Method for preparing silkworm chrysalis source ACE (Angiotensin Converting Enzyme) inhibitory peptide by ultrasonic-ionic liquid coupling technology

A technology of ionic liquids and ultrasound, applied in the field of bioengineering, can solve the problems of preparing silkworm chrysalis-derived ACE inhibitory peptides, and achieve the effects of shortened enzymatic hydrolysis time, low raw material prices, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

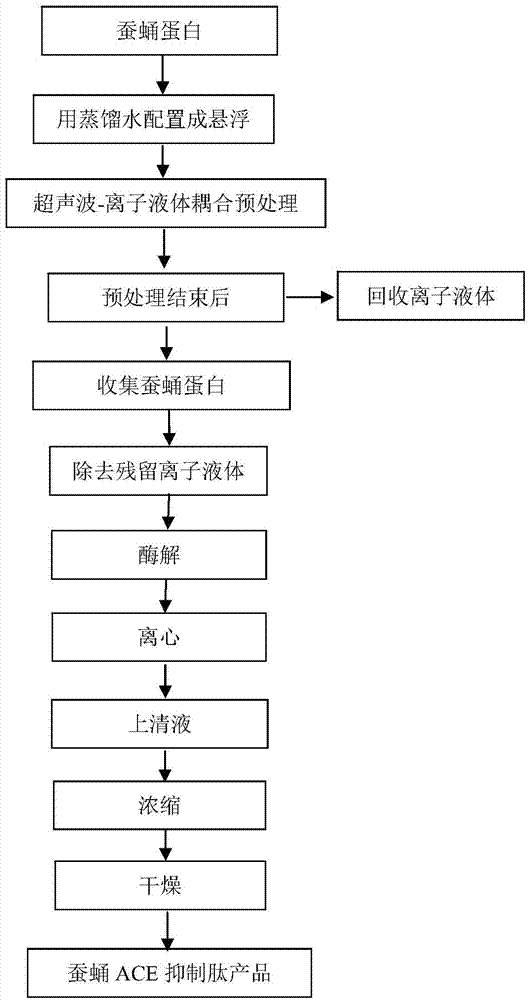

Image

Examples

Embodiment 1

[0024]According to the ratio of liquid to material 20mL / g, the silkworm chrysalis protein was prepared into a suspension with distilled water, and then mixed with an equal volume of ionic liquid and added to the beaker. The 24kHz ultrasonic probe was immersed in the water phase, and the ultrasonic wave was turned on. The pretreatment temperature was controlled at 25°C. The ultrasonic intermittent ratio is 1:1, the ultrasonic power is 300W, and the pretreatment time is 20min. After the pretreatment, centrifuge to collect the silkworm pupae protein and recover the ionic liquid. The collected silkworm pupae protein is washed with distilled water and centrifuged until the residual ionic liquid is removed. , the pretreated silkworm chrysalis protein was prepared into a solution with a substrate concentration of 1.0% (w / v, g / mL) with distilled water, under the conditions of enzymolysis temperature 45°C, enzymolysis pH 8.0, and enzyme addition 2000U / g Hydrolyze with alkaline protease ...

Embodiment 2

[0026] According to the ratio of liquid to material of 27mL / g, the silkworm chrysalis protein was prepared into a suspension with distilled water, and then mixed with an equal volume of ionic liquid and added to the beaker. The 24kHz ultrasonic probe was immersed in the water phase, and the ultrasonic wave was turned on. The pretreatment temperature was controlled at 30°C. The ultrasonic intermittent ratio is 1:1, the ultrasonic power is 406W, and the pretreatment time is 32min. After the pretreatment, centrifuge to collect silkworm chrysalis protein and recover the ionic liquid. The collected silkworm chrysalis protein is washed with distilled water and centrifuged until the residual ionic liquid is removed. , the pretreated silkworm chrysalis protein was prepared into a solution with a substrate concentration of 2.5% (w / v, g / mL) with distilled water, under the conditions of enzymolysis temperature 50°C, enzymolysis pH 8.5, and enzyme addition 3000U / g Hydrolyze with alkaline p...

Embodiment 3

[0028] According to the ratio of liquid to material 40mL / g, the silkworm chrysalis protein was prepared into a suspension with distilled water, and then mixed with an equal volume of ionic liquid and added to the beaker. The 24kHz ultrasonic probe was immersed in the water phase, and the ultrasonic wave was turned on. The pretreatment temperature was controlled at 35°C. The ultrasonic intermittent ratio is 1:1, the ultrasonic power is 500W, and the pretreatment time is 40min. After the pretreatment, centrifuge to collect silkworm chrysalis protein and recover the ionic liquid. The collected silkworm chrysalis protein is washed with distilled water and centrifuged until the residual ionic liquid is removed. , the pretreated silkworm chrysalis protein was prepared into a solution with a substrate concentration of 5.0% (w / v, g / mL) with distilled water, under the conditions of enzymolysis temperature 55°C, enzymolysis pH 9.0, and enzyme addition 4000U / g Hydrolyze with alkaline prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com