Pesticide microcapsule granule and preparation method thereof

A technology of microcapsule granules and microcapsules, applied in botany equipment and methods, biocides, animal repellents, etc., can solve the problems of high cost of polyurethane and gelatin-gum arabic, low storage stability and suspension rate of suspensions , complex operation of the preparation method, etc., to achieve the effects of low cost, easy control of the process, and high content of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Dissolving 8.0 parts by mass of chlorpyrifos in 2.0 parts by mass of xylene, then adding it to 100 parts by mass of 5.0% gelatin solution, and stirring at a speed of 1200 r / min for 20 minutes at 30-40° C. to form a uniform emulsion;

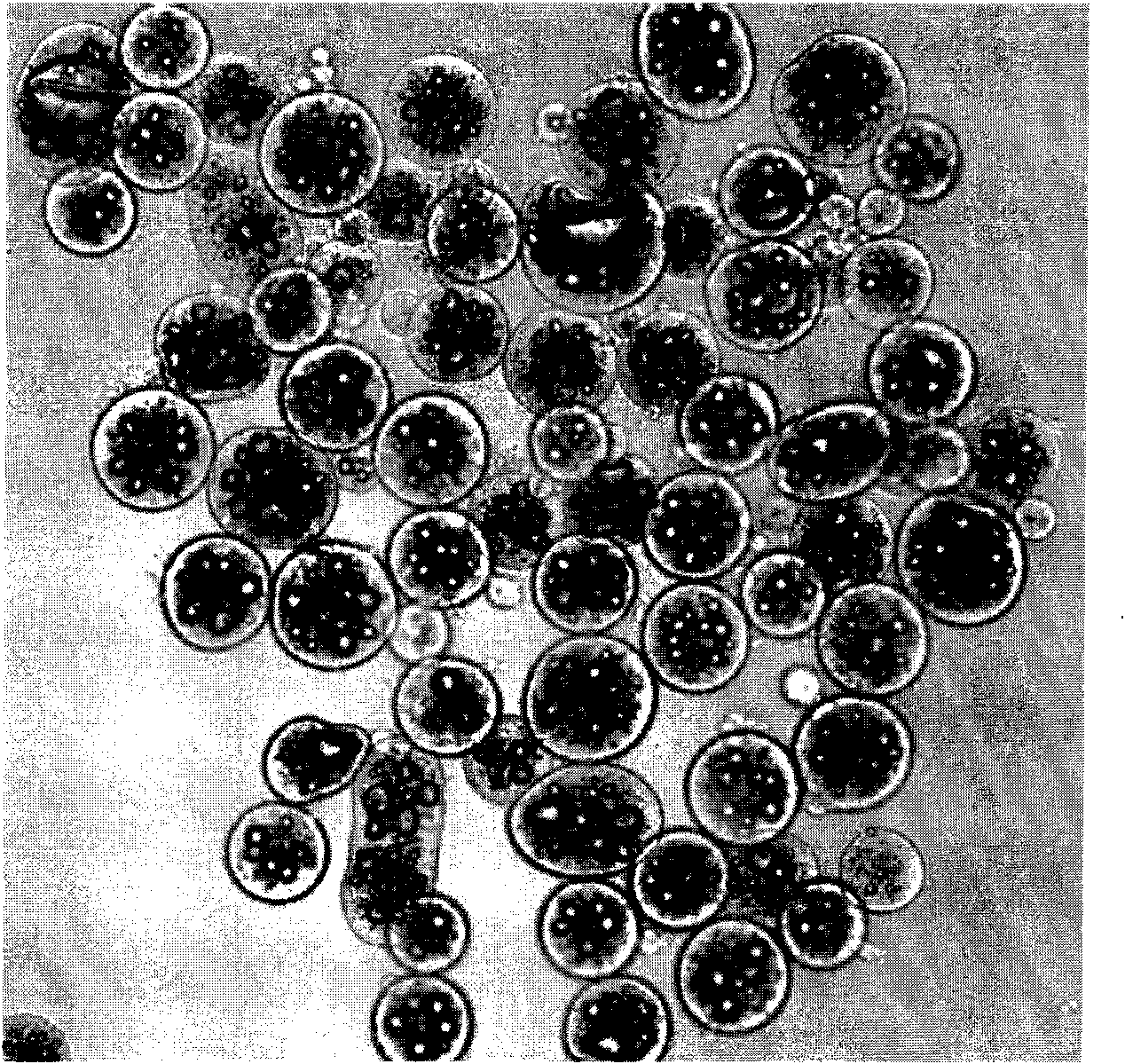

[0028] (2) Stir at a rotation speed of 600 rpm, add a mixed flocculant containing 15% sodium sulfate and 5% ammonium sulfate to the above emulsion, add 10 parts by mass every 5 minutes, and add 100 parts by mass in total. After the encapsulation, add 2.5 parts by mass of white carbon black, and continue to stir for 30 minutes. During the encapsulation process, n-butanol can be added dropwise as a defoamer for defoaming. Keep stirring and maintain the temperature at 30-40°C during the encapsulation process. Microcapsule particles with a diameter of about 60 μm can be obtained;

[0029] (3) Place the microcapsules in ice water for cooling, and stir at 150rpm until the microcapsules are completely condensed;

[0030] (4) Adding glutarald...

Embodiment 2

[0034] (1) Dissolve 3.0 parts by mass of deltamethrin in 4.0 parts by mass of cyclohexanone, 3.0 parts by mass of xylene and 0.5 parts by mass of acetone, then add it to 100 parts by mass of 5.0% gelatin solution, at 30-40°C Stir at a speed of 1200rpm for 20min to form a uniform emulsion;

[0035] (2) Stir at a rotation speed of 600 rpm, add a mixed flocculant containing 15% sodium sulfate and 5% ammonium sulfate to the above emulsion, add 10 parts by mass every 5 minutes, and add 100 parts by mass in total. After the encapsulation, add 2.5 parts by mass of white carbon black, and continue to stir for 30 minutes. During the encapsulation process, n-butanol can be added dropwise as a defoamer for defoaming. Keep stirring and maintain the temperature at 30-40°C during the encapsulation process. Microcapsule particles with a diameter of about 60 μm can be obtained;

[0036] (3) Place the microcapsules in ice water for cooling, and stir at 150rpm until the microcapsules are compl...

Embodiment 3

[0041] (1) 5.0 parts by mass of chlorpyrifos were dissolved in 5.0 parts by mass of isoamyl alcohol, then added to 100 parts by mass of 5.0% gelatin solution, and stirred at 30-40° C. for 20 minutes at a speed of 1200 rpm to form a uniform emulsion;

[0042] (2) Stir at a rotation speed of 600 rpm, add a mixed flocculant containing 15% sodium sulfate and 5% ammonium sulfate to the above emulsion, add 10 parts by mass every 5 minutes, and add 80 parts by mass in total. Then add 1.5 parts by mass of white carbon black, and then add 20 parts by mass of a mixed flocculant containing 15% sodium sulfate and 5% ammonium sulfate. After the encapsulation, add 1.5 parts by mass of white carbon black, and continue to stir for 30 minutes. During the encapsulation process, n-butanol can be added dropwise as a defoamer for defoaming. Keep stirring and maintain the temperature at 30-40°C during the entire process. Microcapsule particles with a diameter of about 60 μm can be obtained;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com