Ship tail gas denitrification process and system, desulfurization and denitrification integrated process and system

A technology for ship exhaust, desulfurization and denitrification, which is applied in the field of desulfurization and denitrification integrated process and system, and the field of ship exhaust denitrification process and system, can solve the problems that desulfurization, desulfurization and denitrification are difficult to be effectively connected and energy consumption is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

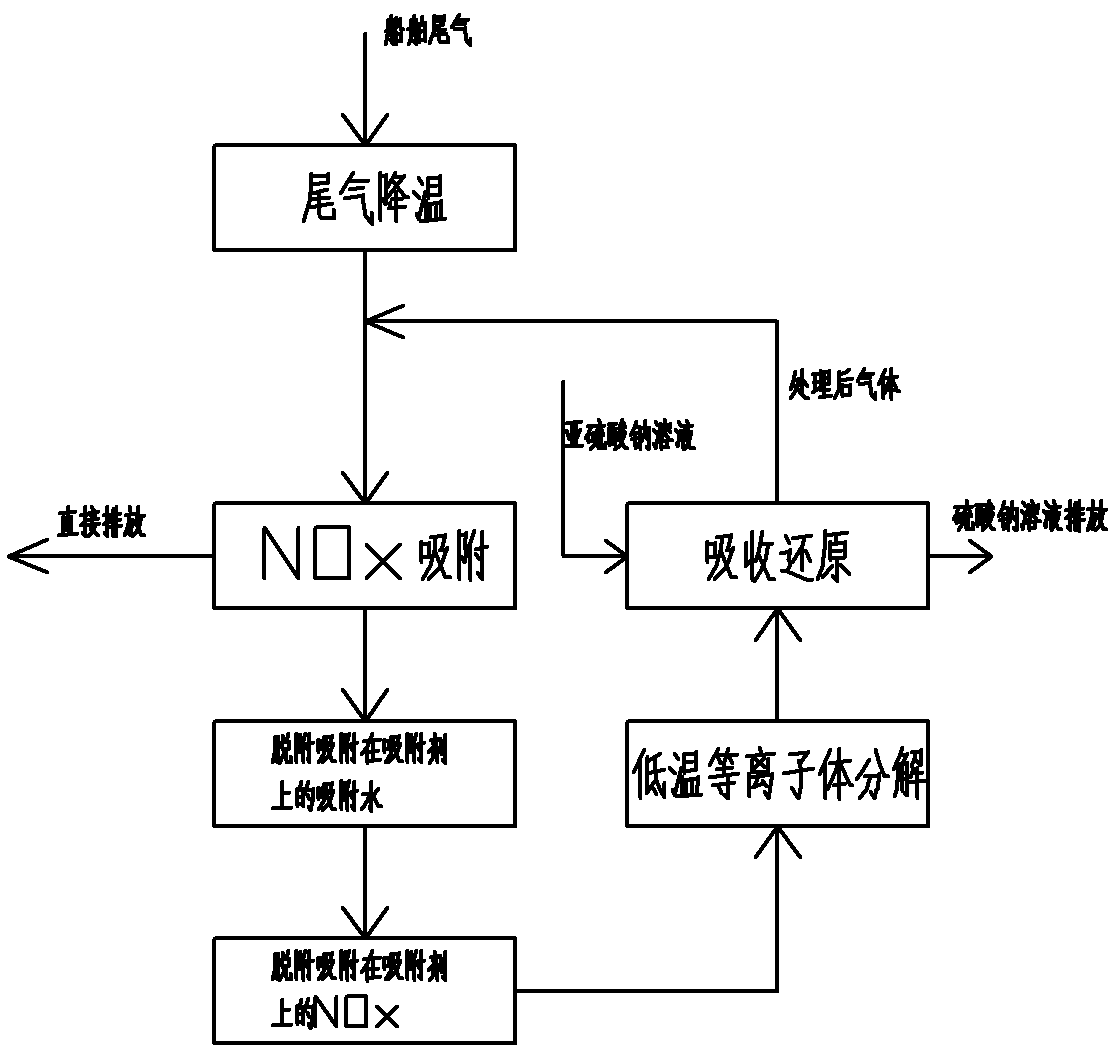

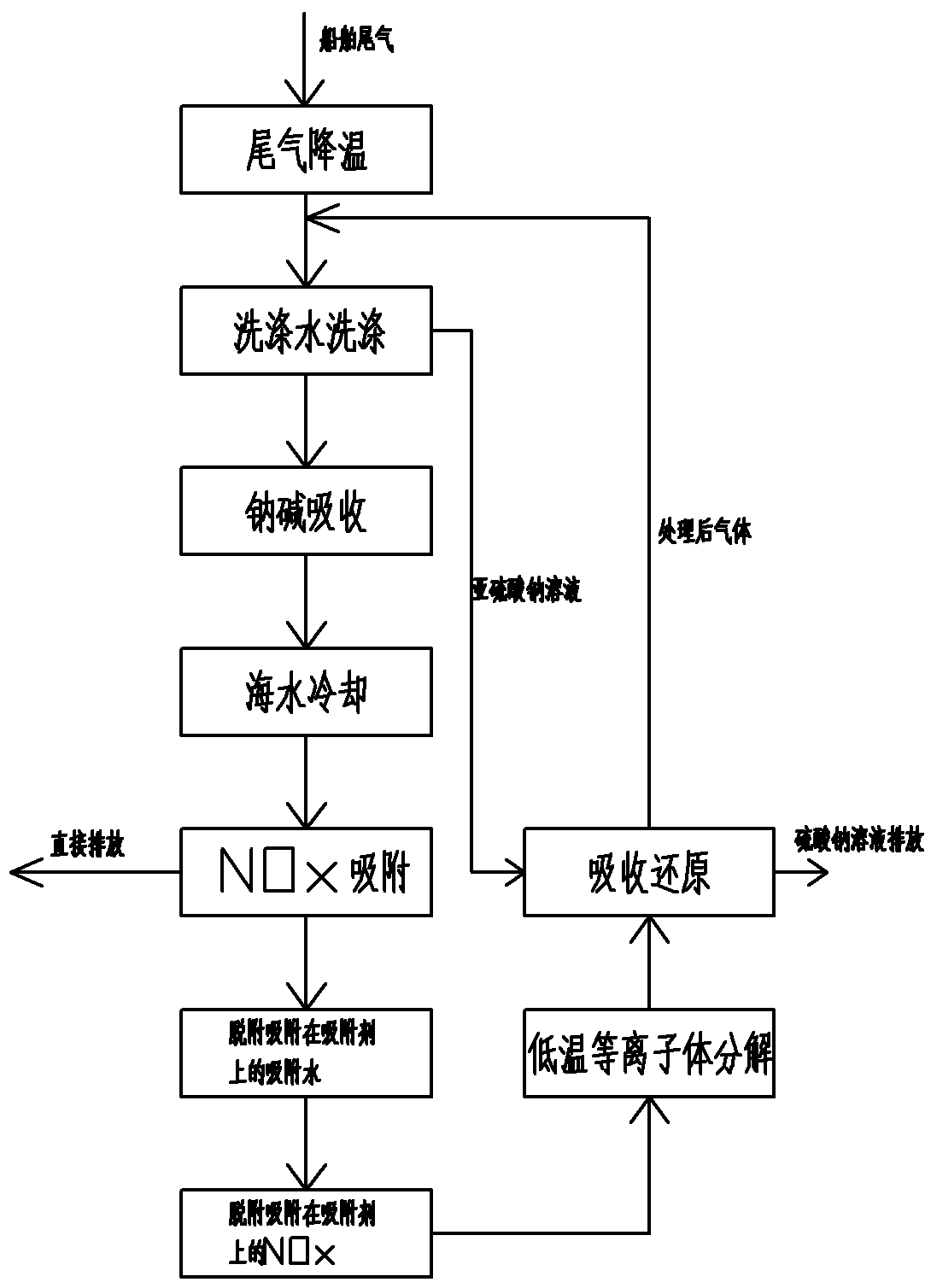

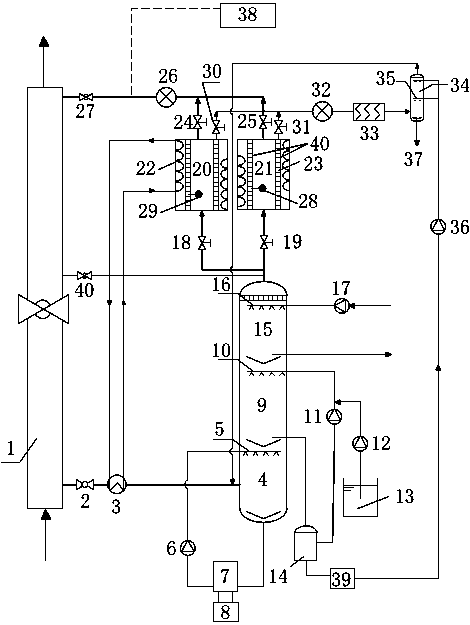

[0066] See figure 1 As shown, the ship tail gas denitrification process includes the following steps:

[0067] (1) Exhaust gas cooling

[0068] The exhaust gas discharged from the ship is cooled by the oil-gas heat exchanger;

[0069] (2) Seawater cooling

[0070] After the oil-gas heat exchange, the ship exhaust gas enters the seawater cooling tower, and sprays seawater into the seawater cooling tower to further cool the ship exhaust gas;

[0071] (3) NO X adsorption

[0072] Here we take two adsorption towers as an example. When there are three or more, it is similar to two. The ship exhaust gas enters one adsorption tower, and the NO in the ship exhaust gas X Adsorbed by the adsorbent in the adsorption tower for a long time, the NO in the exhaust gas X Adsorbed by the adsorbent in the tower for a long time, adsorbing NO X The final purified exhaust gas is discharged through the exhaust pipe, when NO is detected at the end of the exhaust pipe X When the breakthrough ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com