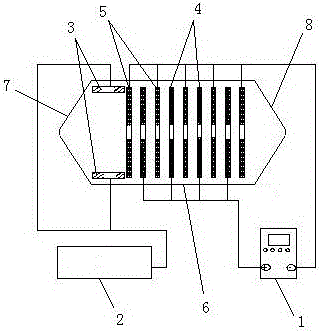

Electroacoustic multivariant catalytic oxidation device and method for treating wastewater by using same

A technology of electrocatalytic oxidation and catalytic oxidation, applied in chemical instruments and methods, water treatment of special compounds, water/sewage treatment, etc., can solve unfavorable industrial scale expansion and application promotion, limited reference significance of industrial treatment, and limited waste water contact Problems such as contact area, to achieve the effect of improving oxidation degradation efficiency, good market application prospects, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

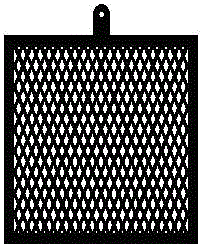

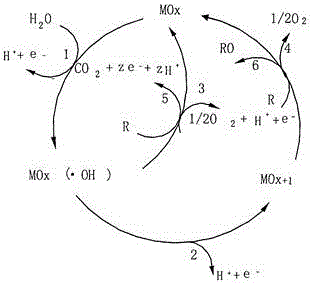

Method used

Image

Examples

Embodiment 1

[0063] Taking the concentrated water of RO membrane system of a printing and dyeing enterprise as the wastewater to be treated, the ultrasonic power is 600W, and the frequency is 25kHz; the electrocatalytic oxidation uses stainless steel and cerium-doped lead oxide coated titanium anode as cathode and anode respectively, and the distance between cathode and anode is 25mm. The current density is 10mA / cm 2 , flow rate 3cm / min, continuous operation.

[0064] Water quality comparison table before and after wastewater treatment

[0065]

Embodiment 2

[0067] Taking the wastewater from a chemical production enterprise as the wastewater to be treated, the ultrasonic power is 800W, and the frequency is 40kHz; the electrocatalytic oxidation uses titanium and ruthenium-based composite oxide-coated titanium anodes as the cathode and anode respectively, the distance between the cathode and the anode is 25mm, and the treatment current density is 12mA / cm 2 , flow rate 1cm / min, continuous operation.

[0068] Water quality comparison table before and after wastewater treatment

[0069]

[0070] To sum up, a kind of acoustic-electric multi-component catalytic oxidation device and its method for treating wastewater according to the present invention have improved the oxidative degradation efficiency of pollutants by single electrocatalytic oxidation technology, have wide applicability, and do not add It is an efficient "green" water treatment technology, which can effectively reduce COD in wastewater, and can be used as biochemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com