Method for separating and enriching chlorogenic acid in tobacco

A technology for separation and enrichment of chlorogenic acid, applied in chemical instruments and methods, preparation of carboxylic acid esters, preparation of organic compounds, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The invention is used to extract, separate and enrich the chlorogenic acid in tobacco leaves.

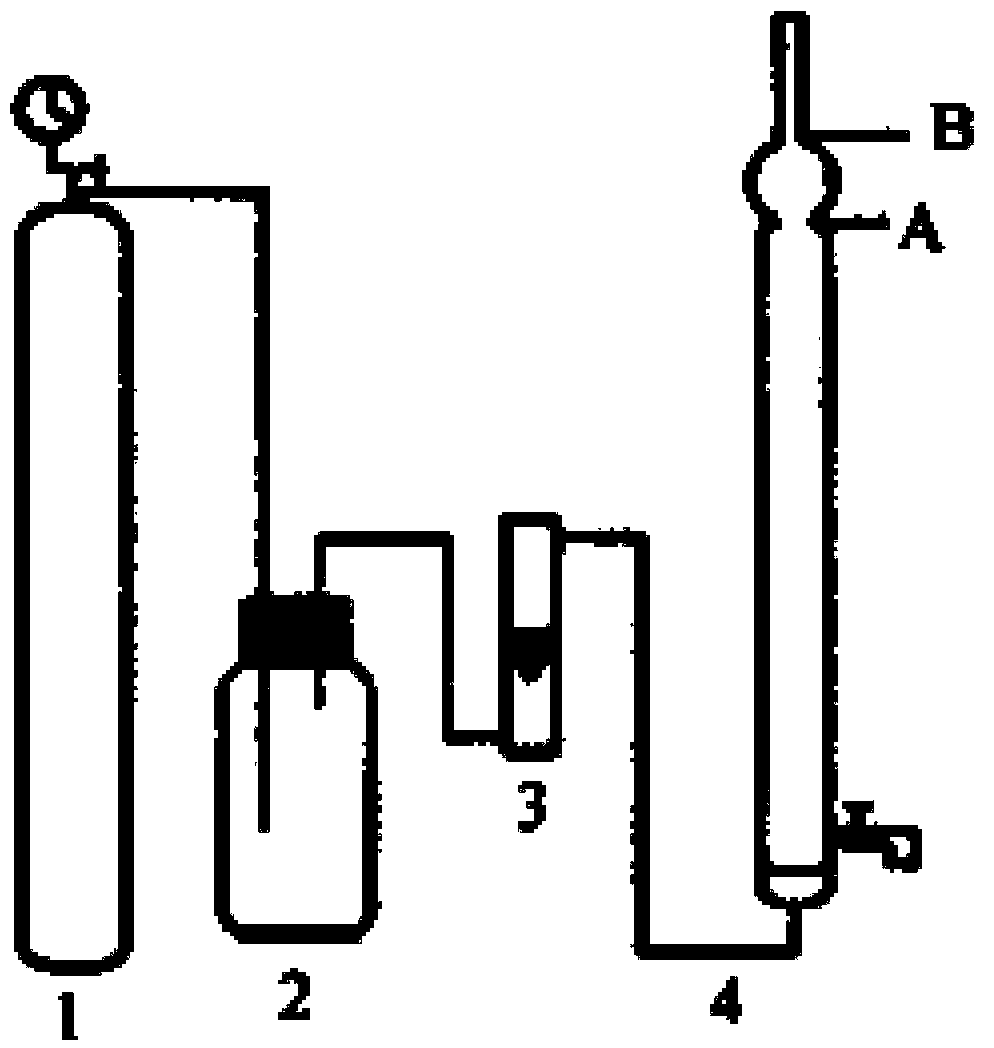

[0027] Take 10g of tobacco leaves crushed to 40 mesh, add 150mL of water, adjust the pH value to 3 with hydrochloric acid, and extract at 50°C for 3 hours; separate the tobacco extract with a conventional centrifuge, put 110mL of the extract into a self-made flotation cell, Add 10 mL of n-octanol and 1 mL of pyrogallol methanol solution as a mixed extraction solvent, pass through nitrogen flotation at a flow rate of 50 mL / min, and perform flotation for 40 minutes. The extractant from the upper layer is the concentrated solution containing chlorogenic acid. After HPLC detection, the calculated content of chlorogenic acid in the tobacco leaves is 1.55%.

Embodiment 2

[0029] The invention is used to extract, separate and enrich the chlorogenic acid in the tobacco dust.

[0030] Take 10g of tobacco powder, add 200mL of water, adjust the pH value to 5 with hydrochloric acid, extract at 60°C for 4 hours; separate the tobacco extract with a conventional centrifuge, put 150mL of the extract into a self-made flotation cell, add n-hexanol 2.5mL and 0.5mL of acetonitrile mixed extraction solvent, pass nitrogen flotation at a flow rate of 90mL / min, flotation for 20min, after the end, stand still for 20min, until there are no microbubbles in the flotation cell, separate the upper layer extractant, which is The concentrated solution containing chlorogenic acid is detected by HPLC, and the calculated content of chlorogenic acid in the tobacco powder is 1.96%.

Embodiment 3

[0032] The invention is used to extract, separate and enrich the chlorogenic acid in tobacco stems.

[0033] Take 10g of tobacco stems crushed to 80 mesh, add 250mL of water, adjust the pH value to 4 with hydrochloric acid, extract at 70°C for 2 hours; separate the tobacco extract with a conventional centrifuge, and put 210mL of the extract into a self-made flotation tank , add a mixed extraction solvent of 5 mL of n-decyl alcohol and 2 mL of pyrogallol methanol solution, pass nitrogen flotation at a flow rate of 70 mL / min, and carry out flotation for 30 minutes. The extractant in the upper layer was separated, which was the concentrated solution containing chlorogenic acid, and the content of chlorogenic acid in the tobacco stem was calculated to be 1.26% through HPLC detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com