Molecular sieve modification method capable of increasing separation factor of CH4 and N2

A separation factor and molecular sieve technology, applied in the field of molecular sieve, can solve the problems of little change in separation coefficient and no adsorption, and achieve the effect of improving separation factor and improving adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: 1g Naβ type molecular sieve is impregnated in 15ml (3M) H 2 SO 4 In the aqueous solution, stir evenly, let stand for 1 hour, filter, dry at room temperature for 24 hours, and dry at 100°C for 12 hours. After grinding, burn at a constant temperature of 500°C for 4 hours in an air atmosphere to obtain 4 2- / H-Naβ molecular sieve. In the pressure range of 330-1140mmHg, before acid modification, CH 4 and N 2 The separation factor is 1.63, H 2 SO 4 After modification, CH 4 and N 2 The separation factor increased to 2.04, 25% higher than before modification.

Embodiment 2

[0025] Embodiment 2: According to embodiment 1, 1g Naβ type molecular sieve is impregnated in H 3 BO 3 In a saturated aqueous solution, stir evenly, let stand for 1 hour, filter, dry at room temperature for 24 hours, and dry at 100°C for 12 hours. After grinding, burn at a constant temperature of 500°C for 4 hours in an air atmosphere to obtain HBO 3 - / H-Naβ molecular sieve. In the pressure range of 330 ~ 1140mmHg, CH 4 and N 2 The separation factor is 2.66, which is 63% higher than that before modification.

Embodiment 3

[0026]Embodiment 3: according to embodiment 1, 1g Naβ type molecular sieve is impregnated in 15ml (3M) NH 4 NO 3 In the aqueous solution, stir evenly, let stand for 1 hour, filter, dry at room temperature for 24 hours, and dry at 100°C for 12 hours. After grinding, burn at a constant temperature of 500°C for 4 hours in an air atmosphere to obtain + / H-Naβ molecular sieve. In the pressure range of 330 ~ 1140mmHg, CH 4 and N 2 The separation factor is 2.26, which is 38% higher than that before modification.

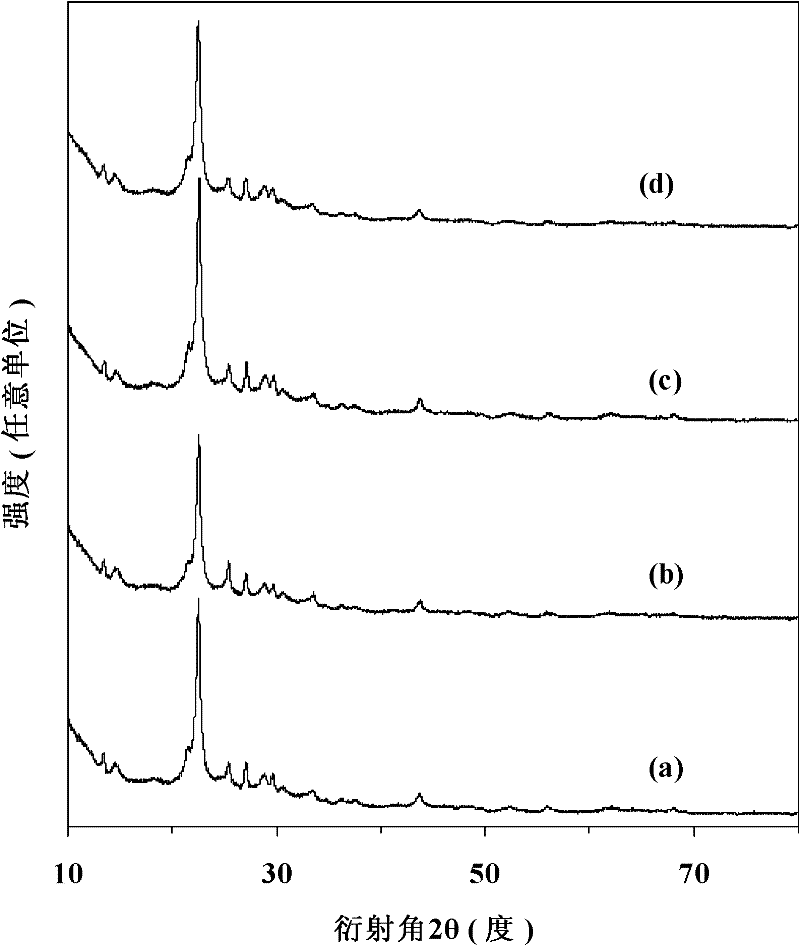

[0027] The XRD patterns of Naβ-type molecular sieves and acid-modified molecular sieves are shown in figure 1 , wherein curve (a) Naβ type molecular sieve; (b) Example 1 SO 4 2- / H-Naβ type molecular sieve; Curve (c) embodiment 2 HBO 3 - / H-Naβ type molecular sieve; Curve (d) embodiment 3H + / H-Naβ molecular sieve.

