Catalyst for heterogeneous Fenton reaction

A Fenton reaction and catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of easy dissolution and loss of iron, complicated preparation process and high cost problem, to achieve the effect of easy recovery, high catalytic activity and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 1mmol of ferric nitrate in 10mL of water, then add 10mmol of sodium hydroxide, stir for 30 minutes and centrifuge, and dissolve the separated solid in a mixture of 70ml of ethanol and water (ethanol / water=4 / 3, volume ratio) , then add 0.1mmol cetyltrimethylammonium bromide, then add 4mmol ethyl orthosilicate, stir at 25°C for 6 hours, then centrifuge to collect the solid, dry at 80°C and then bake at 450°C for 5 hours.

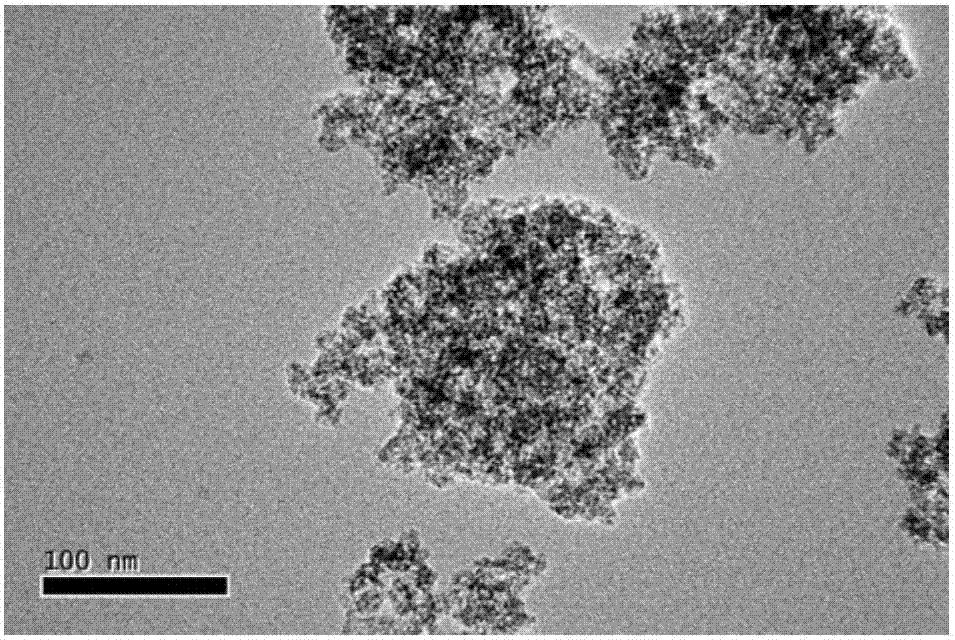

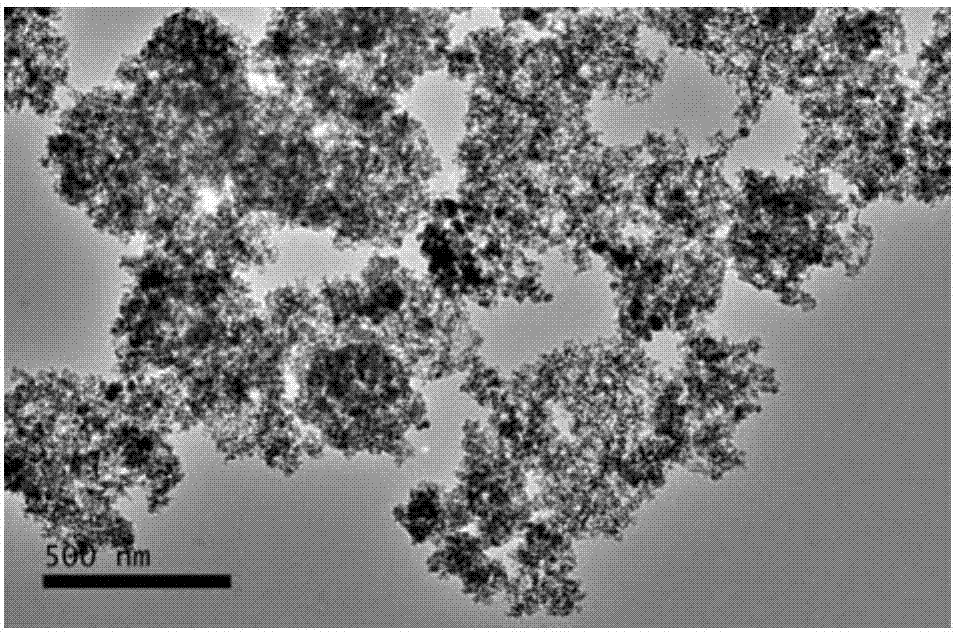

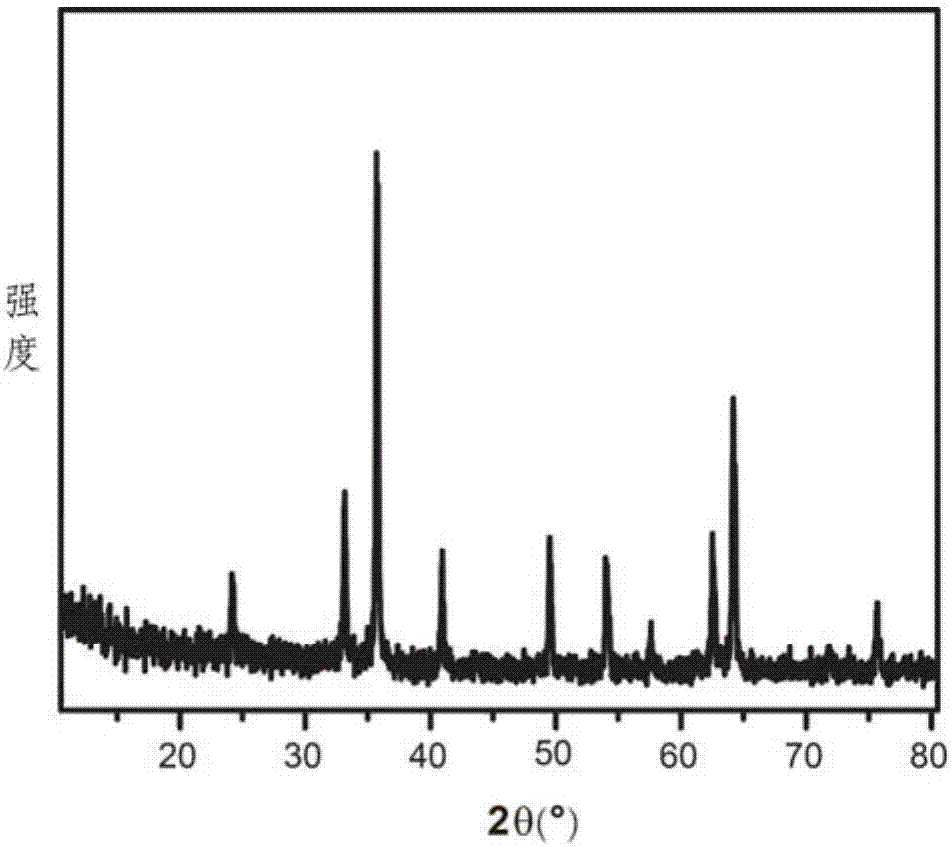

[0029] Such as figure 1 As shown, before firing, the iron oxide and silicon oxide particles are both nanoscale particles, and the silicon oxide nanoscale particles are coated on the outside of the iron oxide nanoscale particles. After firing, it can be seen that silicon oxide is still coated on the outside of iron oxide, which can effectively prevent the dissolution of internal iron, such as figure 2 shown. image 3 It is an X-ray diffraction photo of the catalyst of the present invention after calcination, it can be seen that iron oxide and...

Embodiment 2

[0031] Dissolve 1mmol ferric chloride in 100mL water, then add 3mmol sodium hydroxide, centrifuge after stirring for 5 minutes, dissolve the solid obtained by separation in the mixed solution of 10ml ethanol and water (ethanol / water=5 / 1, volume ratio ), then add 0.02mmol cetyltrimethylammonium bromide, then add 0.44mmol tetraethyl orthosilicate, stir at 20°C for 10 hours, then centrifuge to collect the solid, dry at 50°C and then roast at 350°C for 15 Hour.

Embodiment 3

[0033] Dissolve 1mmol ferric sulfate in 50mL water, then add 8mmol potassium hydroxide, centrifuge after stirring for 60 minutes, dissolve the separated solid in a mixed solution of 100ml ethanol and water (ethanol / water=1 / 5, volume ratio) , then add 0.04mmol cetyltrimethylammonium bromide, then add 7.5mmol tetraethyl orthosilicate, stir at 40°C for 3 hours, then centrifuge to collect the solid, dry at 200°C and then bake at 800°C for 2 hours .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com