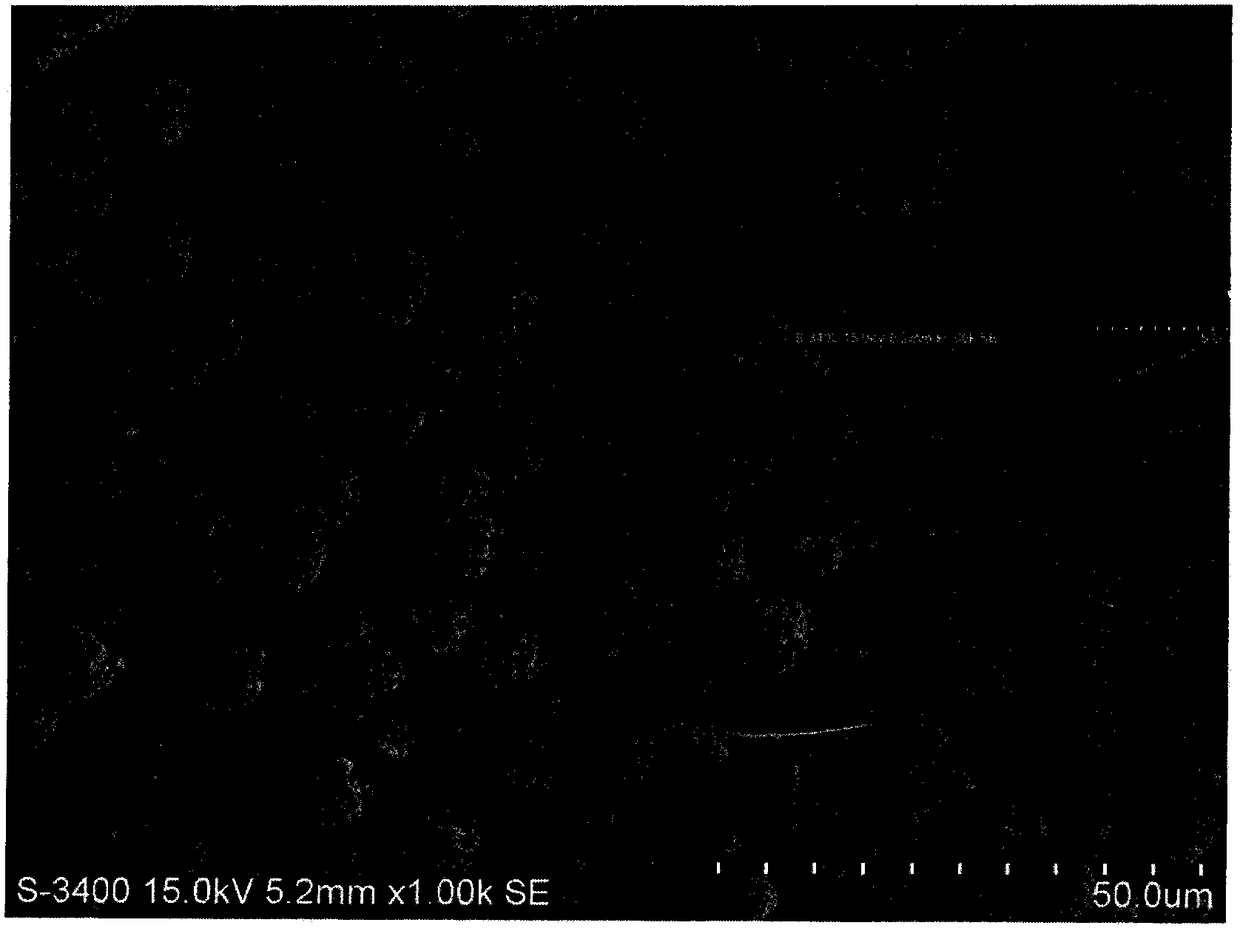

[0044] The SEM photo of the product is attached image 3 , with an average particle size of 6.8 μm, see the attached XRD pattern Figure 4 , the molar content of vaterite ca...

Embodiment 3

[0046] According to the same method as in Example 1, the difference is: Na 2 CO 3 The solution concentration is 0.5mol / L; CaCl 2 The solution concentration is 0.5mol / L; the molecular weight of PAA is 3000, and its concentration is 0.8g / L; the concentration of SDS is 15.0mmol / L; the reaction temperature is 60°C.

[0047] The SEM photo of the product is attached Figure 5 , with an average particle size of 5.2 μm, see the attached XRD pattern Figure 6 , its vaterite calcium carbonate molar content is 46.8% (calcite calcium carbonate molar content is 53.2%), and its specific surface area is 40.6m 2 / g, and the average pore diameter is 18.49nm, showing that the product is a calcium carbonate hollow microsphere with a large specific surface area. Other test and calculation data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com