Method for flotation of uranium minerals from volcanic rock type uranium ores

A technology of uranium ore and volcanic rock, which is applied in the field of mineral processing, can solve the problems of reducing the processing capacity of hydrometallurgy ore, reducing production costs, and high production costs, and achieves the effects of improving flotation recovery, reducing production costs, and reducing acid-consuming minerals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

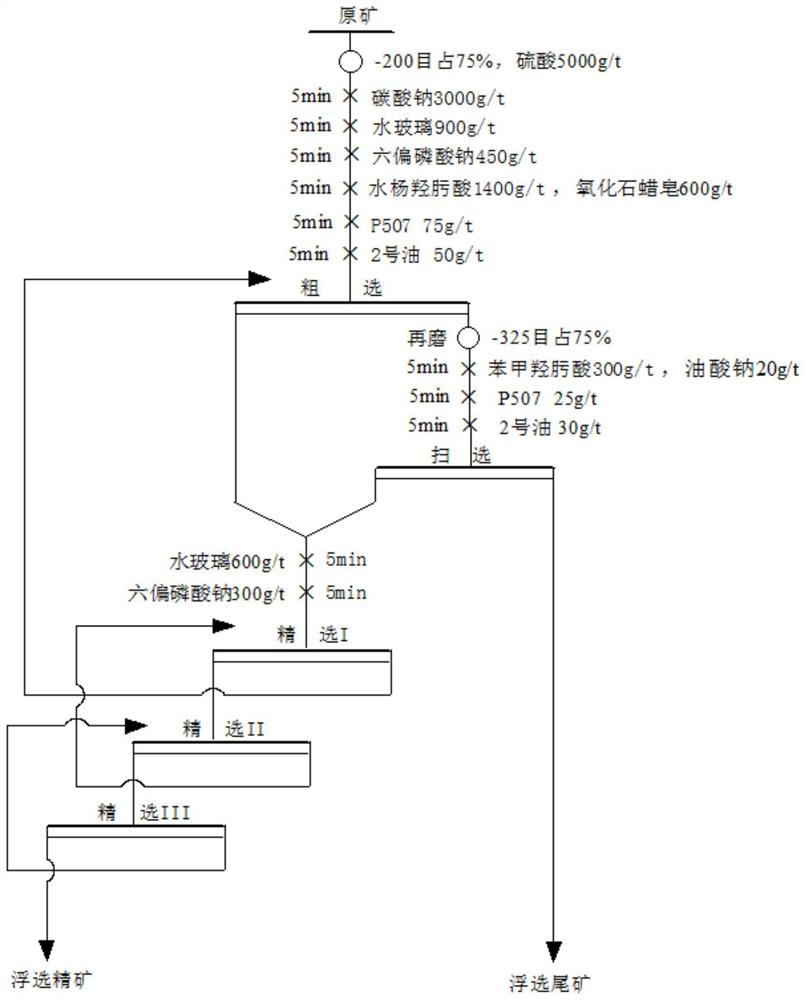

Method used

Image

Examples

Embodiment 1

[0037] A volcanic uranium ore is mainly composed of muscovite, quartz, calcite, epidote, rutile, fluorite, apatite, zircon, pitchblende, uranite, pyrite, rutile, sphalerite, ferro-titanium ore, colloidal molybdenum ore, galena, magnetite, uranium, etc. There are many minerals such as calcite and fluorite in the ore, which leads to a large amount of acid consumption during the leaching of the ore. Uranium mainly exists in the form of independent uranium minerals, including uranite, pitchblende, and uranite, and a small amount exists in uranium thorite in the form of isomorphism. The grade of uranium in the ore is 0.23%.

[0038](1) Break the ore particle size to -5mm, add 2000g / t of sulfuric acid during grinding, grind the ore until the fineness -200 mesh accounts for 55%, adjust the pulp concentration to 20%, and transfer it to the flotation tank, The pulp temperature was adjusted to 20°C.

