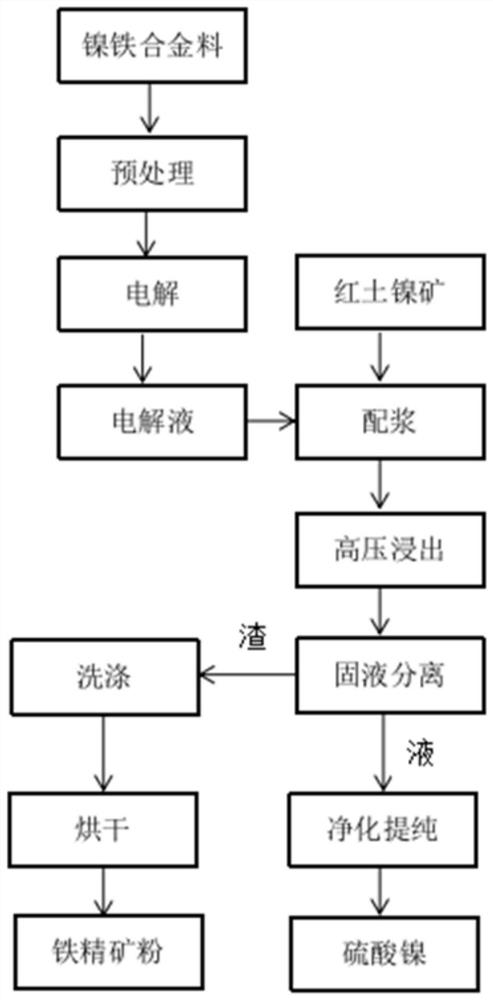

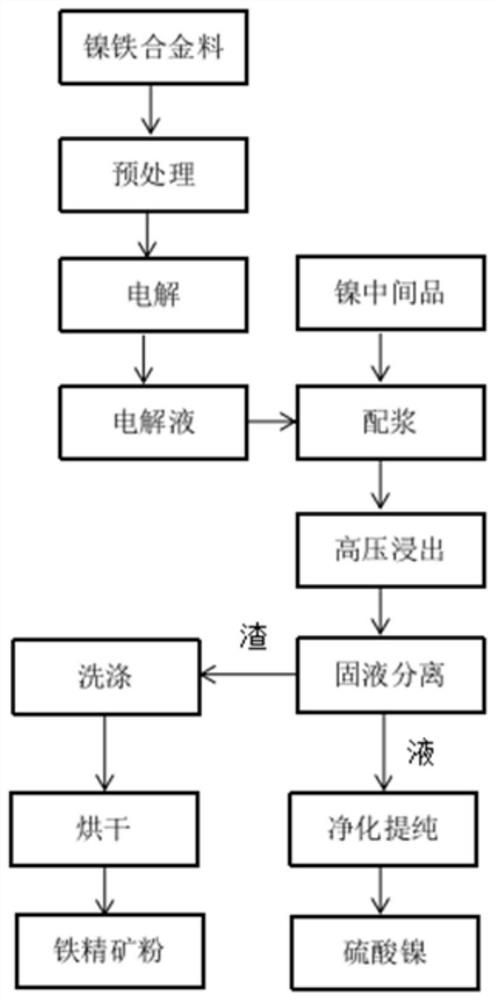

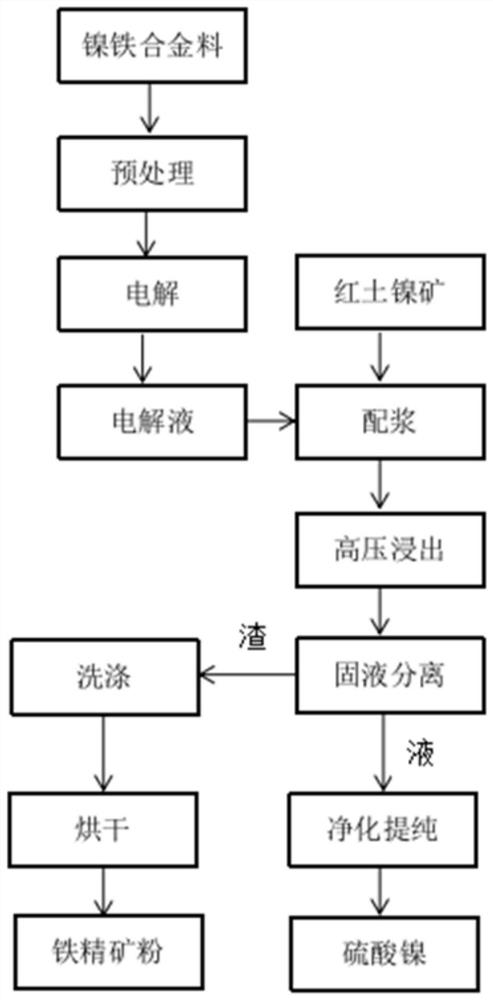

Combined treatment method for nickel-iron alloy material and nickel-containing raw material

A nickel-iron alloy and joint treatment technology, applied in the field of hydrometallurgy, can solve the problems of large consumption, achieve effective utilization, save the cost of auxiliary materials, and save the consumption of alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A joint processing method of nickel-iron alloy material and nickel-containing raw material, comprising the following steps:

[0035] (1) Put the nickel-iron alloy material into the anode basket of the electrolytic cell after pretreatment, add the initial electrolyte, energize and carry out the electrolysis reaction, and obtain the electrolyte solution; the nickel-iron alloy material is nickel pig iron mainly composed of nickel and iron, and the iron content is 85%, and the nickel content is 10%; the nickel-iron alloy material is pretreated, and the nickel-iron alloy material is broken or cut into the size that the anode basket of the electrolytic cell can accommodate. In this embodiment, the length of the alloy material is no more than 10cm. The maximum thickness does not exceed 5cm; the initial electrolyte is H + A sulfuric acid solution with a concentration of 1mol / L;

[0036] (2) After the electrolysis reaction ends, the electrolytic solution rich in nickel and iron...

Embodiment 2

[0042] A joint processing method of nickel-iron alloy material and nickel-containing raw material, comprising the following steps:

