Dendrobium small molecule peptide and preparation method thereof

A technology for small molecule peptides and dendrobium, which is applied in complex biological enzyme digestion and biochemical separation process, small molecule peptides of dendrobium and its application fields, can solve the problems of complicated post-processing steps, unfavorable mass production, increased process time, etc., and saves money Enzymatic hydrolysis time, easy cleaning and regeneration, reduction of ash and salt generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

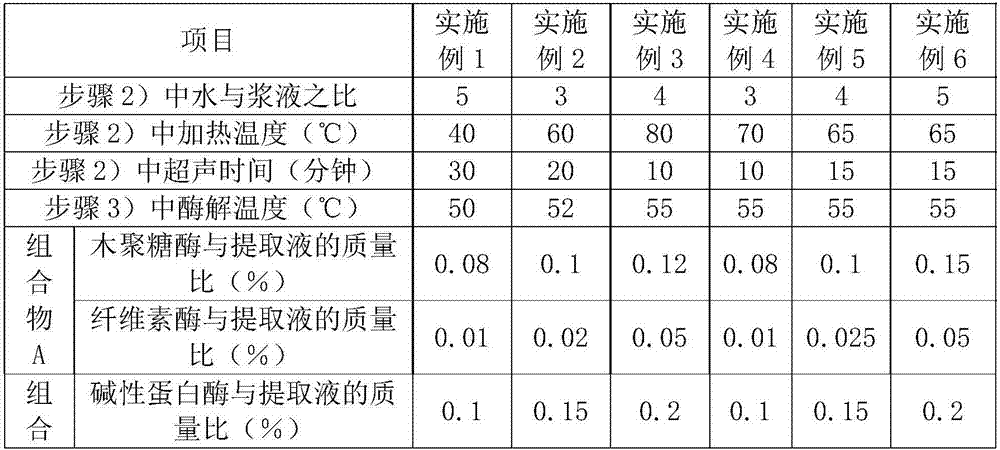

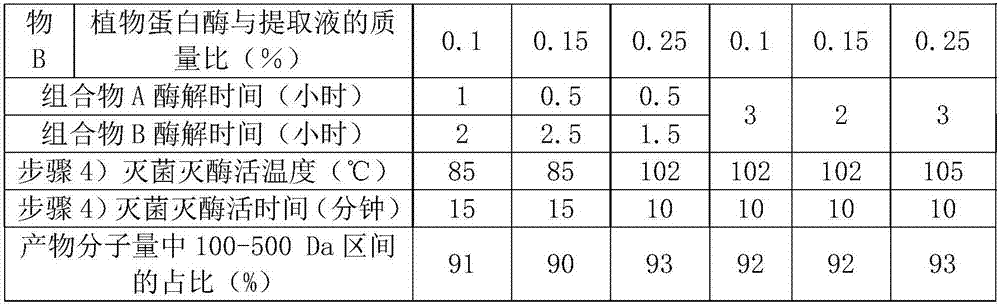

Embodiment 1

[0030] The preparation method of the dendrobium small molecular peptide is to obtain the dendrobium small molecular peptide product through pretreatment, extraction, enzymolysis, separation and purification, concentration, drying and refining.

[0031] 1) Fresh Dendrobium nobile is crushed and refined to obtain a slurry;

[0032] 2) Adding water with a mass 5 times the mass of the slurry, heating to 40°C, and ultrasonically extracting for 30 minutes with an ultrasonic power of 30kW to obtain an extract;

[0033] 3) Heat the extract to 50°C, first add 0.08% xylanase and 0.01% cellulase in a mass ratio to the extract to hydrolyze for 1 hour, then add 0.1 mass ratio to the extract The alkaline protease of %, the plant protease of 0.1% carry out secondary enzymolysis, and enzymolysis time is 2 hours; Described plant protease is made of papain, bromelain and actinidia protease, and the mass ratio of three kinds of enzymes is 4:3: 3.

[0034] 4) Heat the enzymolysis solution to 85...

Embodiment 2

[0039] The preparation method of the dendrobium small molecular peptide is to obtain the dendrobium small molecular peptide product through pretreatment, extraction, enzymolysis, separation and purification, concentration and drying.

[0040] 1) Fresh Dendrobium nobile is crushed and refined to obtain a slurry;

[0041] 2) Add water with a mass three times the mass of the slurry, heat to 60°C, perform ultrasonic extraction for 20 minutes, and the ultrasonic power is 30kW to obtain an extract;

[0042] 3) Warm the extract to 52°C, first add 0.1% xylanase and 0.02% cellulase in a mass ratio to the extract for 0.5 hours, and then add a mass ratio of 0.15 to the extract The alkaline protease of %, the plant protease of 0.15% carry out secondary enzymolysis, and enzymolysis time is 2.5 hours; Described plant protease is made of papain, bromelain and actinidia protease, and the mass ratio of three kinds of enzymes is 4:3: 3.

[0043] 4) Heating the enzymolysis solution to 85°C for...

Embodiment 3

[0048] The preparation method of the dendrobium small molecular peptide is to obtain the dendrobium small molecular peptide product through pretreatment, extraction, enzymolysis, separation and purification, concentration and drying.

[0049] 1) Fresh Dendrobium nobile is crushed and refined to obtain a slurry;

[0050] 2) adding water with a mass 4 times the mass of the slurry, heating to 80°C, and ultrasonically extracting for 10 minutes with an ultrasonic power of 30kW to obtain an extract;

[0051] 3) Heat the extract to 55°C, first add 0.12% xylanase and 0.05% cellulase to react for 0.5 hours in mass ratio to the extract, and then add 0.2% mass ratio to the extract The alkaline protease of %, the plant protease of 0.25% carry out secondary enzymolysis, and enzymolysis time is 1.5 hours; Described plant protease is made of papain, bromelain and actinidia protease, and the mass ratio of three kinds of enzymes is 4:3: 3.

[0052] 4) Heating the enzymolysis solution to 102° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com