[0039] (2) Add 3000g / t of sodium carbonate to the pulp, and stir for 15min under th...

example 1

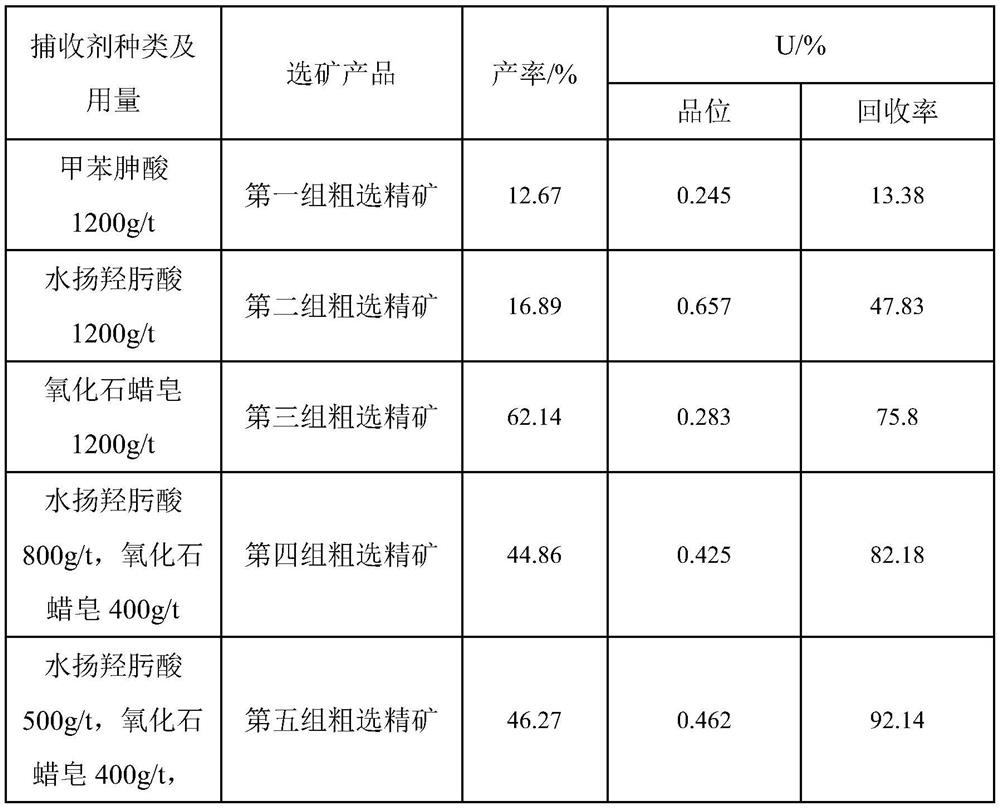

[0041] Example 1 test results are shown in Table 1.

[0042] Table 1 Example 1 test results

[0043]

[0044]

[0045] It can be seen from Table 1 that the combined use of salicylic hydroxamic acid and oxidized paraffin wax soap can play a synergistic effect, and the limited flotation of uranium minerals in the ore can be carried out. In addition, the addition of auxiliary collector P507 can enhance the collection capacity of uranium minerals and improve the uranium minerals. The recovery rate, and reduce the amount of salicylhydroxamic acid.

Embodiment 2

[0047] A volcanic uranium ore is mainly composed of muscovite, quartz, calcite, epidote, rutile, fluorite, apatite, zircon, pitchblende, uranite, pyrite, rutile, sphalerite, ferro-titanium ore, colloidal molybdenum ore, galena, magnetite, uranium, etc. There are many minerals such as calcite and fluorite in the ore, which leads to a large amount of acid consumption during the leaching of the ore. Uranium mainly exists in the form of independent uranium minerals, including uranite, pitchblende, and uranite, and a small amount exists in uranium thorite in the form of isomorphism. The grade of uranium in the ore is 0.23%.

[0048] (1) Crush the ore particle size to -4mm, add 3000g / t of sulfuric acid during grinding, grind the ore until the fineness -200 mesh accounts for 70%, adjust the pulp concentration to 25%, and transfer it to the flotation tank, The slurry temperature was adjusted to 30°C.

[0049] (2) Inhibitor comparison test, a total of 4 groups of experiments were se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com