Preparation method and application of pea protein peptide

A technology of pea protein peptides and production methods, which is applied in the fields of application, protein food processing, plant protein processing, etc., to achieve the effects of strong unevenness, increased proportion, and shortened enzymatic hydrolysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The pea protein powder with a water content of 20% was extruded under the conditions of barrel temperature 60°C, screw speed 170 r / min, and membrane pore diameter 12 mm. The extruded product is cooled and crushed to 40 mesh".

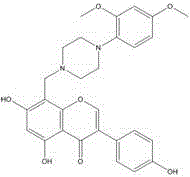

[0026] Dissolve the extruded pea protein powder in a phosphate buffer solution with a pH value of 6.5 to form a dispersion with a mass concentration of 7% of the pea protein powder, add neutral protease accounting for 12% of the mass of the pea protein powder, and simultaneously add 2% by mass of neutral protease promoter 8–((4–(2,4–dimethoxyphenyl)piperazin–1–yl)methyl)–5,7–dihydroxy–3–(4– Hydroxyphenyl)-4H-benzopyran-4-one, at a pH value of 6.5 and a temperature of 65°C, the enzymatic hydrolysis was performed for 1.5 hours with shaking in a water bath. After the end of the enzymatic hydrolysis, the enzymatic solution was maintained at 100°C for 5 minutes to inactivate , then cooled to room temperature, and filtered to obtain pea polypeptide li...

Embodiment 2

[0029] The pea protein powder with a water content of 25% was extruded under the conditions of barrel temperature 60°C, screw speed 170 r / min, and membrane pore diameter 12 mm. The extruded product is cooled and crushed to 40 mesh".

[0030] Dissolve the pea protein powder in a phosphate buffer solution with a pH value of 6.3 to form a dispersion with a mass concentration of 7% of the pea protein powder, add 10% of the mass of the pea protein powder, and add 4 % neutral protease promoter 8–((4–(2,4–dimethoxyphenyl)piperazin–1–yl)methyl)–5,7–dihydroxy–3–(4–hydroxyphenyl base) –4H-benzopyran-4-one, at a pH of 6.3 and a temperature of 60°C, the enzymolysis was carried out for 2.5 hours with shaking in a water bath. Cool to room temperature and filter to obtain pea polypeptide liquid. Under the same enzymatic hydrolysis time and adding neutral protease accelerator, the enzymatic hydrolysis degree of extruded pea protein was 28.3% higher than that of unextruded pea protein; When...

Embodiment 3

[0033] The pea protein powder with a water content of 40% was extruded under the conditions of barrel temperature 60°C, screw speed 170 r / min, and membrane pore diameter 12 mm. The extruded product is cooled and crushed to 40 mesh".

[0034]Dissolve pea protein powder in a phosphate buffer solution with a pH value of 6.4 to form a dispersion with a mass concentration of 7% pea protein powder, add neutral protease accounting for 11% of the mass of pea protein powder, and add 3% neutral protease % neutral protease promoter 8–((4–(2,4–dimethoxyphenyl)piperazin–1–yl)methyl)–5,7–dihydroxy–3–(4–hydroxyphenyl base) –4H-benzopyran-4-one, at a pH of 6.4 and a temperature of 63°C, the enzymolysis solution was shaken in a water bath for 2 hours. After the end of the enzymolysis, the enzymolysis solution was maintained at 95°C for 10 minutes to inactivate the enzyme, and then cooled to room temperature, and filtered to obtain pea polypeptide liquid. Under the same enzymatic hydrolysis t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com