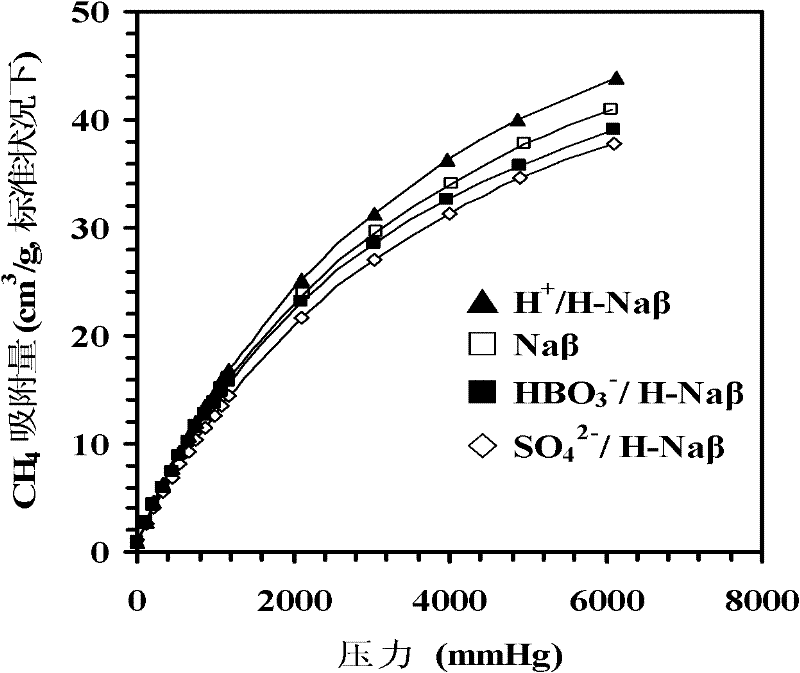

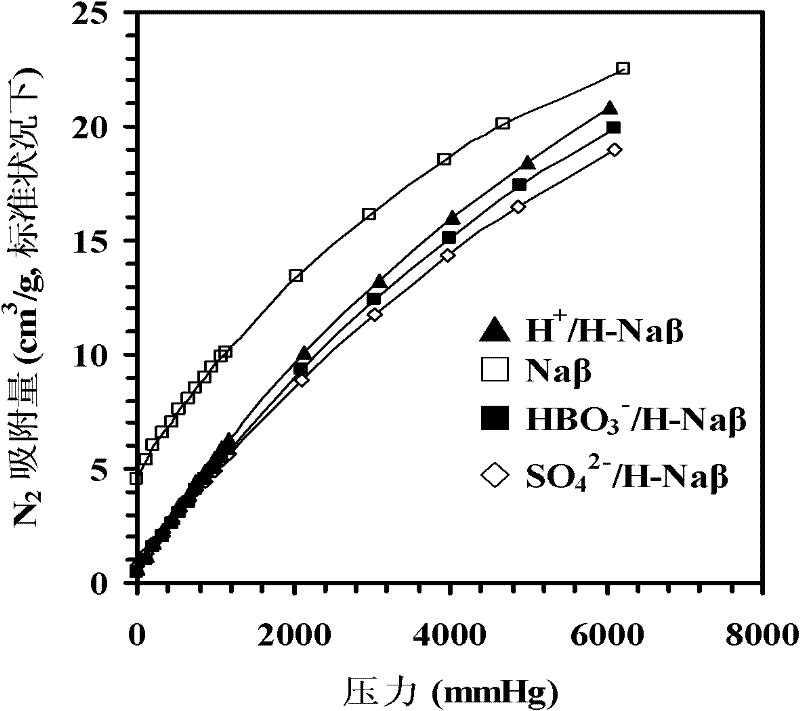

[0028] The pressure swing adsorption curves of methane on Naβ molecular sieves and acid-modified molecular sieves are shown in figure 2 , the exper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com