[0043] (1) Put the nickel-iron alloy material into the anode basket of the electrolytic cell after pretreatment, add the initial electrolyte, energize and carry out the electrolysis reaction, and obtain the electrolyte solution; the nickel-iron alloy material is nickel pig iron mainly composed of nickel and iron, and the iron content is 85%, and the nickel content is 10%; the nickel-iron alloy material is pretreated, and the nickel-iron alloy material is broken or cut into the size that the anode basket of the electrolytic cell can accommodate. In this embodiment, the length of the alloy material is no more than 10cm. The maximum thickness does not exceed 5cm; the initial electrolyte is H + Concentration is the sulfuric acid solution of 5mol / L;

[0044] (2) After the electrolysis reaction ends, the electrolytic solution rich in nickel and iron i...

Embodiment 3

[0050] A joint processing method of nickel-iron alloy material and nickel-containing raw material, comprising the following steps:

[0051] (1) Put the nickel-iron alloy material into the anode basket of the electrolytic cell after pretreatment, add the initial electrolyte, energize and carry out the electrolysis reaction, and obtain the electrolyte solution; the nickel-iron alloy material is a waste nickel-iron alloy product mainly composed of nickel and iron, wherein iron The nickel content is 70%, and the nickel content is 25%. The pretreatment of the nickel-iron alloy material is to crush or cut the nickel-iron alloy material into a size that can be accommodated by the anode basket of the electrolytic cell. In this embodiment, the length of the alloy material is not more than 5cm, the maximum thickness does not exceed 2cm; the initial electrolyte is H + A sulfuric acid solution with a concentration of 10mol / L;

[0052] (2) After the electrolytic reaction finishes, the ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com